Exploring the Role of U-Joints with 4 Grooved Bearings in Automotive Drivetrains

Content

In the world of automotive engineering, the efficiency and reliability of a vehicle's drivetrain are critical to its overall performance. Among the many components that contribute to a well-functioning drivetrain, the U-joint with 4 grooved bearings plays an essential role. This component, while often overlooked by everyday car owners, is vital in ensuring smooth power transfer between the engine and the wheels, especially in rear-wheel and all-wheel drive vehicles.

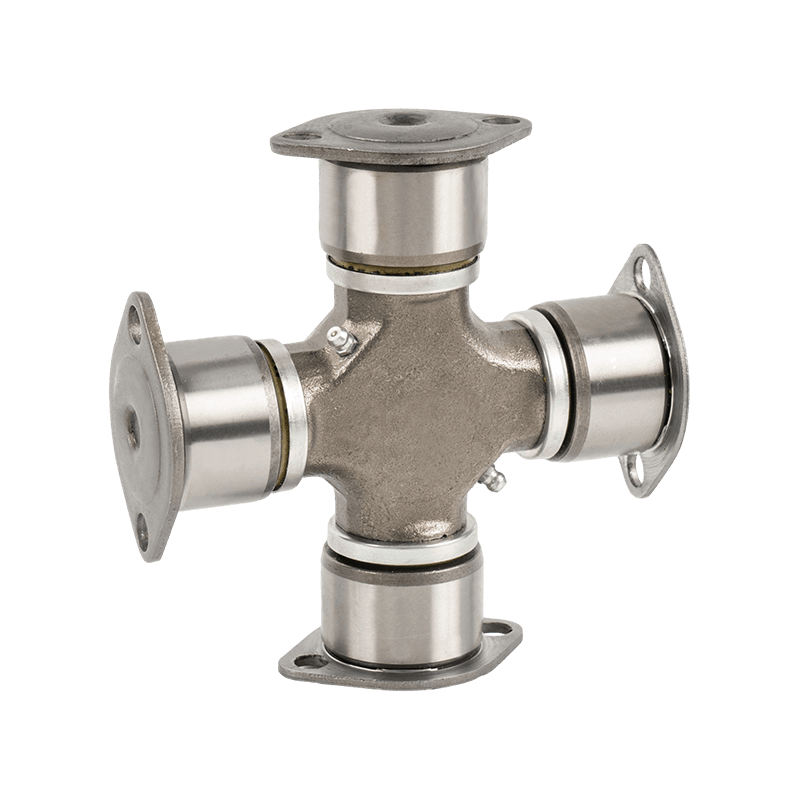

What Is a U-Joint with 4 Grooved Bearings?

A U-joint, short for universal joint, is a mechanical component that allows for the transfer of rotary motion between two shafts that are not in line with each other. It connects two drive shafts in a drivetrain and allows them to operate at different angles. U-joints are crucial for transmitting torque while accommodating the angular movement between shafts, such as when a vehicle’s axle moves as the suspension flexes.

The "4 grooved bearings" aspect refers to the design of the U-joint. While traditional U-joints may only feature two bearings (or sometimes four, in older designs), a U-joint with 4 grooved bearings incorporates additional bearing surfaces designed to provide improved load distribution and better overall performance under heavy use. The grooved bearings are strategically placed to ensure that the U-joint can handle higher stresses and provide longer-lasting functionality, which is essential for the high demands placed on automotive drivetrains.

Why Are U-Joints with 4 Grooved Bearings Important in Automotive Drivetrains?

Automotive drivetrains are complex systems that rely on numerous interconnected components to deliver power from the engine to the wheels. The drivetrain needs to efficiently transmit torque while handling various angles and stresses as the vehicle moves. U-joints, particularly those with 4 grooved bearings, help facilitate this process by offering the following benefits:

Enhanced Torque Transmission

The primary function of a U-joint is to transfer torque between two shafts while accommodating angular movement. When a vehicle’s axle moves in and out due to suspension travel or road conditions, the U-joint allows for continuous rotation without causing damage to the shafts. A U-joint with 4 grooved bearings ensures better load distribution across the bearings, which reduces wear and tear on the component and improves torque transfer efficiency. This is especially important in high-performance or off-road vehicles where the drivetrain is subjected to greater forces and stress.

