Key Applications of Russia Cross Joint in the Oil and Gas Industry

Content

Against the backdrop of growing global energy demand, the oil and gas industry is increasingly in need of efficient and reliable pipeline connection technology. Especially in harsh working environments, traditional pipeline connection methods have been unable to meet the operating requirements under complex conditions such as high pressure, high temperature and corrosion. In recent years, Russia cross joint has rapidly become one of the key solutions for pipeline connection in the oil and gas industry with its technical performance.

Basic Concepts of Russia Cross Joint

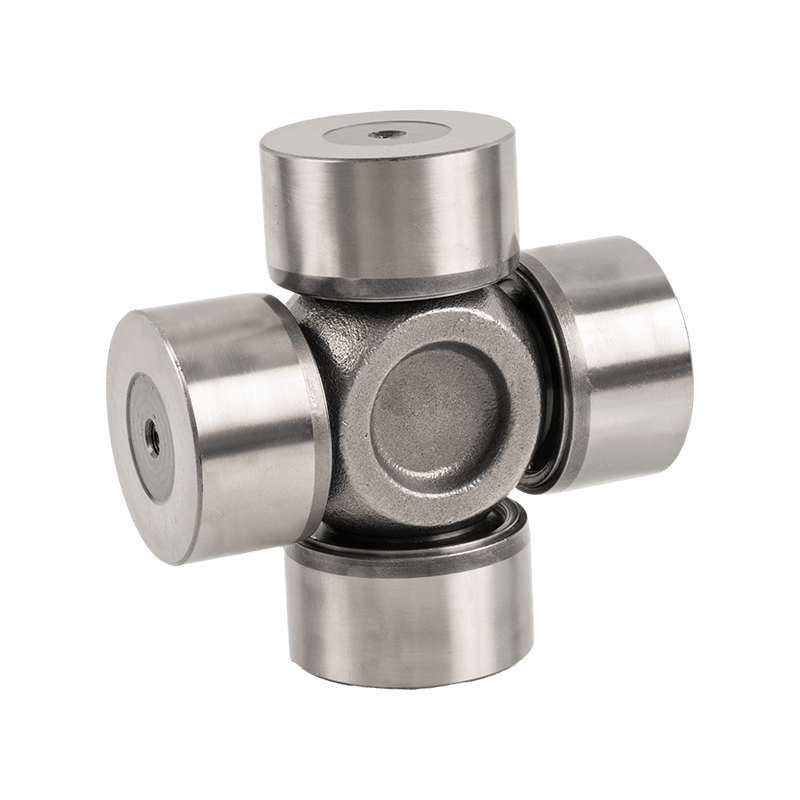

Russia cross joint is an innovative pipeline connection method that is widely used in oil and gas transportation systems. Its main feature is the cross structure design, which makes the pipeline connection more stable and can effectively withstand the challenges brought by harsh environments such as high pressure and high temperature. Unlike traditional welding and flange connection methods, Russia cross joint can evenly distribute pressure when subjected to pressure, avoiding local overload, thereby improving the overall strength and sealing of the joint.

Especially in the field of oil and gas, pipelines often need to operate in complex natural environments and high pressure conditions, which places very high requirements on the quality of pipeline connections. The design concept of the Russian cross joint is to meet these severe challenges and ensure the long-term stability and safety of the pipeline.

The importance of the Russian cross joint in the oil and gas industry

1. Meeting the challenges of high-pressure and high-temperature environments

The transportation system of oil and gas usually needs to pass through high-temperature and high-pressure environments. Especially in deep sea, extremely cold areas and crude oil and natural gas fields far away from cities, the working conditions faced by pipelines are particularly harsh. Traditional pipeline connection technology often faces problems of insufficient durability and poor sealing performance under these conditions, and is prone to serious accidents such as pipeline rupture and leakage, affecting the transportation safety of resources.

The Russia cross joint technology effectively solves this problem. Its cross design can evenly disperse the pressure in the pipe joint part and reduce the deformation or damage of the joint caused by local pressure concentration. Even in a high-pressure environment, the Russia cross joint can ensure the stability and safety of the pipeline connection. More importantly, this technology can still maintain good sealing and strength in high or low temperature environments, avoid gas or liquid leakage, and ensure the stable operation of the oil and gas transportation system.

