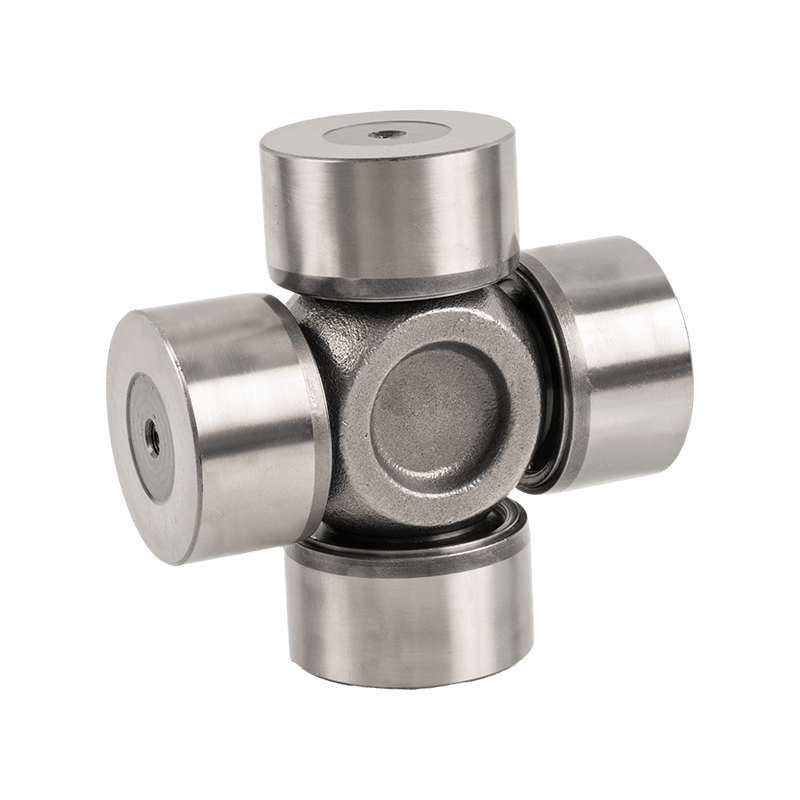

Upgrading of core parts for commercial vehicles: Volvo Scania Benz Cross Joint demand surges

With the continuous growth and technological upgrading of the global commercial vehicle market, Cross Joint, as a key component in the transmission system, has ushered in huge market attention and demand growth. Especially in high-end heavy-duty truck brands such as Volvo, Scania and Benz, the importance of Cross Joint has been continuously highlighted. The surge in demand is driven by multiple deep-seated factors, which is triggering an industry revolution in parts upgrade.

Multiple factors drive surge in demand: the core driving force of industry change

The rapid growth in demand for cross shafts is not accidental, but is driven by the powerful combined force of multiple industry trends and market demands. Only by fully understanding these driving forces can we grasp the pulse of industry development and plan the future market in advance.

1. Durability demand brought by improved transportation intensity

With the increasing logistics efficiency and transportation tasks, the use intensity of commercial vehicles continues to rise. The long-distance, high-load, and high-frequency operating environment makes the cross shaft subject to greater torque and more complex stress. Traditional standard parts are difficult to meet these conditions, driving the industry to upgrade to Cross Joint products with higher strength and longer life.

2. Replacement demand brought by the improvement of vehicle maintenance awareness

The top priority of commercial vehicle operating costs lies in maintenance and care. Operating companies are paying more and more attention to the preventive replacement of parts to avoid high failure losses. At the same time, old heavy trucks over 5 years old in Europe, the United States and emerging markets have entered the peak period of maintenance and repair. As a key part that is vulnerable to damage, the replacement demand for cross shafts has risen sharply, prompting the active after-sales market.

3. Quality improvement strategy of vehicle manufacturers

High-end commercial vehicle brands represented by Volvo, Scania, and Benz are promoting the performance upgrade and consistency improvement of supporting parts through strict parts certification and supply chain management. Cross Joint with high reliability and low failure rate has become an important support for vehicle quality assurance, which also makes these brands put forward higher technical thresholds for cross shaft suppliers, driving the overall upgrade of the industry.

4. The rise of smart manufacturing and monitoring needs

The development of Internet of Vehicles and intelligent operation and maintenance technology has put forward new requirements for real-time monitoring and fault warning of parts. Some high-end Cross Joints have begun to integrate status monitoring functions to help fleets achieve intelligent maintenance, further stimulating the market demand for intelligent cross shafts.

5. Green transportation policies and energy efficiency standards improvement

Global green logistics policies promote vehicle lightweighting and energy conservation and emission reduction, and energy consumption control in the transmission system has become a key technical research focus. By optimizing the structural design and material application of Cross Joint, it can not only improve transmission efficiency, but also effectively reduce the energy consumption of the entire vehicle, becoming a key part for manufacturers to pursue environmental protection goals.

Technological innovation helps demand explosion

Faced with the above multiple driving factors, Cross Joint technology is also constantly improving. A series of technological breakthroughs such as high-strength alloy steel materials, precision heat treatment processes, self-lubricating design, multiple sealing structures and intelligent detection interfaces have greatly improved the service life and reliability of the cross shaft. In particular, the research and development of special models for brands such as Volvo, Scania, and Benz meets the demanding working conditions.

Domestic manufacturers are catching up quickly in technology and quality, and are now able to provide products comparable to imported parts, gaining international market recognition and becoming a dual growth engine for exports and substitution.

English

English 中文简体

中文简体