1.How does the PTO Series U-Joint handle vibration and shock in high-speed applications?

As an important component in the transmission system, PTO Series U-Joints (Power Take-Off Series Universal Joints) have demonstrated significant technical advantages and engineering innovation in dealing with vibration and shock issues in high-speed applications. In the industrial and agricultural fields, especially in equipment that require high-efficiency transmission and stable operation, such as agricultural machinery, heavy-duty vehicles, and engineering equipment, the design and material selection of PTO Series U-Joints are crucial and directly affect the overall system. performance and reliability.

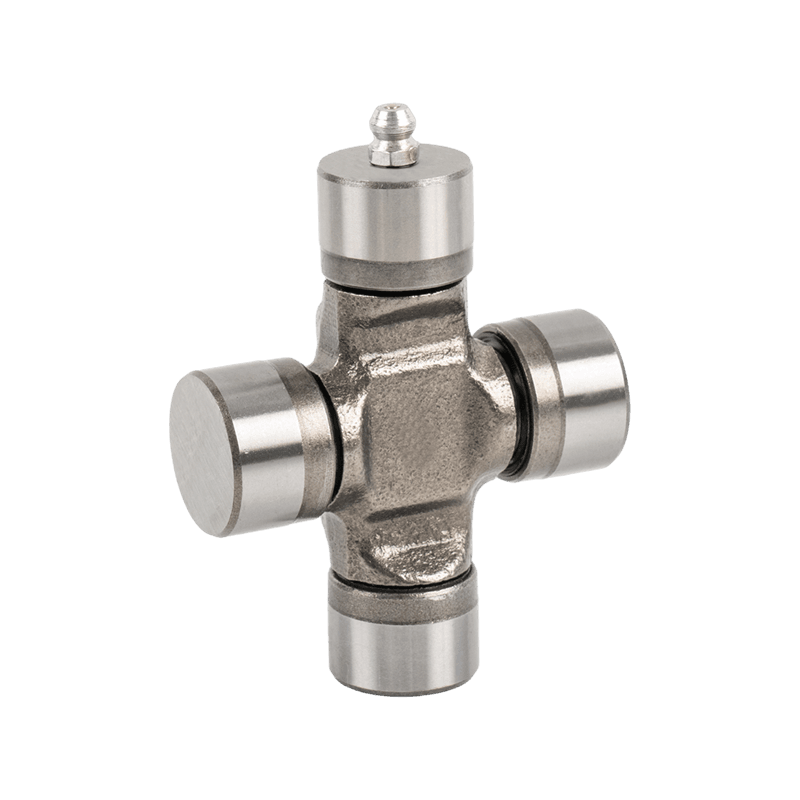

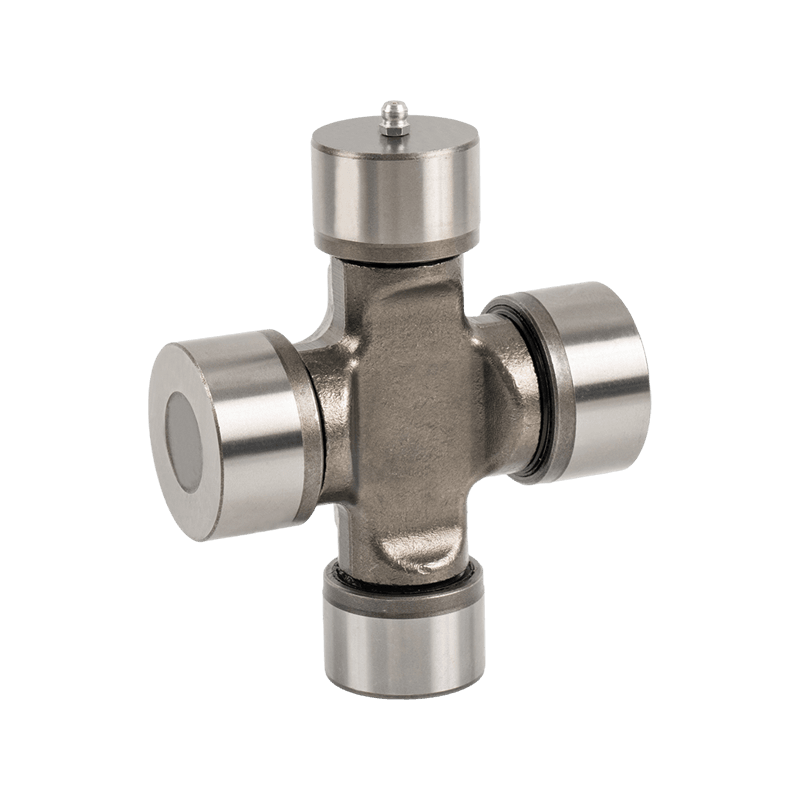

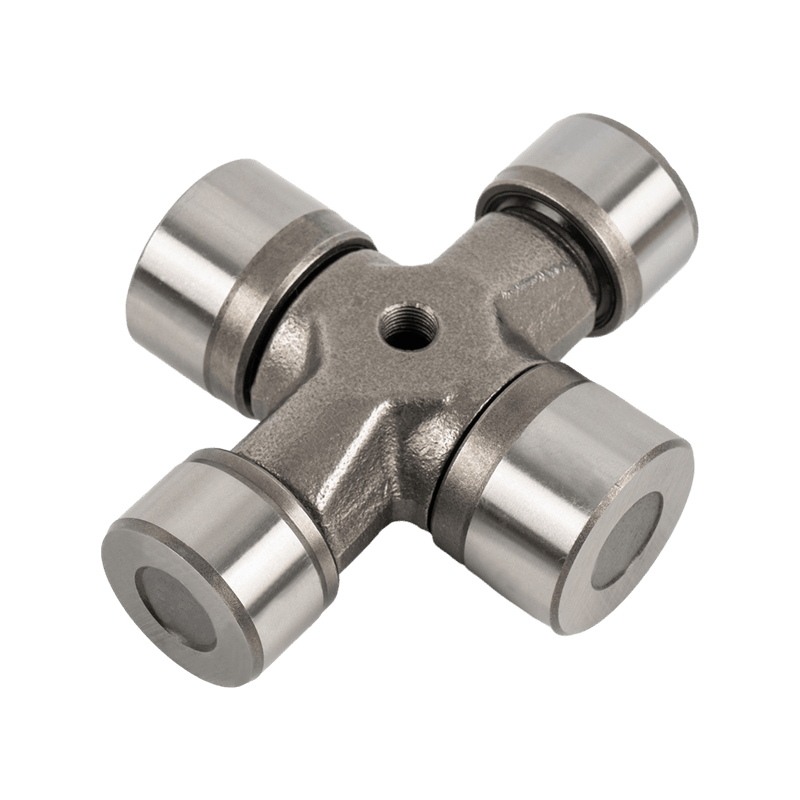

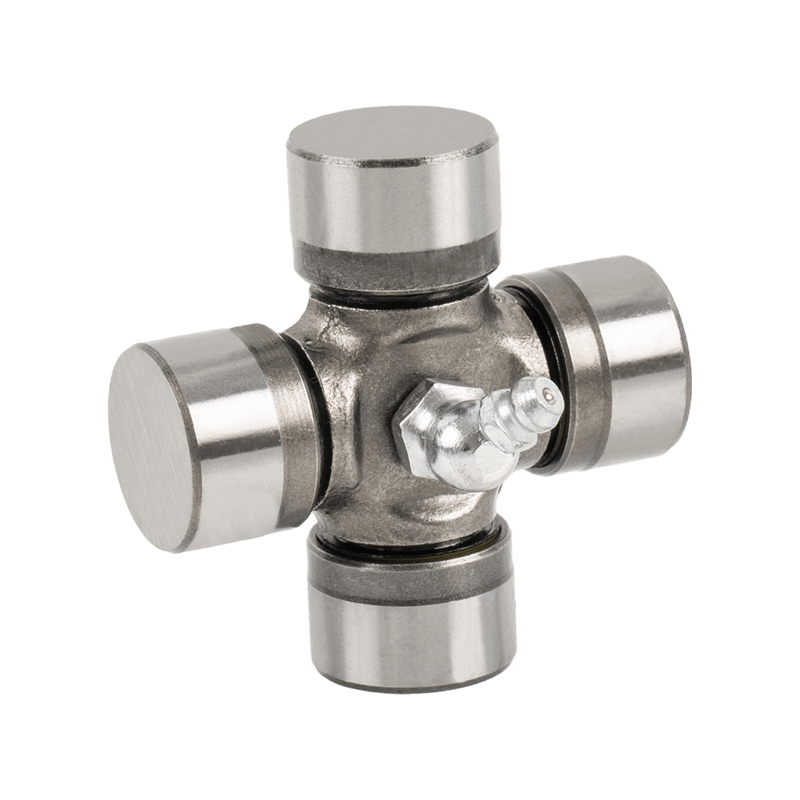

PTO Series U-Joints are designed with how to effectively suppress and manage vibration and shock. Vibration and shock at high speeds can have negative effects on equipment, including increased wear, reduced efficiency and even damage to critical components. To address these challenges, PTO Series U-Joints often feature complex internal structures and shock-absorbing mechanisms designed to minimize the transmission of vibration and shock. These designs are not only to improve user experience, but also to effectively extend the service life and stability of the device.