Improved Durability and Longevity

One of the key reasons U-joints with 4 grooved bearings are favored in modern automotive applications is their durability. The additional bearings help to distribute the load more evenly across the joint, reducing friction and heat buildup. This not only prolongs the life of the U-joint itself but also helps prevent premature wear in other drivetrain components like drive shafts and axles. The result is a more reliable drivetrain system that can withstand the rigors of everyday driving as well as the demands of high-performance applications.

Smoother Operation

U-joints with 4 grooved bearings are designed to minimize the friction that naturally occurs when two rotating shafts meet. This reduction in friction leads to smoother operation of the drivetrain, which contributes to a quieter and more efficient ride. In particular, vehicles that are equipped with these advanced U-joints experience less vibration and noise during operation, making for a more comfortable driving experience.

Better Handling of High Angles and Stress

Drivetrain components are often subjected to significant stress, especially when navigating steep inclines, rough terrain, or tight turns. U-joints with 4 grooved bearings are engineered to handle these high-angle movements more effectively than traditional U-joints. Whether driving over uneven surfaces or taking sharp corners, these U-joints are better equipped to handle the additional stress without compromising performance or safety. This is particularly valuable for off-road vehicles, heavy-duty trucks, and performance cars that often experience extreme driving conditions.

Applications of U-Joints with 4 Grooved Bearings in Automotive Drivetrains

U-joints with 4 grooved bearings are used in a wide range of vehicles, from standard consumer cars to specialized off-road vehicles. These U-joints are essential in a variety of drivetrain configurations:

Rear-Wheel Drive (RWD) Vehicles

In rear-wheel drive vehicles, the U-joint is a critical component in the drive shaft, which connects the engine to the rear axle. The U-joint with 4 grooved bearings provides the necessary support for the drive shaft to rotate while accommodating the movement of the rear axle. This setup ensures smooth power delivery to the rear wheels, providing a stable driving experience, especially at higher speeds or when carrying heavy loads.

All-Wheel Drive (AWD) and Four-Wheel Drive (4WD) Vehicles

For all-wheel drive and four-wheel drive vehicles, U-joints with 4 grooved bearings are essential for transmitting torque to all four wheels. In these vehicles, the U-joint helps to connect the front and rear axles while allowing for the independent movement of each axle. This is especially important when off-roading or driving on uneven terrain, where the drivetrain components are subjected to greater stresses and angles.

Heavy-Duty and Commercial Vehicles

Heavy-duty trucks, commercial vehicles, and industrial machinery often use U-joints with 4 grooved bearings to handle the immense torque and stress placed on their drivetrains. These vehicles are frequently used for towing, hauling, or driving on rugged roads, so the added durability and performance of 4 grooved bearings are crucial for maintaining long-term reliability and minimizing downtime due to drivetrain failure.

Performance and Racing Vehicles

Performance cars and racing vehicles require precise and efficient power transfer for maximum performance. U-joints with 4 grooved bearings are commonly used in these vehicles to ensure that torque is transmitted smoothly under high-stress conditions. The added durability and smooth operation of these advanced U-joints are critical for maintaining control and minimizing the risk of drivetrain failure during high-speed maneuvers.

How to Maintain U-Joints with 4 Grooved Bearings

To ensure that U-joints with 4 grooved bearings continue to function optimally, regular maintenance is required. Here are a few tips for keeping these components in top condition:

Regular Lubrication

Proper lubrication is crucial for reducing friction and preventing wear on the bearings. U-joints typically feature grease fittings, allowing for easy lubrication. Make sure to apply the recommended lubricant at regular intervals to keep the U-joint operating smoothly.

Check for Wear and Damage

Over time, U-joints can become worn or damaged, especially if they are subjected to heavy stress. Regularly inspect the U-joint for signs of wear, such as excessive play, unusual noises, or grease leakage. If you notice any issues, it’s important to replace the U-joint promptly to avoid further damage to the drivetrain.

Replace Worn U-Joints

If a U-joint with 4 grooved bearings shows signs of excessive wear or damage, it should be replaced. Ignoring a worn U-joint can lead to more serious problems, such as driveline failure or damage to other drivetrain components. Replacing U-joints at the first sign of wear is essential for maintaining the safety and reliability of the vehicle.

English

English 中文简体

中文简体