From mechanical transmission to agricultural applications, the importance of U-joint in PTO drive shaft

Content

In modern agricultural machinery, the power transmission system is the core of the efficient operation of the equipment, and the PTO drive shaft is an important channel for transmitting engine power to various working parts. As a key connecting component in the PTO drive shaft, the role of U-joint is indispensable. It not only ensures the efficient transmission of power, but also plays a role in ensuring stability and durability in the long-term operation of agricultural machinery.

Basic concepts and functions of U-joint

Definition and working principle of U-joint

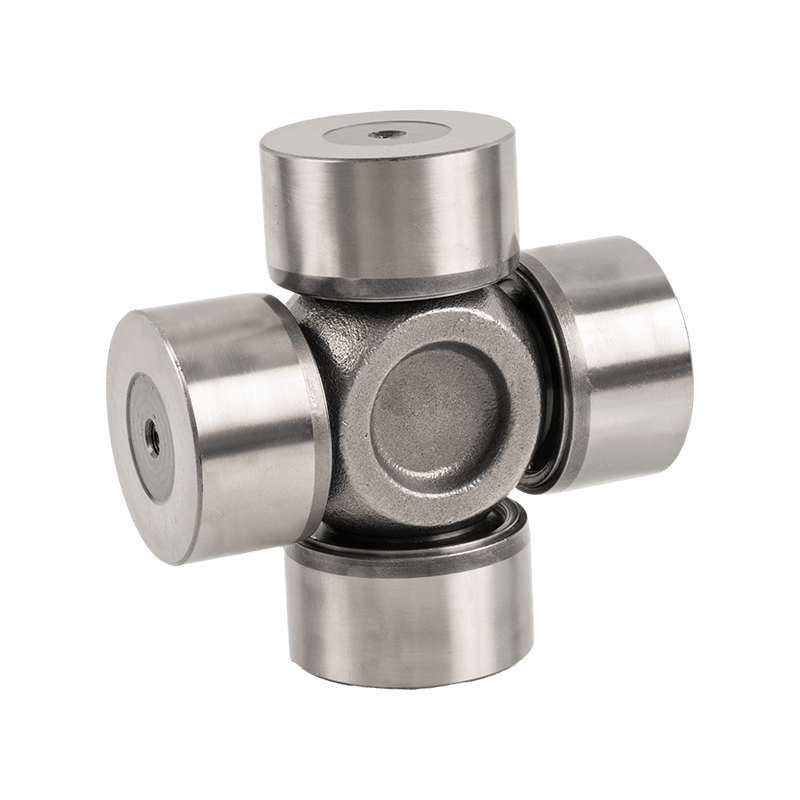

U-joint is a mechanical connection component used to connect various parts of the power system. It can transmit the rotational power generated by the engine through the PTO drive shaft to the working parts of agricultural equipment. It can adapt to the changes in the angle of the drive shaft through the universal structure design, so that the power can be stably transmitted to each working part, ensuring that the equipment can still operate efficiently under different angles and complex working conditions.

The core advantage of U-joint lies in its flexibility and adaptability. Agricultural machinery usually needs to work on uneven ground. The universal design of U-joint allows it to adapt to different working angles to avoid power loss or equipment failure caused by angle deviation.

Working characteristics of U-joint

The universal design of U-joint ensures that power can be transmitted seamlessly during the operation of agricultural machinery. It can adapt to different working conditions, whether it is straight-line operation or operation with large angle deviation. At the same time, the sturdy structure of U-joint can withstand vibration and impact in agricultural operations, reducing damage or wear caused by uneven ground or equipment vibration. High-quality U-joint not only improves the durability of equipment, but also enhances the stability of power transmission, thereby ensuring the efficient development of agricultural operations.

Application of U-joint in agricultural machinery

Key role of power transmission

The application of U-joint in agricultural machinery is mainly reflected in the power transmission process. It transmits the power generated by the engine through the PTO drive shaft to various working parts of the agricultural machinery. The operation of agricultural machinery requires strong power support. Whether it is the tillage operation of the tractor or the harvesting operation of the harvester, the U-joint ensures that the power can be quickly and stably transmitted to the working parts of the equipment, thereby ensuring the smooth progress of the operation.

