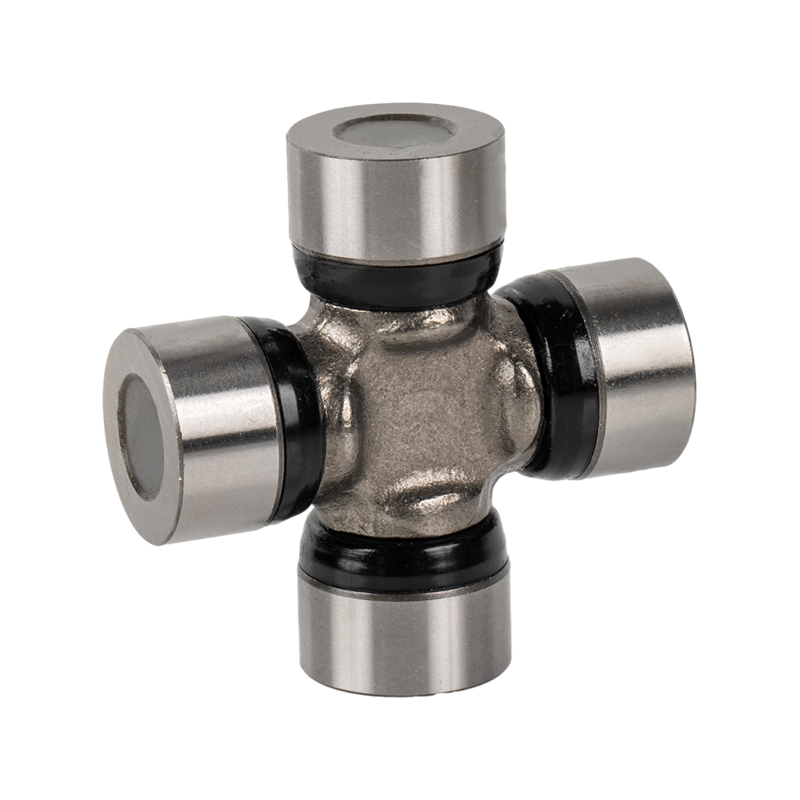

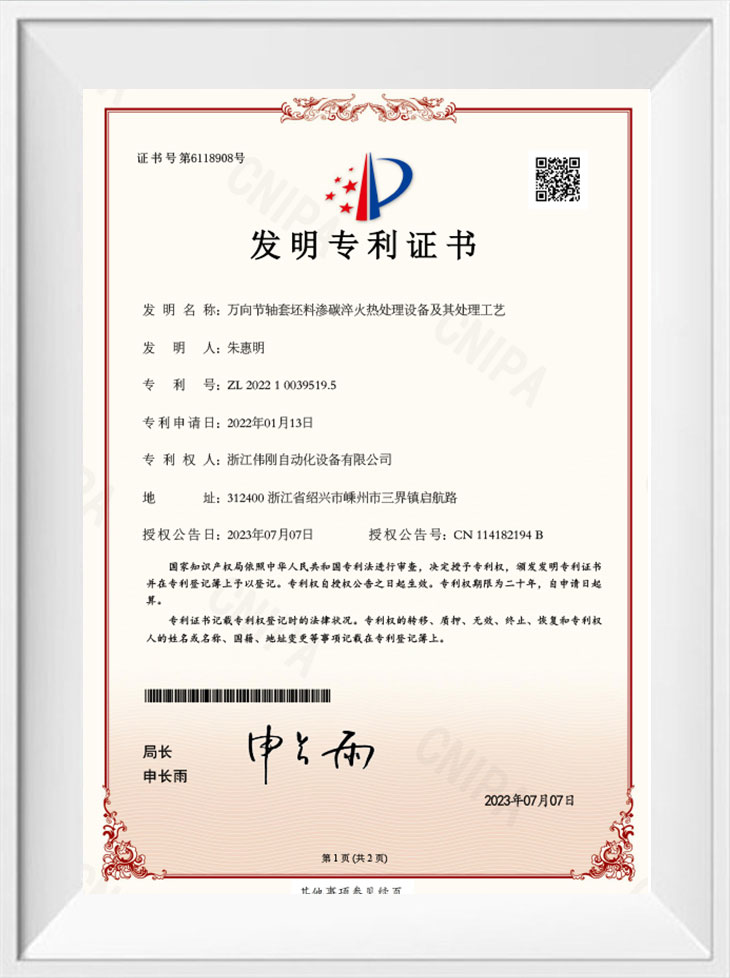

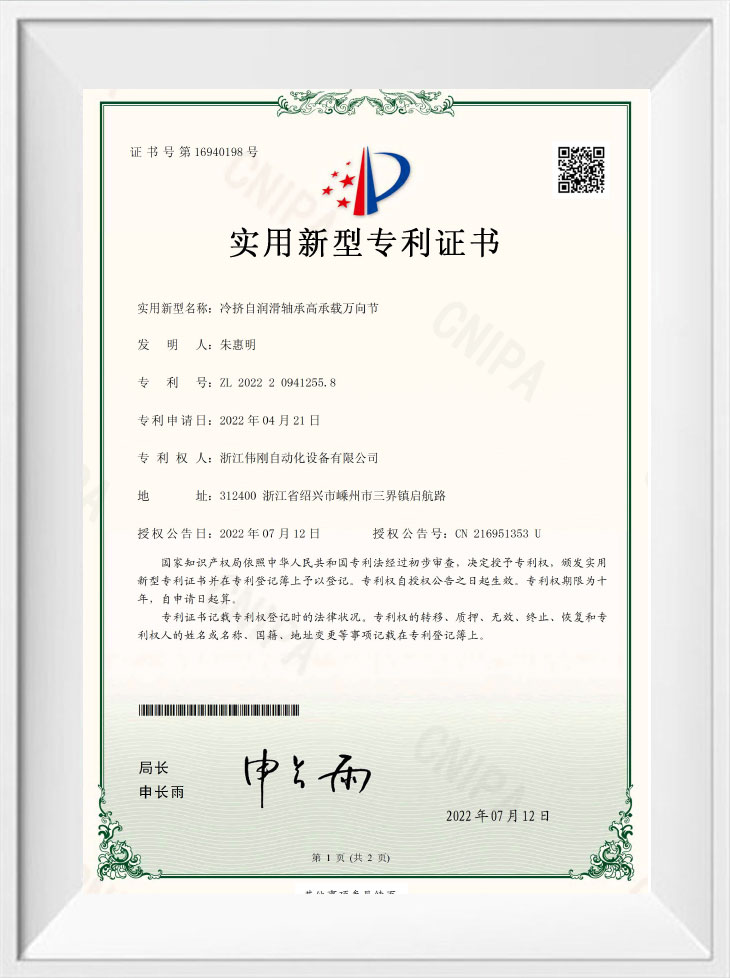

As China RUSSIA VEHICLE U-Joint manufactures and RUSSIA VEHICLE U-Joint factory, Zhejiang Weigang Technology Co., Ltd. (formerly Hangzhou Xiaoshan Weigang Auto Parts Co., Ltd.) was founded in 1997, located in Qianjiang River, Ningwei Town covers an area of 15,000 square meters, producing "wave" (LB) universal joints, bearings and other auto parts, with the "market-oriented, customer-driven, technology-based" business policy, the implementation of ISO9001 national quality system standards, product quality excellence.

-- followed the quality system standard ISO9001:2008 in 2014.

--- updated in 2018 to implement the quality system standard IATF16949:2016

