1. Understanding the Function of U-Joints

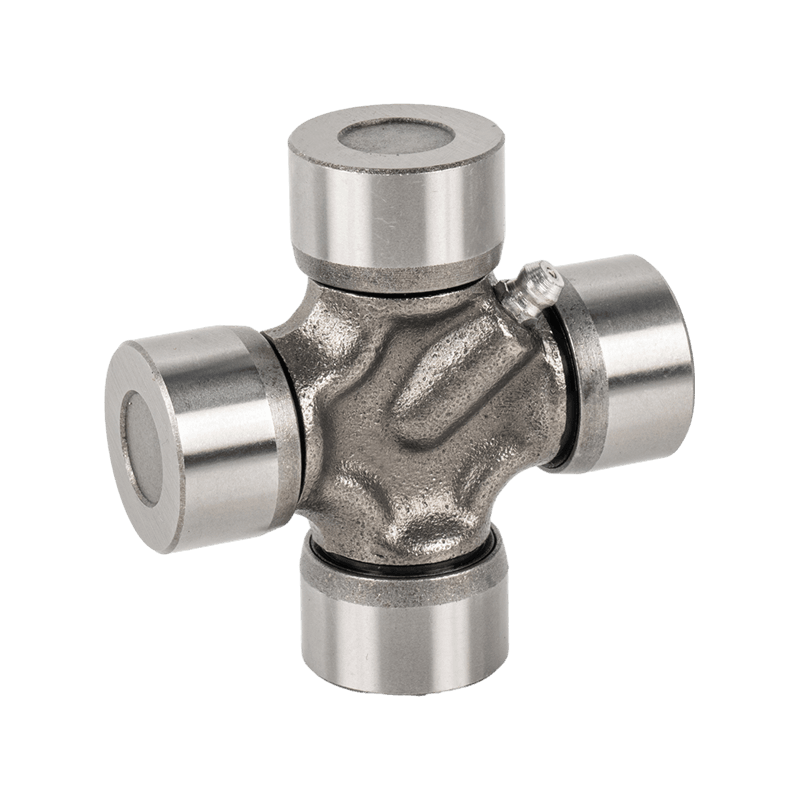

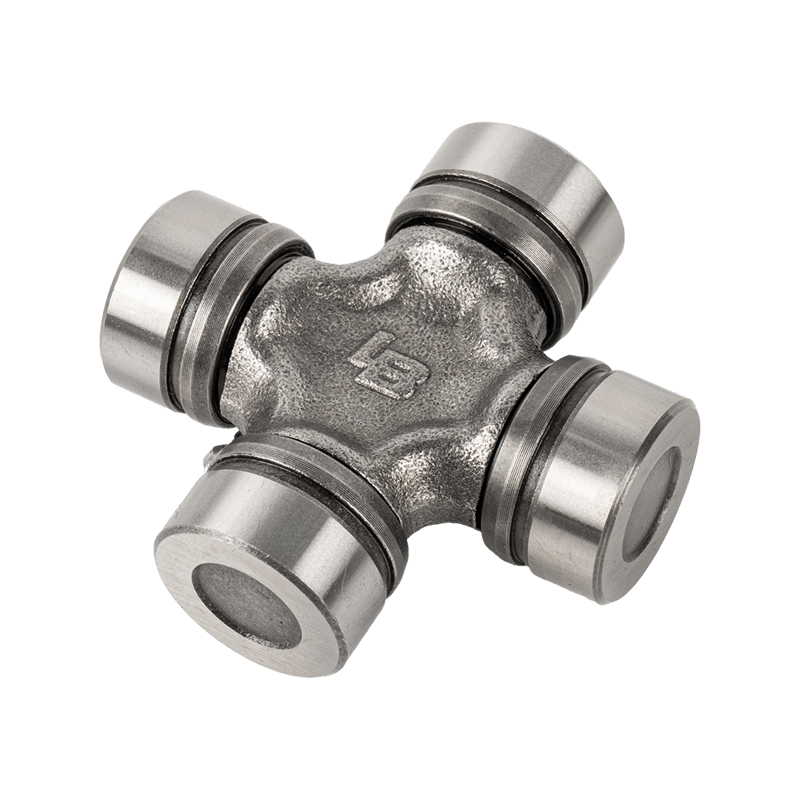

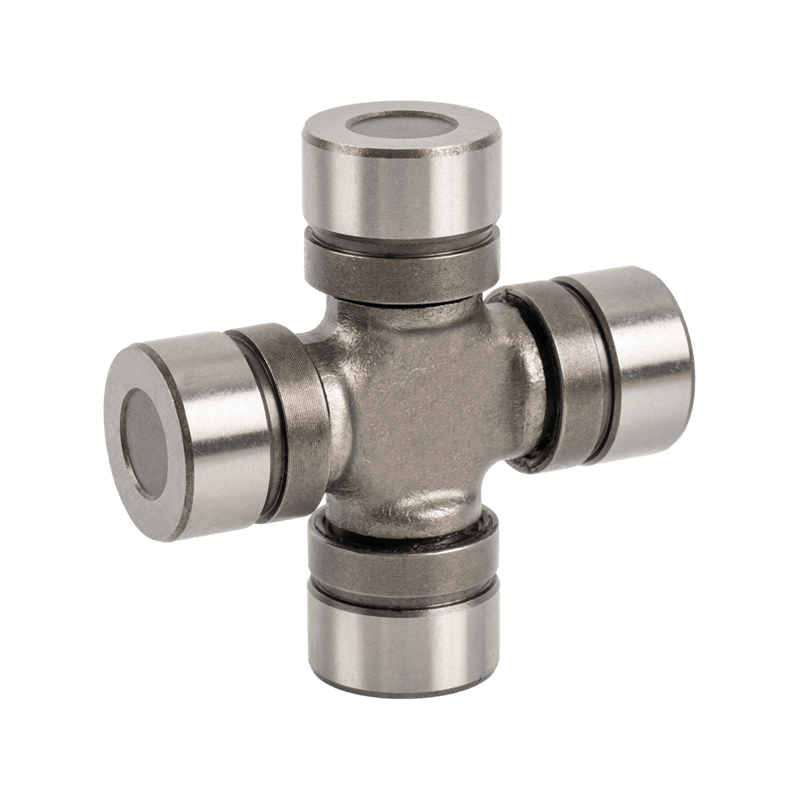

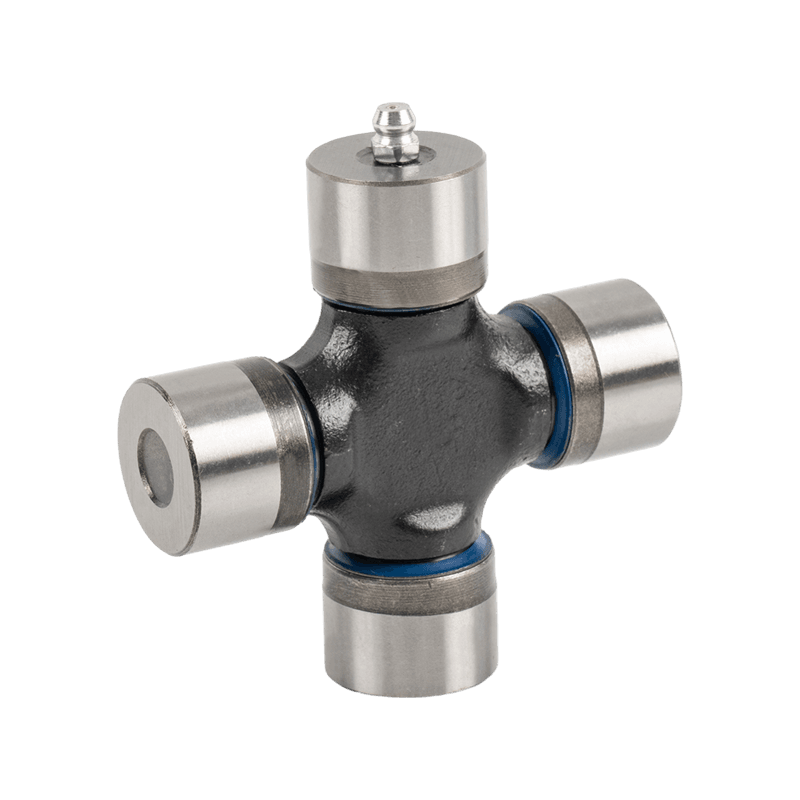

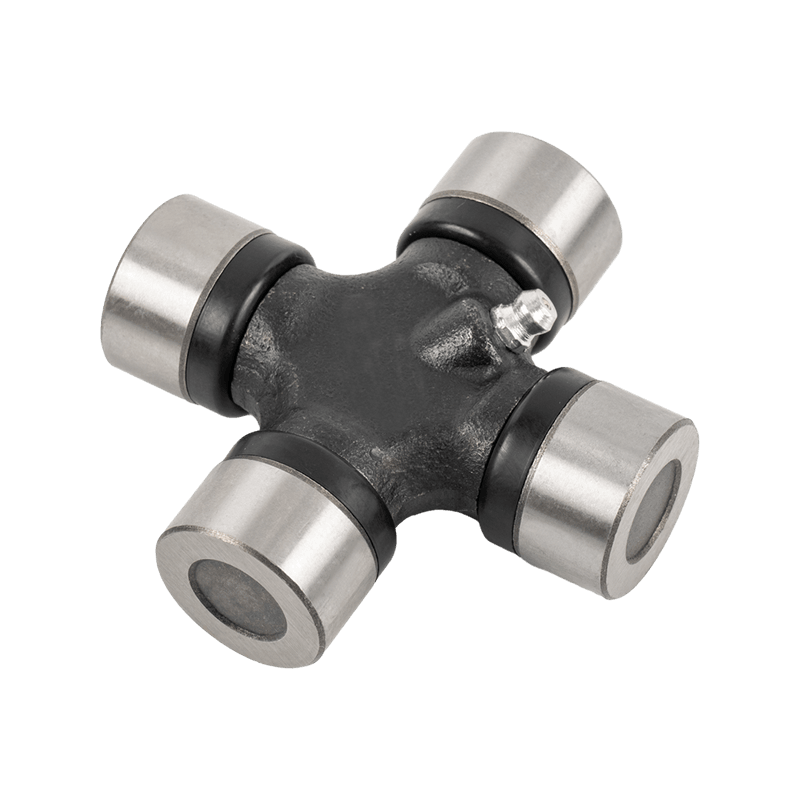

Universal joints (U-joints) are a pivotal element in the drivetrain of vehicles, playing an essential role in the transmission of power between misaligned shafts. Their ability to accommodate angular misalignments makes them indispensable for ensuring smooth and efficient power delivery from the transmission to the wheels. U-joints are designed as a flexible coupling between two shafts that allows for changes in angle between the shafts. The basic design includes a cross-shaped component, known as the spider, which connects to the yokes on the ends of the shafts via bearings. This configuration allows the shafts to move relative to each other while maintaining a constant rotational speed. When a vehicle is in motion, especially over uneven terrain, the drivetrain components are subjected to various forces and movements. The U-joint's ability to bend in any direction enables the drive shaft to continue transmitting torque, even when the angles between the transmission and the differential change. This flexibility is vital for vehicles with rear-wheel drive, front-wheel drive, and all-wheel drive systems, as it ensures continuous power delivery regardless of the driving conditions.

a)Addressing Misalignment and Suspension Movements: One of the primary challenges in vehicle dynamics is the misalignment of drivetrain components caused by suspension movements. As the suspension system absorbs shocks and adjusts to the road surface, the angles between the transmission, drive shaft, and differential can change. U-joints are engineered to handle these changes, maintaining the integrity of the power transfer. For example, in a rear-wheel-drive