How to maintain the Tractor Universal Joint to reduce the failure rate

Content

- 1 Understand the working principle and common faults of the tractor universal joint

- 2 Regular cleaning and inspection to prevent external contaminants from intruding

- 3 Regularly change lubricants to avoid insufficient lubrication

- 4 Check the oil seals and seals regularly to prevent leakage and contamination

- 5 Avoid overloading and high-frequency use to reduce excessive load

- 6 Regular professional inspection and maintenance

As one of the core components of agricultural machinery, the tractor universal joint is a key device for transmitting power and ensuring the stable operation of agricultural machinery. Whether it is plowing, sowing, harvesting, or other agricultural activities, the universal joint plays a vital role. However, the tractor universal joint often faces problems such as wear and corrosion in a long-term high-load working environment. In order to ensure the efficiency and reliability of the tractor at work, understanding the working principle and common faults of the universal joint and performing scientific maintenance are necessary measures to reduce the failure rate and increase the service life of the tractor.

Understand the working principle and common faults of the tractor universal joint

The tractor universal joint is a key component in the power transmission system. Its main function is to transmit the power output of the engine to other working devices of the tractor. In agricultural machinery, since tractors often need to work at different angles and loads, the design of the universal joint enables it to maintain the stability of power transmission at different axis angles, thereby ensuring that the tractor can still operate smoothly and efficiently in complex working environments.

Working Principle

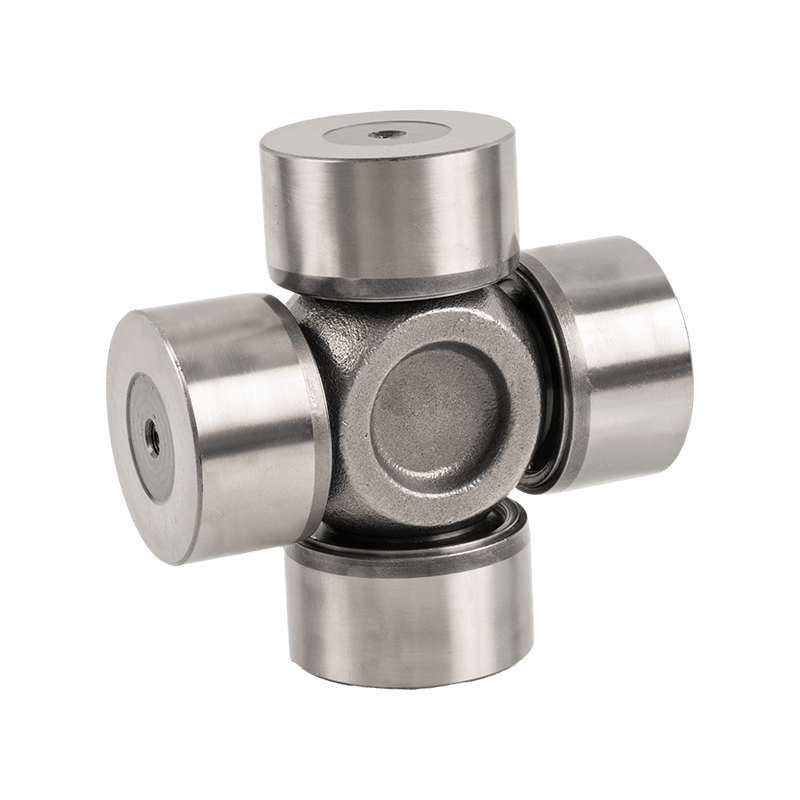

The tractor universal joint consists of a cross shaft, a pin shaft, a needle bearing, an oil seal and other parts. Its basic working principle is to transmit the rotational power of the drive shaft to other parts of the tractor through the rotation of the cross shaft. The universal joint allows the drive shaft to rotate freely within a certain angle to adapt to complex agricultural operation scenarios, such as pressure changes in different terrains when plowing, or frequent changes in rotation angles during harvesting operations.

Since tractors often face violent rotations, impacts and load fluctuations when working, the design of the universal joint must be able to adapt to these changing working environments. At this time, the internal needle bearings and pin shafts of the universal joint play a role in reducing friction and maintaining smooth transmission. The oil seal plays the role of retaining lubricating oil, preventing dirt and moisture from entering, and protecting the internal parts from the external environment.

Common faults

Common faults of tractor universal joint are mainly as follows:

Excessive wear: Long-term high-load use, especially in the case of improper operation or frequent operation, the needle rollers, cross shafts and other parts inside the universal joint are prone to excessive wear, resulting in poor power transmission and reduced work efficiency.

