Why is the stability of Back Groove Round Bearings U-Joint so high?

1. Precision manufacturing and high-quality materials

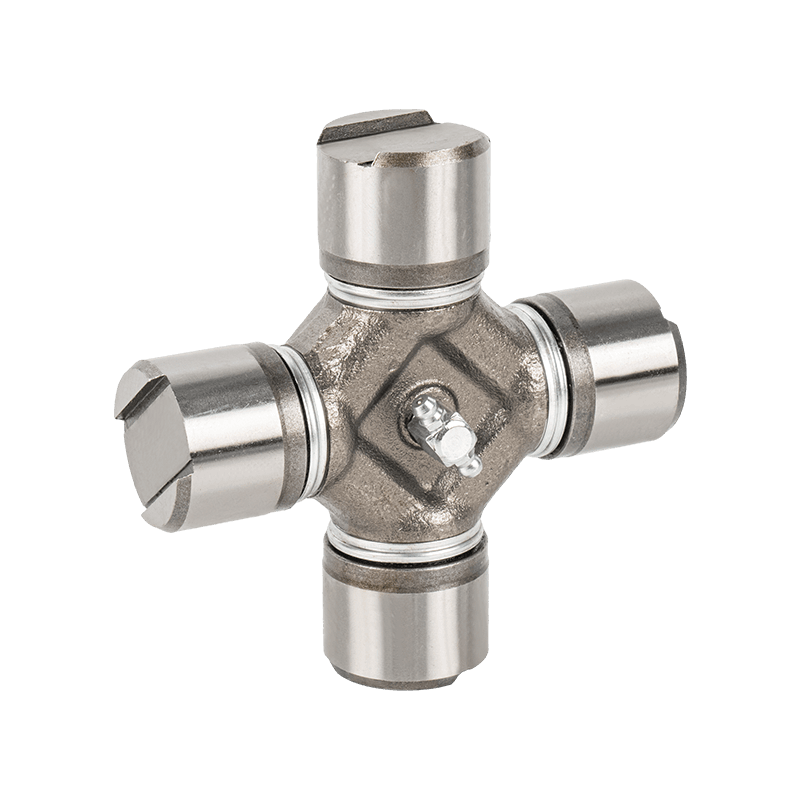

The stability of Back Groove Round Bearings U-Joint is due to its precise manufacturing process and high-quality material selection. As its core component, round bearings are usually made of high-strength and high-wear-resistant alloy materials, such as stainless steel and chrome steel. These materials will undergo strict quality control and precision processing to ensure the smoothness and precision of the bearing surface, thereby reducing friction and wear during rotation and improving overall stability and durability. The universal joint part also uses advanced manufacturing technology and high-quality materials to ensure its flexibility and reliability under complex working conditions. Through precise assembly and debugging, the cooperation between the universal joint and the bearing has achieved extremely high precision, further improving the stability of the entire component.

2. Unique structural design

The unique structural design of Back Groove Round Bearings U-Joint is also an important guarantee for its high stability. The design of the round bearing itself has excellent load-bearing capacity and rotational stability. The raceway between its inner and outer rings is reasonably designed, and the rolling elements can evenly distribute and bear the load, effectively avoiding the problems of stress concentration and local wear. The design of the universal joint allows the connection parts to be adjusted in multiple directions without worrying about interruption or instability of power transmission. This flexibility not only improves the adaptability of mechanical equipment, but also further enhances the stability of the bearing assembly by dispersing loads and reducing impact.

3. Clever application of back groove design

The back groove design is a highlight of the Back Groove Round Bearings U-Joint and one of the key factors for its high stability. The presence of the back groove provides additional support and fixing points for the bearing assembly, which helps to reduce displacement and shaking caused by vibration or impact. The back groove can also be used as an installation location for seals to prevent impurities such as dust and moisture from entering the bearing, maintaining its good working environment and performance. The customized design of the back groove also provides more flexible options for different application scenarios. Users can customize the shape, size and position of the back groove according to actual needs to achieve precise matching with other components and special functional requirements. This flexibility not only improves the practicality of the bearing assembly, but also further enhances its overall stability.

4. Strict quality control and testing

The high stability of the Back Groove Round Bearings U-Joint is also inseparable from strict quality control and testing. During the production process, every link follows strict quality standards and process requirements to ensure the best quality and performance of the product. The product also needs to undergo multiple tests and inspections, including rotation performance test, load capacity test, sealing performance test, etc., to ensure that it can show excellent stability in actual applications.

What are the specific features of Back Groove Round Bearings U-Joint?

1. Excellent load-bearing capacity

Back Groove Round Bearings U-Joint has excellent load-bearing capacity due to its high-strength materials and precise manufacturing process. The round bearing part is made of high-quality alloy materials, and is precision heat treated and surface processed to ensure its high hardness and wear resistance. This material selection and processing method enables the bearing to maintain a stable operating state under heavy load conditions and is not prone to deformation or damage. The design of the universal joint allows the connection parts to be adjusted in multiple directions, further dispersing the load and improving the overall load-bearing capacity.

2. Flexible angle adjustment

Another major feature of Back Groove Round Bearings U-Joint is its flexible angle adjustment capability. The universal joint part adopts a special structural design, which allows the connection parts to rotate freely within a certain range without worrying about angle restrictions or power transmission interruptions. This flexibility greatly improves the adaptability and reliability of mechanical equipment, allowing the equipment to maintain a stable operating state in a complex and changing working environment. The flexibility of angle adjustment also facilitates the installation and maintenance of the equipment, reducing the difficulty and cost of operation.

3. Unique back groove design

The back groove design of Back Groove Round Bearings U-Joint is a highlight of its functional features. The existence of the back groove not only provides additional support and fixing points for the bearing assembly, enhances the overall stability, but also provides the possibility for installation, sealing or special cooperation with other components. The back groove can be customized according to specific needs to meet the specific requirements of different application scenarios. This design not only improves the practicality of the bearing assembly, but also provides a strong guarantee for its stable operation under specific working conditions.

4. Precision manufacturing process

The manufacturing process of Back Groove Round Bearings U-Joint is also commendable. During the production process, every link follows strict quality standards and process requirements to ensure the best quality and performance of the product. From material selection, processing to assembly and commissioning, every link is carefully designed and strictly controlled to ensure the accuracy and stability of the bearing assembly. This precision manufacturing process not only improves the performance of the product, but also extends its service life and reduces the user's maintenance cost.

5. Wide range of application fields

Due to its excellent functional characteristics, Back Groove Round Bearings U-Joint has been widely used in many fields. In the automotive industry, it is widely used in transmission systems, suspension systems and power output devices, ensuring the stable operation of vehicles under various road conditions; in the field of engineering machinery, it undertakes the important task of transmitting large torque and bearing heavy loads, providing stable power support for heavy equipment such as excavators and loaders; in the aerospace field, it provides strong guarantees for the safe flight and precise control of aircraft with its high precision and high reliability, and it also plays an important role in precision machine tools, automation equipment, industrial robots and other fields.

English

English 中文简体

中文简体