vehicle, the drive shaft must transmit power from the transmission at the front to the differential at the rear. As the rear axle moves up and down in response to road conditions, the angles at both ends of the drive shaft vary. The U-joint's ability to pivot in multiple directions allows it to accommodate these movements without causing undue stress on the drivetrain components.

b)Smoothing Power Delivery and Reducing Vibrations: U-joints also play a crucial role in reducing vibrations and ensuring smooth power delivery. In the absence of U-joints, any angular misalignment between the drive shafts would result in uneven rotational speeds, causing vibrations and potential damage to the drivetrain. The unique design of U-joints allows for the equalization of rotational speeds between the shafts, thus minimizing vibrations and enhancing the overall driving experience. In high-performance and off-road vehicles, where the drivetrain is subjected to extreme conditions, the reliability of U-joints becomes even more critical. Advanced U-joint designs, such as constant velocity (CV) joints, have been developed to offer even greater flexibility and performance in such demanding environments. These joints provide a constant rotational speed irrespective of the angle, further enhancing the vehicle's capability to handle tough terrains.

2. Unique Features of Japanese U-Joints

Japanese vehicle U-joints are renowned globally for their exceptional quality, durability, and engineering precision. These attributes are the result of advanced manufacturing techniques, stringent quality control processes, and a commitment to continuous improvement.

