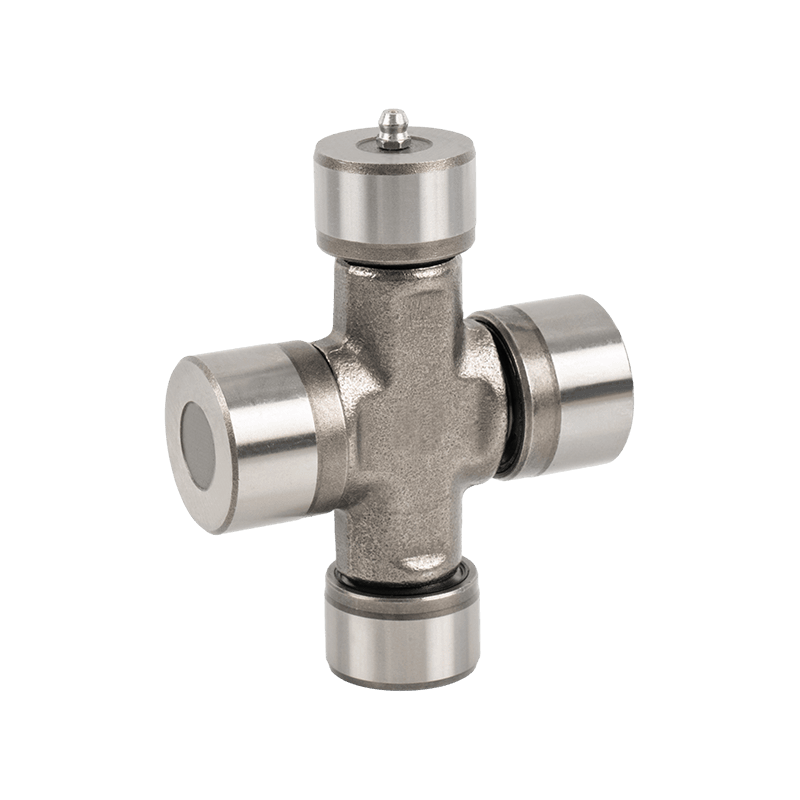

Why does Agricultural Machinery U-Joint have high load-bearing capacity?

In the vast farmland, agricultural machinery is like a hardworking farmer, cultivating the land and sowing hope day after day. The efficient operation of these huge machines is inseparable from their precise and powerful internal transmission system. As a key component in this system, the high-load-bearing design of Agricultural Machinery U-Joint ensures the continuity and stability of power transmission, becoming an indispensable "power link" for agricultural machinery.