For example, the tractor transmits the power generated by the engine to the tillage knife or sowing device through the U-joint to ensure the efficiency of the land tillage or sowing process. In the application of the harvester, the U-joint also transmits power to the header, so that the crops can be cut accurately. And this efficient power transmission is inseparable from the cooperation of the U-joint.

Improvement of efficient operation and energy saving effect

As the requirements for efficiency in agricultural production become higher and higher, the design of the U-joint is also being optimized to improve the operation efficiency. An efficient U-joint can reduce the energy loss in the power transmission process, ensure that the rotational power of the engine can be fully utilized, and avoid power waste. Especially in some larger or more complex agricultural machinery, the optimized design of the U-joint can help the mechanical equipment maintain stable operating efficiency under different working conditions and improve the production capacity of the overall equipment.

In addition, as energy consumption and environmental protection become global hotspots, the role of U-joint in energy saving is becoming increasingly important. Through efficient power transmission, U-joint can effectively reduce the loss of mechanical energy, thereby reducing fuel consumption. For agricultural producers, this can not only reduce costs, but also reduce environmental pollution, which meets the requirements of modern agriculture for energy conservation and emission reduction.

Coping with harsh working environments

The working environment of agricultural machinery is usually very complex, especially when working in the field, the equipment may need to deal with uneven ground, slippery soil or stone-filled environments. In this case, the equipment often needs to withstand a lot of vibration and impact. U-joint can effectively reduce the impact of these external factors on the equipment with its anti-seismic and anti-impact design.

The universal design of U-joint enables it to adapt to changes in different angles and avoid angular deviation of the drive shaft due to uneven ground. At the same time, its durability enables it to resist the impact from uneven ground during continuous operation, reduce the failure rate of mechanical equipment in complex environments, and thus ensure the continuity and stability of agricultural operations.

Improve the stability and safety of machinery

The stability and safety of agricultural machinery are the basis for improving operating efficiency. U-joint, through its structural design, can ensure that agricultural equipment will not cause transmission system failure due to loose or damaged joints during operation. Especially under high-load operation, U-joint enhances the pressure resistance of machinery through optimized wear-resistant materials and high-strength design, avoiding equipment damage caused by excessive pressure.

In the agricultural production process, mechanical failure will not only stop work, but may also bring more serious safety hazards. The high safety and stability of U-joint can effectively avoid safety accidents caused by joint breakage or detachment, and protect the safety of operators and equipment. Therefore, choosing a high-quality U-joint can fundamentally improve the safety and working stability of agricultural machinery.

Reduce repair and maintenance costs

The efficient operation of agricultural machinery is inseparable from the good condition of the equipment, and the high durability and stability of U-joint can reduce the repair and maintenance work caused by failures. In the long-term use of agricultural machinery, the U-joint bears a large load. If the design and manufacturing quality are not up to standard, it is easy for the joint to loosen, wear or break, which will affect the normal operation of the equipment. By choosing a high-quality U-joint, the occurrence of these problems can be significantly reduced, thereby reducing the maintenance frequency and related costs of the machinery.

Technological evolution and future trends of U-joint

Innovation of materials and processes

With the development of agricultural machinery, the materials and manufacturing processes of U-joints are also constantly innovating. Traditional U-joints are mostly made of high-strength steel, which has good compression resistance and wear resistance. However, with the diversification of working environments and the increase in demand, modern U-joints have begun to use composite materials or more advanced alloy materials. These new materials not only improve the strength of the joints, but also have significantly improved corrosion resistance and aging resistance, allowing U-joints to better cope with various harsh environments in agricultural operations.

Intelligence and remote monitoring

In the future, with the continuous advancement of agricultural intelligence, the functions of U-joints will be further expanded. Smart agriculture will increasingly rely on high-precision equipment and sensor technology. U-joints may also integrate smart sensors to monitor the working status, temperature, pressure and other important parameters of the joints in real time. These data will be transmitted to the agricultural management system via wireless networks to provide real-time fault warnings and maintenance suggestions, thereby achieving accurate predictive maintenance.

The application of intelligent U-joints can reduce human intervention and improve the working efficiency of agricultural machinery. At the same time, it will further improve the safety and stability of equipment and promote agricultural production towards intelligence and automation.

English

English 中文简体

中文简体