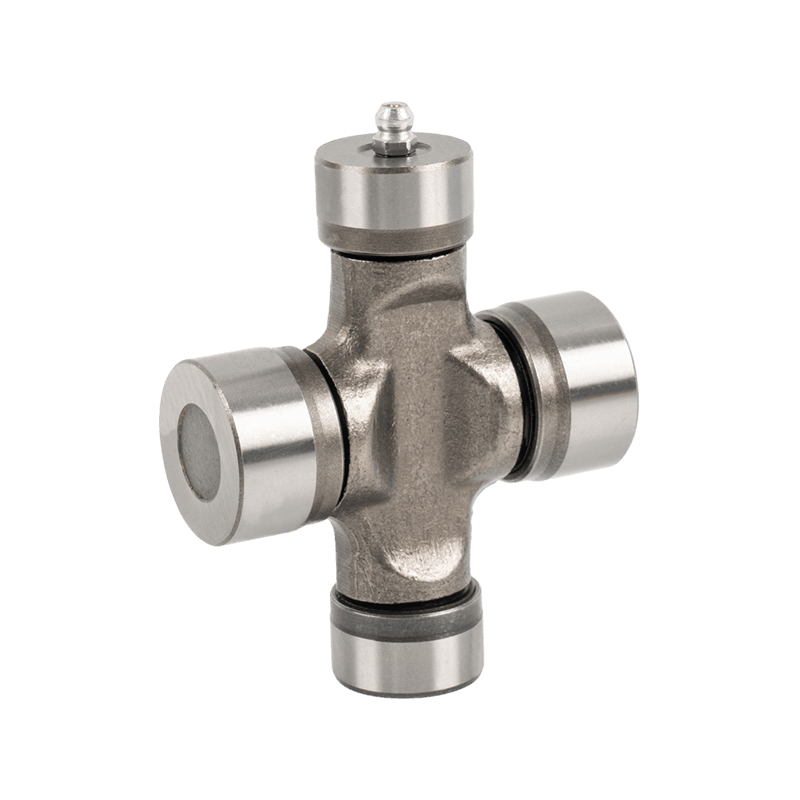

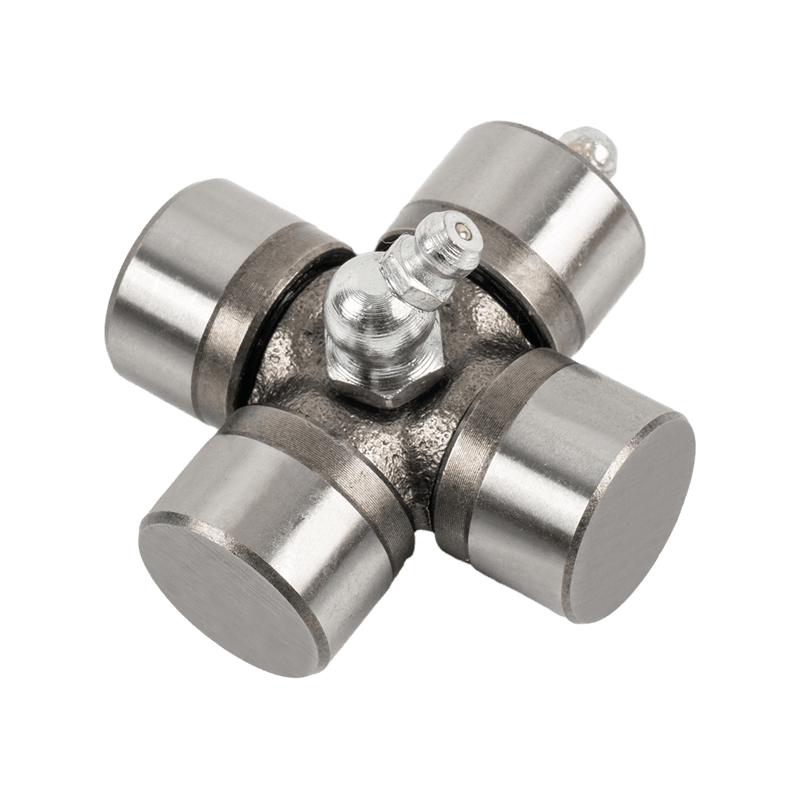

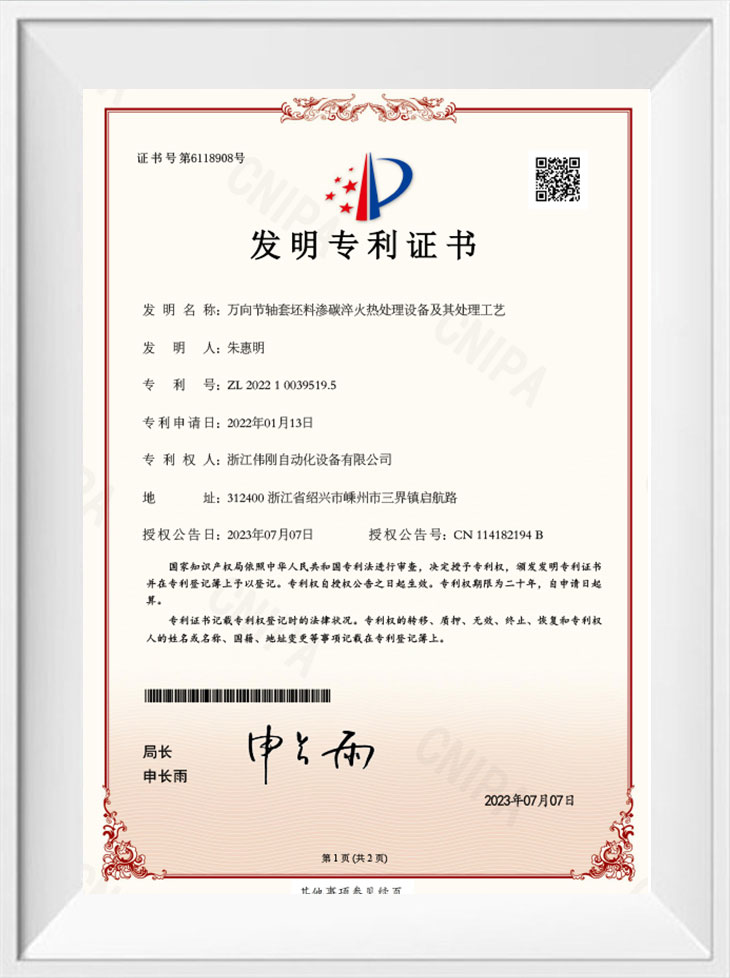

Material selection is critical to the performance of PTO Series U-Joints. These components are usually made of wear-resistant materials such as high-strength alloy steel or cast iron to ensure they can withstand high-intensity working conditions during high-speed operation and long-term use. These materials not only resist stresses caused by vibration and impact, but also maintain stable mechanical properties under a variety of environmental conditions. In addition, precise processing and dynamic balancing are also