1. Material selection and reinforcement

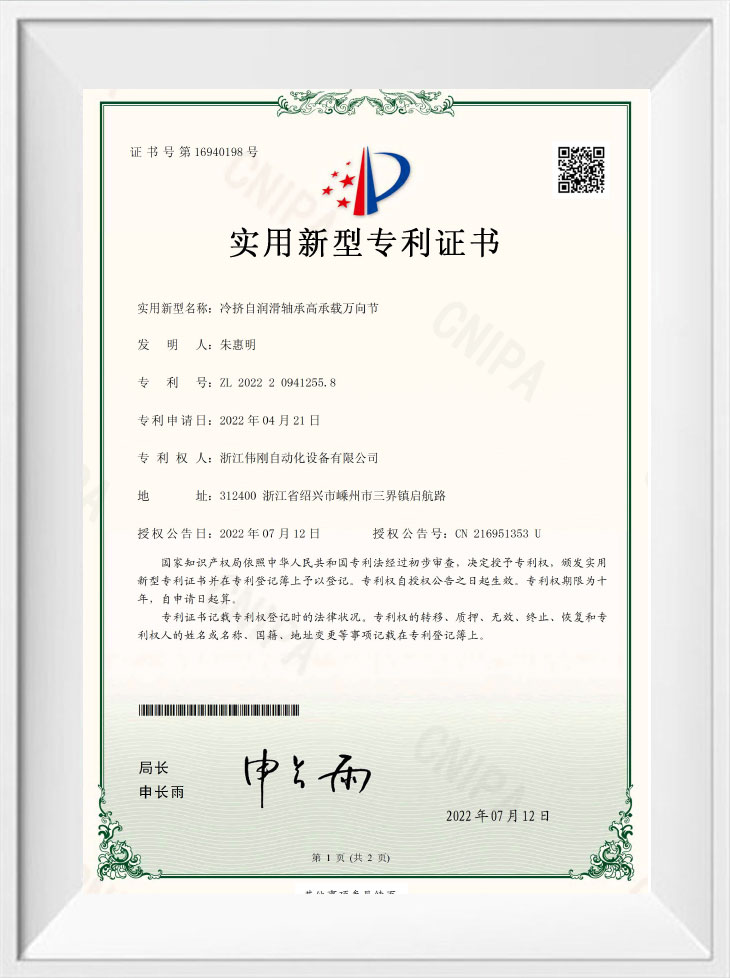

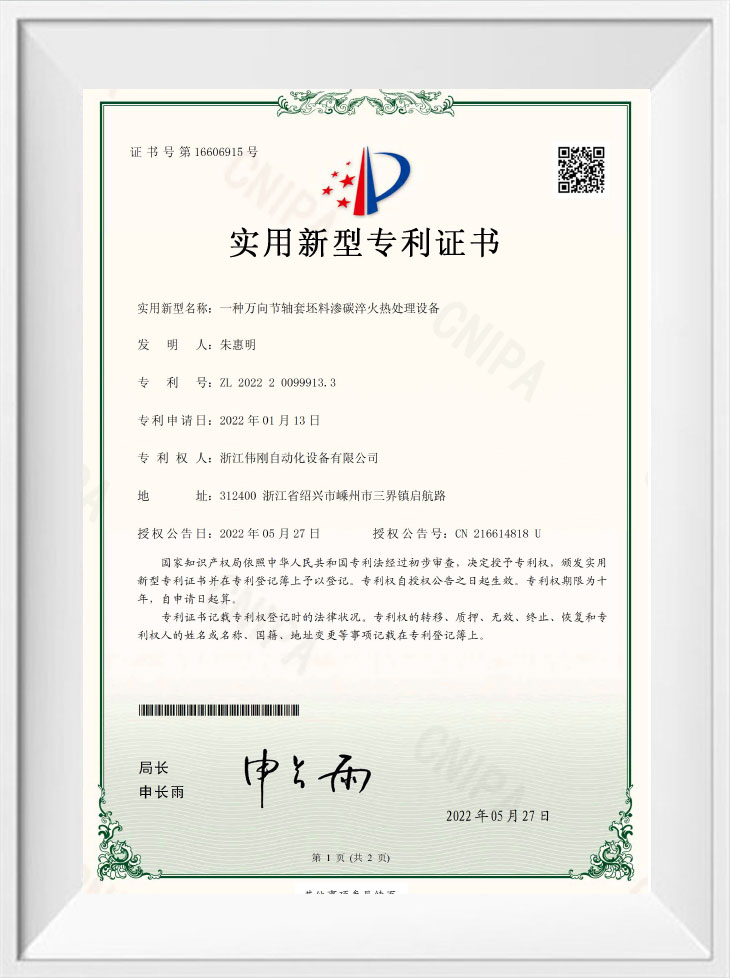

The high load-bearing capacity of Agricultural Machinery U-Joint is first attributed to its high-quality and reinforced material selection. These universal joints use high-strength and high-wear-resistant alloy steel or chrome steel as the base material. These materials have good mechanical properties and can maintain stable physical and chemical properties in harsh farmland working environments. Some high-end universal joints also use surface treatment technologies, such as carburizing and quenching, nitriding, etc., to further enhance the hardness and wear resistance of the material, thereby improving the overall load-bearing capacity.

2. Optimization of structural design

The structural design of Agricultural Machinery U-Joint is also one of the key factors for its high load-bearing capacity. In order to withstand the large torque and impact force generated by agricultural machinery during operation, the universal joint adopts a multi-fork or cross-axis structure, which can effectively disperse the load and reduce the occurrence of stress concentration. Designers will also perform precise size calculations and strength checks on the various components of the universal joint to ensure that every detail meets the requirements of high load-bearing capacity. Some advanced universal joints will also use special lubrication systems and sealing devices to reduce friction and wear and further improve the load-bearing capacity.