2. Improve corrosion resistance and extend service life

Oil and gas pipelines are often exposed to extremely corrosive environments, especially in offshore oil and gas fields or humid climate conditions. The surface of the pipeline is easily corroded by salt water, chemicals and even biological attachments. For a long time, traditional pipeline connection technology has often failed to effectively prevent the invasion of these external corrosion sources, resulting in early failure and safety hazards of the pipeline system.

Russia cross joint technology uses advanced anti-corrosion materials and surface treatment technology, which can significantly improve the corrosion resistance of the pipeline joint part. Whether it is seawater, acidic gas or other corrosive substances, it is difficult to affect this joint, ensuring the long-term service life of the pipeline. Since the joint part can resist corrosion, it not only reduces the maintenance frequency, but also reduces the oil and gas leakage accidents caused by pipeline corrosion, and improves the safety and reliability of the entire pipeline system.

3. Simplify pipeline construction and maintenance and reduce costs

Oil and gas pipeline construction usually requires complex planning, construction and maintenance processes, especially some long-distance or cross-sea pipeline routes, the construction cost and time cost are very high. Traditional pipeline connection methods, such as welding or flange connection, often require a lot of manpower and equipment support, are difficult to construct, have a long maintenance cycle, and are costly to repair.

In contrast, the Russia cross joint makes the pipeline construction process more efficient with its modular and simple installation design. By pre-manufacturing and inspecting pipeline components, only quick assembly is required during on-site construction, which greatly shortens the construction cycle. In addition, the design of the cross joint makes the pipeline connection more stable and durable, reducing the subsequent maintenance work and costs. Through this efficient construction and low maintenance advantage, the Russia cross joint not only improves the economy of pipeline construction, but also reduces maintenance expenses in long-term operation.

4. Ensure the safety and reliability of pipeline transportation

The transportation of oil and natural gas is a high-risk industry. Any failure or leakage of the pipeline may cause serious environmental pollution, property loss and even casualties. Therefore, the safety and reliability of pipeline connection technology are crucial. Especially in large-scale oil and gas field projects, any unstable connection point may cause huge safety hazards.

With its extremely high sealing, pressure resistance, and corrosion resistance, the Russia cross joint can effectively prevent leakage or failure of pipeline joints. Even under strong external impact, the unique design of the cross joint can disperse the pressure and avoid excessive local pressure on the joint part. This not only improves the stability of the pipeline, but also effectively reduces the safety hazards caused by oil and gas leakage, and ensures the reliability of energy transportation.

Application cases of Russia cross joint

1. Deep-sea oil and gas exploitation

The development of deep-sea oil and gas fields is one of the key directions in the current global energy field. Due to the special environment of submarine oil and gas fields, pipeline construction faces extremely high technical difficulties. Russia cross joint has played a huge role in the construction of deep-sea oil and gas pipelines. Its pressure resistance and corrosion resistance enable the pipeline to operate stably in a high-pressure and high-temperature deep-sea environment, ensuring the safe transportation of energy.

2. Arctic oil and gas pipelines

In extremely cold areas, such as Russia's Arctic oil and gas fields, extremely low temperatures pose a severe test to the durability of pipelines. Traditional pipeline technology often fails to meet the requirements of efficiency and safety in these environments. The low-temperature resistance of Russia cross joint makes it an ideal choice for Arctic oil and gas transportation pipelines. Whether it is the physical changes caused by low temperature or the oppression of the cold environment on the pipeline, the Russia cross joint can maintain its stability and ensure the safety of pipeline connection.

3. Central Asian oil pipeline

The transportation of oil pipelines in Central Asia involves complex geological and climatic conditions, which puts high demands on pipeline connection technology. Russia cross joints have been widely used in such pipeline systems, especially in high pressure, low temperature and corrosive environments. The cross joint technology effectively extends the service life of the pipeline and reduces maintenance costs.

English

English 中文简体

中文简体