key factors to ensure that PTO Series U-Joints reduce vibration and imbalance during operation, thereby improving overall transmission efficiency and reliability.

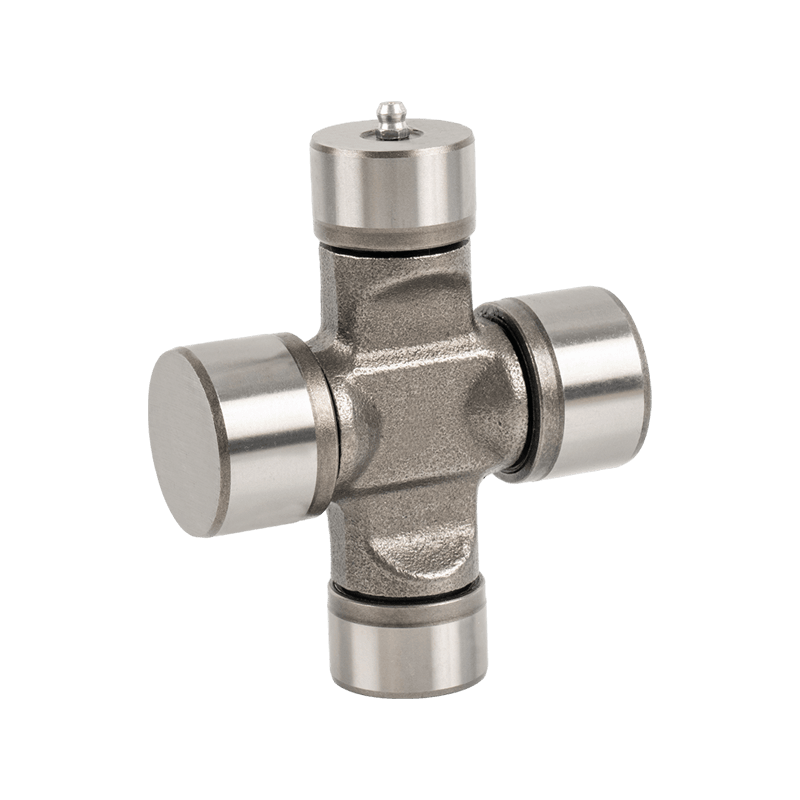

An effective lubrication system is another key factor that directly affects the performance of PTO Series U-Joints in high-speed applications. Proper lubrication can effectively reduce friction and wear, reduce heat and energy losses caused by friction, and thereby reduce vibration and impact. Designers usually consider the design of the lubrication system to ensure that it can continuously provide necessary lubrication and protection to PTO Series U-Joints during operation to cope with various working conditions and load changes.

2.What are the advantages of PTO Series U-Joints compared with traditional mechanical couplings?

As a key component in the transmission system, PTO Series U-Joints (Power Take-Off Series Universal Joints) have demonstrated significant technical advantages and application flexibility compared with traditional mechanical couplings. In the industrial and agricultural fields, especially those equipment that require high-efficiency transmission and stable operation, the design and performance advantages of PTO Series U-Joints are significant.