Oil seal failure: The oil seal of the universal joint is responsible for preventing dirt and moisture from entering the internal parts. If the oil seal is aged, cracked or damaged, it will cause lubricating oil leakage, thereby aggravating wear and even causing rust or jamming of the metal surface.

Loose or falling off: If the bolts of the universal joint connection parts are loose, it may cause the universal joint connection to be unstable, or even cause transmission breakage or falling off, which may cause the agricultural machinery to stop in severe cases.

Corrosion and rust: When exposed to corrosive environments such as moisture and salt, the metal parts of the universal joint are easily corroded, resulting in component failure and affecting its normal operation.

Understanding the common causes of these faults can help users to be targeted and deal with them in a timely manner during maintenance to avoid the expansion of faults and affect the operating efficiency of the tractor.

Regular cleaning and inspection to prevent external contaminants from intruding

The tractor universal joint is often exposed to harsh working environments such as mud, dust, and moisture. Long-term accumulation of dirt may accelerate the wear of the universal joint and cause failures. Therefore, it is important to clean the universal joint regularly and inspect it to ensure its internal and external cleanliness.

Cleaning method:

External cleaning: After each operation, especially when the working environment is wet or muddy, the surface dirt and impurities of the universal joint must be washed away with a water gun or high-pressure air. Especially when harvesting or fertilizing, dirt and pesticide residues are easily attached to the parts of the universal joint, so they must be cleaned in time.

Lubricant inspection: Check the condition of the universal joint oil seal and lubricant. If the lubricant is seriously contaminated or has lost its lubricating effect, it must be replaced immediately.

Regular cleaning can effectively prevent dirt from corroding the universal joint, reduce wear, and extend the service life of the universal joint.

Regularly change lubricants to avoid insufficient lubrication

Lubricants are the core of the efficient operation of universal joints. Lack of lubrication will cause excessive friction between parts, and even cause jamming or wear. Regularly changing lubricants can not only ensure the smooth operation of universal joints, but also reduce the probability of failure.

Tips for changing lubricants:

Lubricant selection: Select suitable lubricants according to the use environment and operating conditions of the tractor. For high temperature, low temperature or various working environments, high-performance lubricants that meet the standards should be used.

Check the oil level and oil quality: Check the oil level of the lubricant regularly and make sure that the lubricant has not deteriorated. If the oil is found to be dirty or viscous, it means that the lubricant has lost its effect and needs to be replaced in time.

The replacement cycle of lubricants is usually between 250 and 300 hours, which should be adjusted according to the frequency of use of the tractor and the working environment.

Check the oil seals and seals regularly to prevent leakage and contamination

Oil seals and seals are key components to prevent lubricating oil leakage and external contaminants from entering the universal joint. If the oil seal is damaged, dirt and moisture will enter the universal joint, accelerating its wear and corrosion, so it is very important to check the integrity of the oil seal regularly.

Inspection method:

Check the integrity of the oil seal: Check the aging of the oil seal during each maintenance. If cracks or aging are found, replace it as soon as possible.

Prevent external contaminants from entering: Avoid exposing the universal joint to dust or muddy water, especially when spraying pesticides or fertilizers, which is common in agricultural production, special attention should be paid to seal protection.

By replacing aging oil seals in time, lubricating oil leakage and external contaminants can be avoided, and the internal structure of the universal joint can be protected.

Avoid overloading and high-frequency use to reduce excessive load

When the tractor is operating, especially when performing heavy load operations, the universal joint bears tremendous pressure. Long-term overload or frequent operation may cause the universal joint components to overload, thereby accelerating their wear.

Measures to prevent overload:

Reasonable arrangement of work tasks: Avoid keeping the tractor in a high-load working state for a long time, and arrange the work load reasonably according to the actual needs of the work.

Check the load: Check whether the tractor's working load matches the design standard to ensure that it works within the safe load range.

Reasonable control of the tractor's load and avoid overload operation can not only improve the tractor's working efficiency, but also effectively reduce the failure rate of the universal joint.

Regular professional inspection and maintenance

Although daily maintenance can effectively extend the service life of the universal joint, professional inspection and maintenance should not be ignored. By regularly sending the tractor to a professional repair station for a comprehensive inspection, potential problems can be discovered and solved in time to prevent small problems from developing into major failures.

Professional inspection content:

Check the degree of wear of the universal joint: Use professional equipment to detect the wear of the universal joint and determine whether it needs to be replaced.

Check key components such as bearings and pins: Ensure these components are in good working condition to avoid tractor downtime due to component failure.

Regular professional inspections can ensure that the tractor universal joint is always in good working condition.

English

English 中文简体

中文简体