a)Advanced Material Selection: The foundation of a high-quality U-joint lies in the materials used in its construction. Japanese manufacturers meticulously select premium-grade materials such as high-strength alloy steels. These materials provide superior resistance to wear, fatigue, and impact, ensuring that the U-joints can withstand the rigorous demands of automotive applications. The use of advanced metallurgy also enhances the U-joints' ability to perform reliably under extreme temperatures and harsh environmental conditions.

b)Precision Engineering and Machining: Precision is a hallmark of Japanese manufacturing, and U-joints are no exception. The components of Japanese U-joints are engineered and machined to exacting tolerances, ensuring perfect fits and optimal performance. State-of-the-art CNC machining techniques are employed to achieve the required precision in dimensions and surface finishes. This meticulous attention to detail minimizes internal friction, reduces wear, and extends the operational lifespan of the U-joints.

c)Superior Bearing Technology: Bearings are a critical component of U-joints, and Japanese U-joints incorporate advanced bearing technologies to enhance their performance. These bearings are designed to provide smooth and efficient rotational movement while minimizing friction and heat generation. The use of high-quality needle or roller bearings, often with specialized coatings and treatments, ensures consistent performance and durability. Additionally, precision bearing alignment reduces the risk of premature failure and ensures the U-joints operate quietly and efficiently.

d)Innovative Design Features: Innovation is a key driver in the development of Japanese U-joints. Manufacturers continuously seek to improve design features to enhance performance and reliability. Examples include the integration of multi-axis flexibility to accommodate complex drivetrain movements and the use of specialized coatings to reduce friction and improve wear resistance. These design innovations ensure that Japanese U-joints not only meet but often exceed the performance expectations of modern vehicles.

English

English 中文简体

中文简体