How is the KOREA VEHICLE u-joint precisely machined

In the precision manufacturing system of the Korean automotive industry, U-Joint is the core component of the transmission system. Its machining accuracy and quality are directly related to the performance and reliability of the entire vehicle. The excellent precision machining technology of KOREA VEHICLE U-JOINT ensures the efficient and smooth operation of the transmission system.

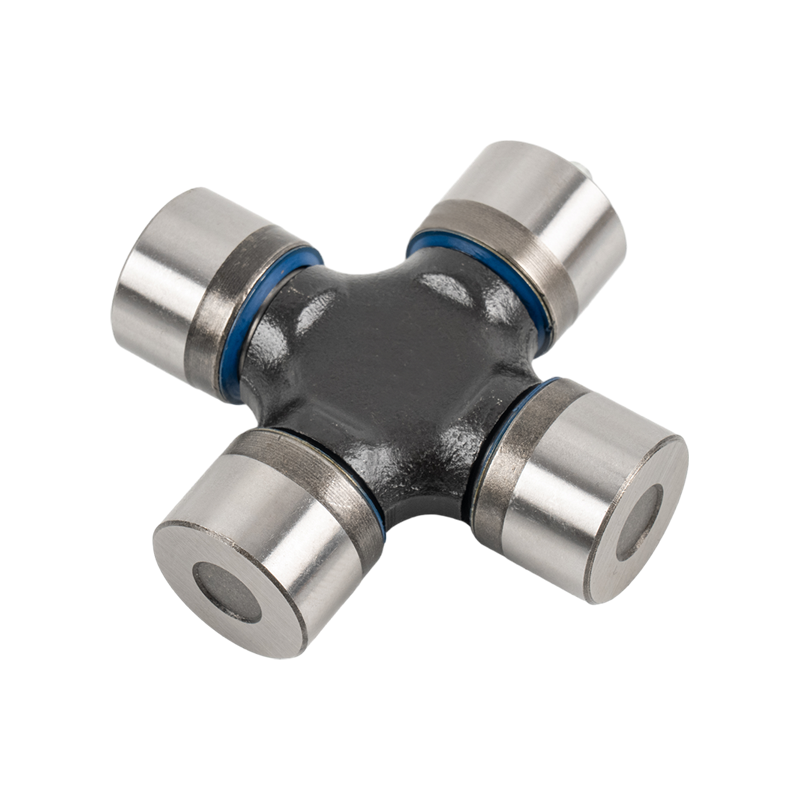

In the automotive transmission system, U-Joint needs to withstand complex mechanical environments and variable working conditions, and machining accuracy and surface quality are crucial. Precision machining can not only ensure the geometric size and shape accuracy of U-Joint, but also improve its surface finish and wear resistance, thereby extending its service life, reducing noise and vibration, and improving transmission efficiency. The machining of KOREA VEHICLE U-JOINT begins with the selection of high-quality materials. KOREA VEHICLE U-JOINT usually uses high-strength and high-wear-resistant alloy steel as raw materials. These materials have good mechanical properties and machining properties. After the raw materials enter the factory, they will undergo strict inspection and pretreatment, including stress relief annealing, surface cleaning and other processes to ensure that there are no defects inside the material and the surface finish meets the requirements.

The precision machining process of KOREA VEHICLE U-JOINT mainly includes the following links.