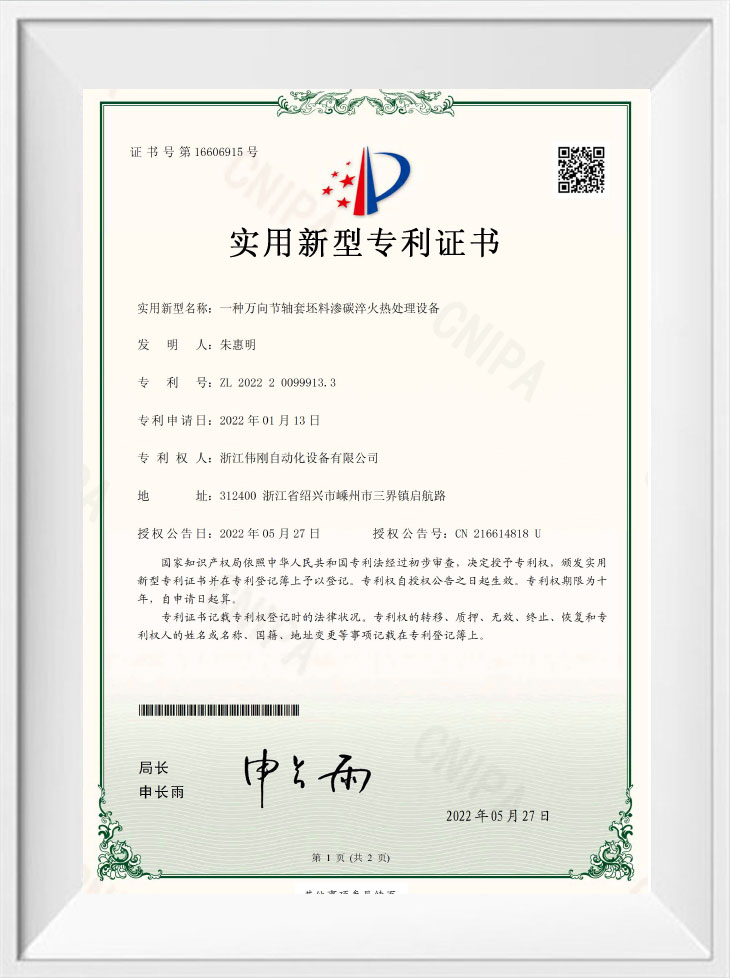

--- changed its name to Zhejiang Weigang Technology Co., Ltd. in September 2018 Moved to No. 77, Qihang Road, Sanjie Town, Shengzhou City, Shaoxing City, the company covers an area of 43,000 square meters, with an annual production of 4.50-5.5 million u- joints.

6 production line of Forge equipment ,CNC lathes is over 50 sets,more than 60 sets grinding machines, several automated machinery and equipment, 6 new forging lines, 2 assembly lines, etc., following the business philosophy of "high starting point investment, high-precision equipment, high-level talents, high-grade products", and adhering to domestic and foreign market expansion.

English

English 中文简体

中文简体