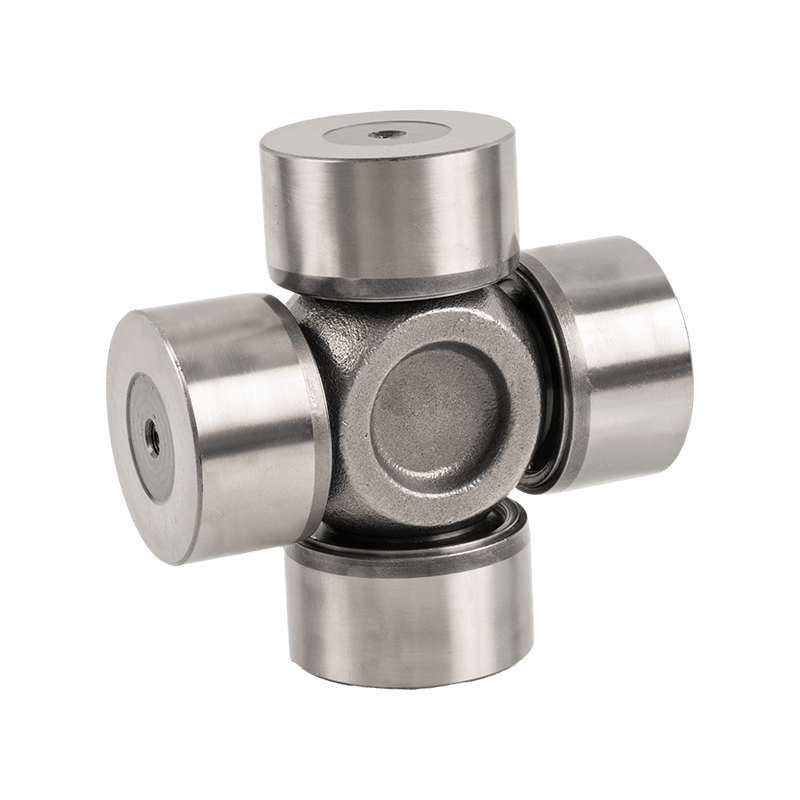

What are the application scenarios of Industrial Equipment Cross Kits?

1. In aerospace, an industry with extremely high requirements for precision and safety, Industrial Equipment Cross Kits have demonstrated its unique value. From regular inspections of aircraft engines to meticulous maintenance of airframe structures, these kits provide comprehensive support including high-precision measurement tools, specialized disassembly and assembly tools, and material-specific spare parts. Equipment Cross Kits help technicians quickly locate and solve problems. potential problems to ensure that every aircraft can fly in the sky in the best condition and protect the safety of passengers and crew.

2. Automobile manufacturing is a highly automated industry with complex processes. From stamping, welding to final assembly, every link is inseparable from the support of industrial equipment. The application of Industrial Equipment Cross Kits in the field of automobile manufacturing is mainly reflected in rapid mold change, equipment debugging and maintenance on the production line. By providing standardized tool sets and easily replaceable spare parts, these kits significantly reduce equipment downtime and increase productivity. At the same time, professional testing tools can also ensure the accuracy and quality of each component, providing a solid guarantee for the overall performance and safety of the car.

3. Mechanical processing is one of the core links in the manufacturing industry, involving various processes such as milling, turning, and grinding. In this process, Industrial Equipment Cross Kits provide mechanical processing companies with solutions that can flexibly respond to various processing needs. Whether adjusting machine parameters, replacing tools or repairing worn parts, these kits provide the necessary tools and spare parts. For high-precision processing tasks, the high-precision measurement tools and calibration equipment in the kit can also help technicians achieve micron-level processing accuracy control to ensure the stability and improvement of product quality.

4. In the field of energy and power, Industrial Equipment Cross Kits also play an important role. From boiler maintenance in thermal power plants to blade maintenance in wind farms, these kits provide a strong guarantee for the stable operation of energy facilities, especially in the context of the current global energy transformation, new energy equipment such as solar photovoltaic panels, energy storage The installation and maintenance of batteries are also inseparable from the support of these kits. They not only improve maintenance efficiency and safety, but also promote the rapid development and popularization of green energy technology.

5. The petrochemical industry is one of the pillar industries of the national economy. Its production process has the characteristics of high temperature, high pressure, flammability and explosion. In such an environment, Industrial Equipment Cross Kits has won wide recognition for its professionalism and safety. From pipeline valve repairs to regular inspection and maintenance of refining equipment, these kits provide comprehensive tool and spare parts support. In response to the special needs of the petrochemical industry, the explosion-proof tools and safety protection equipment in the kit can also effectively protect the life safety and health of workers.

Industrial Equipment Cross Kits use their comprehensive, convenient and customized features to play an important role in multiple industrial scenarios such as aerospace, automobile manufacturing, machining, energy and power, and petrochemical industry. They not only improve production efficiency and product quality, but also promote the innovation and development of industrial technology. With the advent of the Industry 4.0 era and the rise of intelligent manufacturing, the application prospects of Industrial Equipment Cross Kits will be even broader, injecting an injection into the development of modern industry. New vitality and momentum.

Why are Industrial Equipment Cross Kits safe and reliable?

1. Professional design ensures precise operation

The safety and reliability of Industrial Equipment Cross Kits are first of all due to its professional and sophisticated design. These kits are usually carefully designed by experienced engineers and technical experts according to the actual needs of industrial equipment to ensure that every tool and every spare part can accurately match the maintenance needs of the equipment. From high-precision measuring tools to special disassembly and assembly tools, from precision calibration equipment to quick replacement systems, every link has been strictly tested and verified to ensure that various tasks can be completed accurately during use, thereby avoiding safety accidents caused by tool mismatch or improper operation.

2. Strict quality control to ensure product quality

Quality is the cornerstone of the safety and reliability of industrial equipment cross kits. In order to ensure that every product in the kit can meet the highest standards, manufacturers usually adopt a strict quality control system, from raw material procurement, production and processing to finished product inspection, every link is strictly controlled. By adopting advanced production processes and testing equipment, manufacturers can ensure that the tools, spare parts and other products in the kit meet the relevant standards and requirements in terms of material, size, precision, etc. Regular quality audits and continuous improvement mechanisms also ensure the continuous improvement and stability of the kit quality.

3. Easy to operate and reduce human errors

Human error is one of the common causes of industrial accidents. In order to reduce this risk, Industrial Equipment Cross Kits are designed with ease of use and simplicity of operation in mind. By adopting ergonomic design, optimizing operating procedures, and providing clear instructions, these kits can help operators master the use of tools more quickly and reduce errors and accidents caused by improper operation. Some advanced kits may also be equipped with intelligent auxiliary systems, such as automatic detection and fault diagnosis, to further improve the safety and efficiency of operations.

4. Continuous support to ensure long-term safety

In addition to the above measures, Industrial Equipment Cross Kits also provides continuous technical support and after-sales service guarantees. Manufacturers usually set up professional technical support teams and after-sales service networks to provide users with a full range of service support such as technical consultation, troubleshooting, and spare parts replacement. This continuous support mechanism can ensure that the kits are always in the best condition during use, thereby ensuring the long-term safe and stable operation of industrial equipment.

Industrial Equipment Cross Kits have become an important and safe tool for the maintenance and upgrade of industrial equipment due to their professional design, strict quality control, comprehensive protection, easy operation and continuous support. They not only improve production efficiency and product quality, but also provide a solid guarantee for the safe production of industrial enterprises.

English

English 中文简体

中文简体