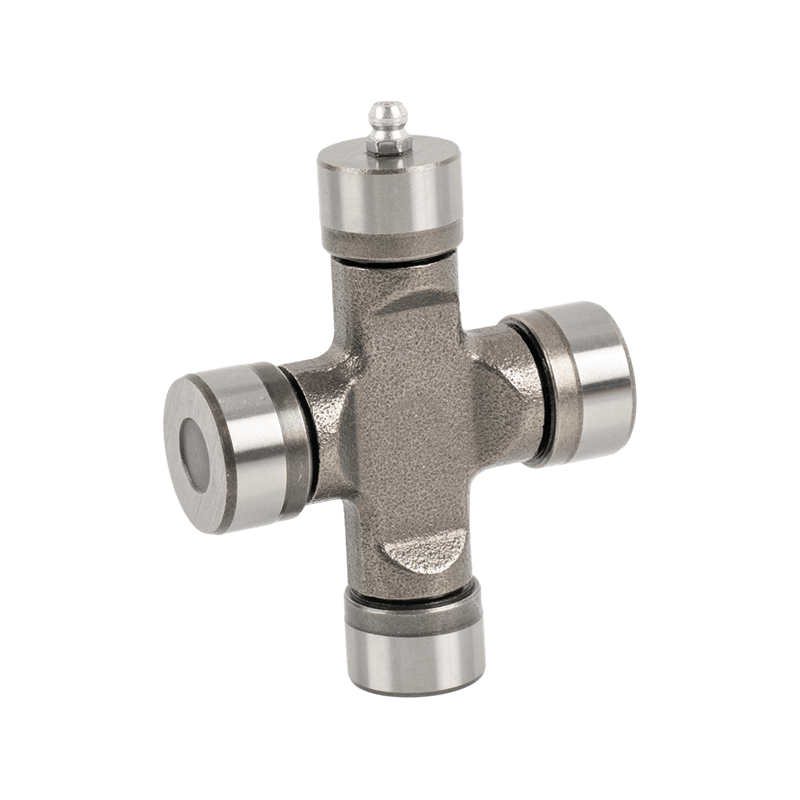

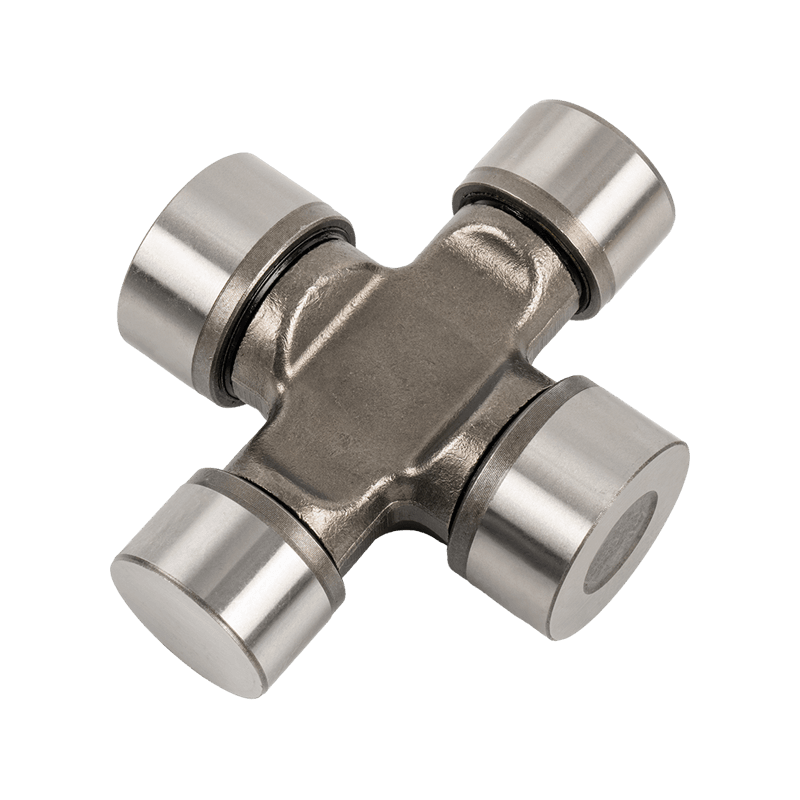

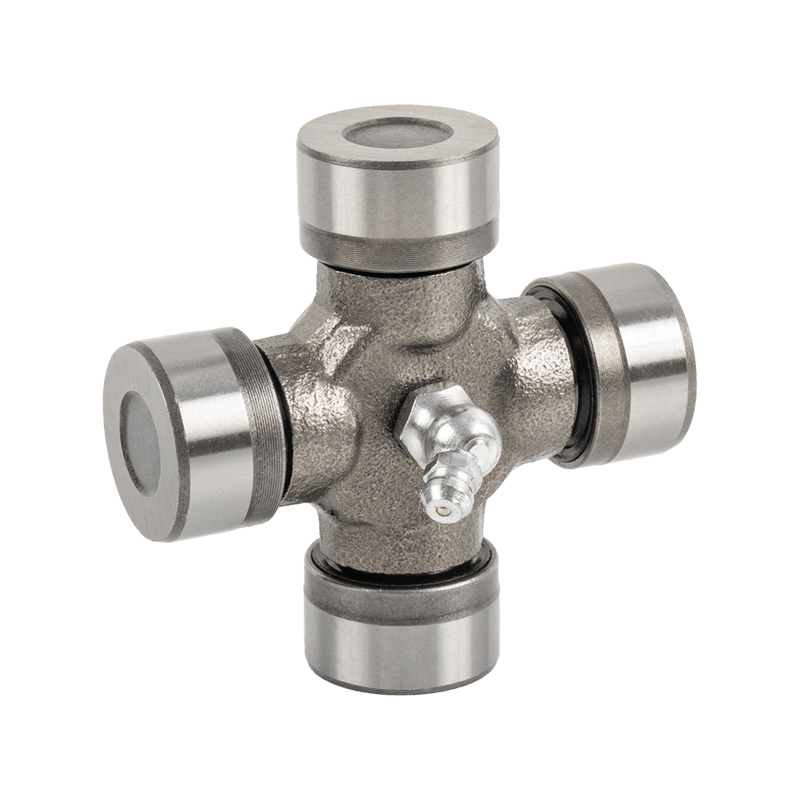

PTO Series U-Joints handle angular misalignment and misalignment between drive shafts. Traditional mechanical couplings usually require the axes to be in a straight line and well aligned, while PTO Series U-Joints, through their special design and structure, can tolerate a certain degree of axis offset and angle changes, which makes them easy to install and operate. Be more flexible and adaptable in the process. This feature is particularly important in modern mechanical engineering as it allows more complex transmission arrangements and a wider range of application scenarios.

PTO Series U-Joints are designed to withstand and transmit high torque. Whether used in tillage equipment for agricultural machinery or power transmission systems in heavy-duty trucks, these universal joints are capable of transmitting high power reliably. Its internal structure and selected materials, such as high-strength alloy steel or cast iron, ensure stability and durability under high loads and long periods of operation. In contrast, traditional mechanical couplings may perform poorly under high load and torque conditions, requiring more frequent maintenance and replacement.

PTO Series U-Joints have excellent vibration and shock absorption capabilities. Through their specially designed shock-absorbing mechanism and internal structure, these universal joints can effectively reduce the impact of vibration and shock caused by high-speed operation on the transmission system. This capability not only helps protect adjacent mechanical components from vibration damage, but also increases overall system stability and reliability. Traditional mechanical couplings often require additional vibration absorbing devices or complex adjustments to achieve similar results.

Additionally, PTO Series U-Joints offer wide adaptability and flexibility. They can connect different types and sizes of drive shafts to meet the needs of different applications. Whether in harvesting machinery in agriculture or concrete mixers on construction sites, these universal joints provide reliable power transmission solutions. In contrast, traditional mechanical couplings usually require specific sizes and types to be selected based on specific transmission requirements, and their adaptability is limited.

English

English 中文简体

中文简体