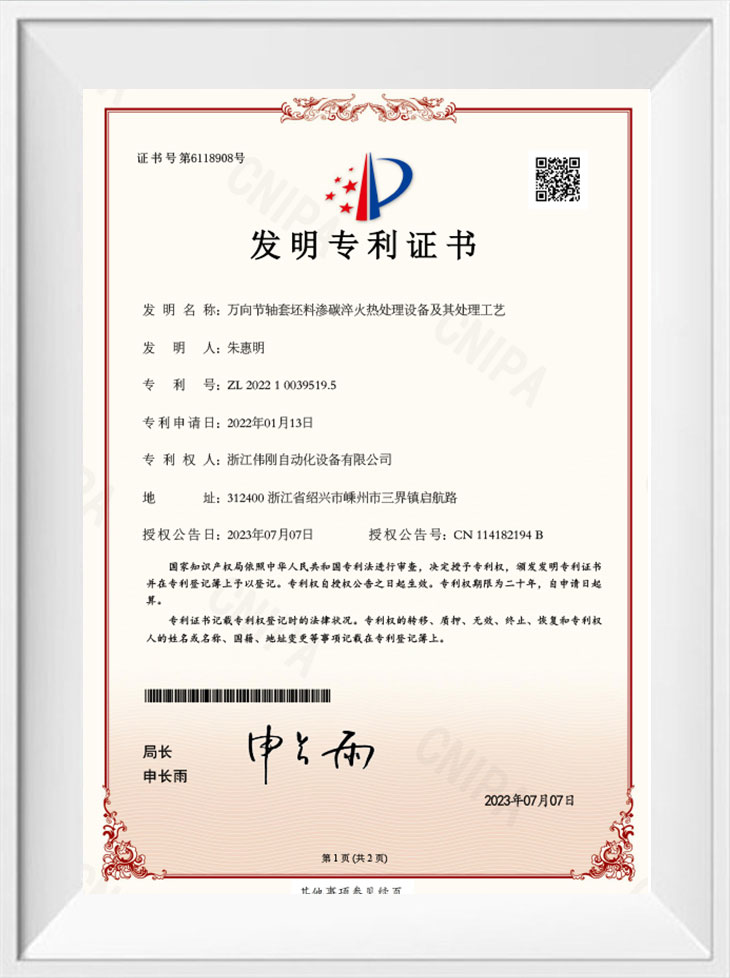

3. Exquisite manufacturing technology

Exquisite manufacturing technology is also a necessary condition for Agricultural Machinery U-Joint to achieve high load-bearing capacity. In the manufacturing process, every step needs to strictly follow the process flow and quality standards, from cutting and forging of raw materials to heat treatment, machining, and finally assembly and testing. Every link needs to be carefully operated and strictly controlled. In particular, the heat treatment process can improve its mechanical properties and load-bearing capacity by changing the microstructure of the material. In the manufacturing process, parameters such as heating temperature, insulation time and cooling rate must be strictly controlled to ensure that the universal joint reaches the best mechanical performance state.

4. Improvement of adaptability and durability

In order to meet the needs of agricultural machinery in complex and changeable farmland operation environments, the Agricultural Machinery U-Joint also fully considers adaptability and durability in design. The flexible design is adopted in the connection part to allow a certain angle deviation and axial displacement between the shafts, thereby ensuring the continuity and stability of power transmission. By optimizing the design of the lubrication system and sealing device, friction and wear can be reduced and the service life of the universal joint can be extended. Some high-end universal joints also have an automatic self-aligning function, which can automatically adjust the relative position between the shafts and reduce the additional load and stress concentration caused by installation errors or vibrations.

Application of Agricultural Machinery U-Joint

1. Connect the source of power and ensure smooth transmission

The core function of Agricultural Machinery U-Joint is to connect different shafts or components, allowing them to rotate relative to each other within a limited angle range while transmitting torque and power. In large agricultural machinery such as tractors, harvesters, and rice transplanters, the power generated by the engine needs to be transmitted to various working parts such as wheels, blades, and rollers through the transmission system. In this process, U-Joint plays this important role. It can not only ensure the continuity and stability of power transmission, but also adapt to various angle changes of agricultural machinery in complex terrain and working environment, ensuring the smooth operation of the transmission system.

2. Improve work efficiency and enhance mechanical performance

Agricultural Machinery U-Joint has the characteristics of flexibility and high load-bearing capacity. It can effectively reduce energy loss and mechanical wear during transmission and improve the working efficiency of agricultural machinery. When working in the field, agricultural machinery needs to frequently adjust its direction and angle to adapt to different operating requirements. The flexible connection characteristics of U-Joint make this adjustment easy and convenient without additional power or time consumption. Its high load-bearing capacity design also ensures that agricultural machinery can maintain stable performance when overloaded or running at high speed.

3. Adapt to various environments and meet diverse needs

The agricultural production environment is complex and changeable. From flat cultivated land to rugged mountains, from wet paddy fields to dry dry land, different operating environments have different requirements for agricultural machinery. The wide adaptability and diversified design of Agricultural Machinery U-Joint meet these different needs. Whether it is connecting the engine and the transmission system or connecting the power transmission between various working parts, U-Joint can provide a reliable and stable connection solution. For specific operating environments and operating requirements, special U-Joints can also be customized to meet special transmission requirements.

4. Ensure safe operation and reduce maintenance costs

During the operation of agricultural machinery, safety is always the first priority. The reliable connection and stable transmission of Agricultural Machinery U-Joint ensure the efficient operation of agricultural machinery and the safety of operators. Due to its reasonable structural design, excellent material and exquisite manufacturing process, U-Joint has high durability and wear resistance, which can reduce downtime and maintenance costs caused by failure or damage. Some advanced U-Joints are also equipped with maintenance auxiliary systems such as automatic lubrication and sealing devices, which further reduce the difficulty and cost of maintenance.

5. Promote agricultural modernization and help rural revitalization

As an important part of the agricultural mechanization process, the wide application of Agricultural Machinery U-Joint has not only improved agricultural production efficiency and quality level, but also promoted the process of agricultural modernization. With the continuous advancement of science and technology and the continuous improvement of agricultural mechanization, Agricultural Machinery U-Joint will continue to play its important role and continue to innovate and develop to adapt to new needs and challenges. It will also provide strong support for the implementation of the rural revitalization strategy and help achieve the goal of sustainable development of agriculture.

English

English 中文简体

中文简体