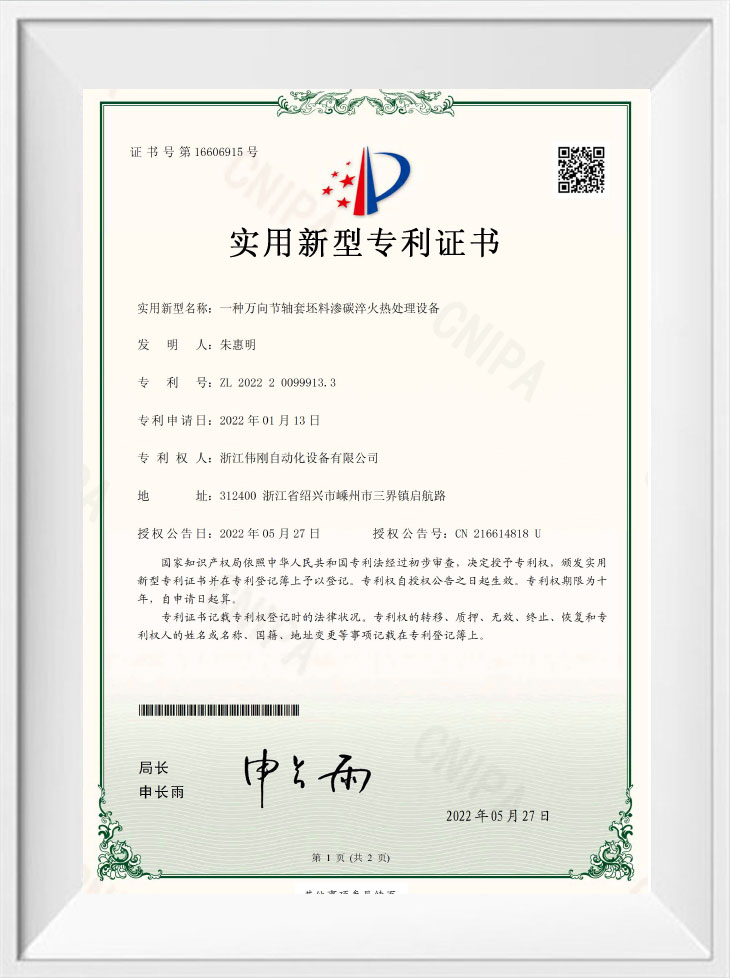

Advanced CNC machine tools are used for rough machining and finishing, and the motion trajectory and cutting parameters of the machine tools are controlled by programming to achieve high-precision and high-efficiency machining. CNC machining not only improves machining accuracy and consistency, but also reduces the impact of human factors on machining quality. During the machining process, multiple heat treatment processes will be carried out, including quenching and tempering. These heat treatment processes can improve the internal structure and mechanical properties of the material and improve the hardness and wear resistance of the U-Joint. By accurately controlling the heat treatment parameters, the generation of defects such as deformation and cracks can also be reduced.

In order to further improve the surface finish and dimensional accuracy of the U-JOINT, a precision grinding process will be used. The surface of the U-JOINT is finely ground by high-speed rotation and micro-feeding of the grinding wheel. Precision grinding can remove burrs and tiny defects generated during the machining process, making the surface of the U-JOINT smoother and flatter. After completing the processing of a single part, assembly and debugging work is required. Through precise assembly technology and advanced debugging equipment, U-JOINT is ensured to work perfectly with other parts of the transmission system. U-JOINT will also be subjected to strict performance testing and quality inspection to ensure that it meets the design requirements and usage standards. In the processing of KOREA VEHICLE U-JOINT, quality control and inspection are indispensable and important links. By adopting advanced testing equipment and technical means, each link in the processing process is monitored and data analyzed in real time. Once an abnormal situation or quality problem is found, corresponding measures will be taken immediately for rectification and optimization. Strict sampling and comprehensive testing will also be carried out on the finished product to ensure that the quality and performance of U-JOINT meet the standards.

The precision processing technology of KOREA VEHICLE U-JOINT not only improves the processing accuracy and surface quality of the product, but also brings excellent transmission performance and service life. Its high precision, low noise and low vibration make the transmission system more stable and reliable; its high wear resistance and high load-bearing capacity enable U-JOINT to operate stably for a long time under harsh working conditions. These outstanding performances have enabled KOREA VEHICLE U-JOINT to occupy an important position in the Korean and even global automotive markets.

Why KOREA VEHICLE u-joint is a practitioner of environmentally friendly life

Environmental protection and energy saving means to minimize the impact on the environment and reduce energy consumption while meeting the production and living needs of human beings. This concept has been deeply rooted in the hearts of the people and has become a common pursuit of the development of all walks of life. In the automotive industry, environmental protection and energy saving not only means reducing exhaust emissions and reducing fuel consumption, but also involves the full-scale optimization of various links such as vehicle design, manufacturing, and use.

KOREA VEHICLE U-JOINT is a key component of the automotive transmission system. Its technical advantages and performance characteristics directly determine the transmission efficiency and environmental performance of the vehicle. U-Joint uses advanced materials and manufacturing processes, and has the characteristics of high strength, high wear resistance, and low friction coefficient. These characteristics allow U-Joint to reduce energy loss and improve transmission efficiency in the process of transmitting power, thereby reducing the fuel consumption of the vehicle. The precision machining process of KOREA VEHICLE U-JOINT ensures high consistency of its geometric dimensions and shape accuracy. This consistency not only improves the reliability and durability of U-Joint, but also reduces the noise and vibration caused by wear and looseness. The reduction of noise and vibration not only improves driving comfort, but also indirectly reduces the energy consumption and emissions of the vehicle.

The environmental protection and energy-saving characteristics of KOREA VEHICLE U-JOINT have been widely used in daily life. In the field of passenger cars, the efficient transmission performance of U-Joint enables the vehicle to maintain low fuel consumption and emissions under different road conditions and driving modes. This is especially important for daily vehicle use scenarios such as urban commuting and long-distance travel. By reducing fuel consumption and emissions, U-Joint has made positive contributions to improving urban air quality and reducing greenhouse gas emissions. In the field of commercial vehicles, KOREA VEHICLE U-JOINT also plays an important role. Due to the characteristics of large load capacity and long mileage, commercial vehicles have more stringent requirements on the transmission system. The high efficiency and reliability of U-Joint enables commercial vehicles to reduce fuel consumption and emission pollution during transportation, thereby reducing operating costs and improving environmental benefits. With the rise of new energy vehicles, KOREA VEHICLE U-JOINT has also demonstrated its environmental protection and energy-saving advantages in this field. New energy vehicles use motor drive systems instead of traditional fuel engines, and U-Joint is a connecting component between the motor and the drive shaft. Its efficient transmission performance is of great significance for improving the range of new energy vehicles and reducing energy consumption.

KOREA VEHICLE U-JOINT's unique technical advantages and wide application scenarios have made it a firm practitioner of environmental protection and energy conservation. It not only plays an important role in improving automobile transmission efficiency, reducing fuel consumption and emissions, but also makes positive contributions to promoting the green transformation of the automotive industry and promoting sustainable development. With the continuous advancement of science and technology and the continuous improvement of environmental awareness, KOREA VEHICLE U-JOINT will continue to move forward on the road of environmental protection and energy conservation, and contribute to the sustainable development of human society.

English

English 中文简体

中文简体