Increased Longevity and Strength: Why 4 Welded Plate Type Round Bearings U-Joints Are Gaining Popularity

Content

In the world of mechanical engineering, precision, durability, and efficiency are key factors that drive the success of machinery and vehicles. For industries that rely on heavy machinery or vehicles that need to handle significant stress and movement, components such as bearings and U-joints play a crucial role. One such component that has been gaining popularity in recent years is the 4 welded plate type round bearings U-joint.

This unique type of U-joint, featuring welded plate type round bearings, has quickly become an essential part of many industries due to its exceptional strength, long-lasting durability, and improved performance.

What is a 4 Welded Plate Type Round Bearings U-Joint?

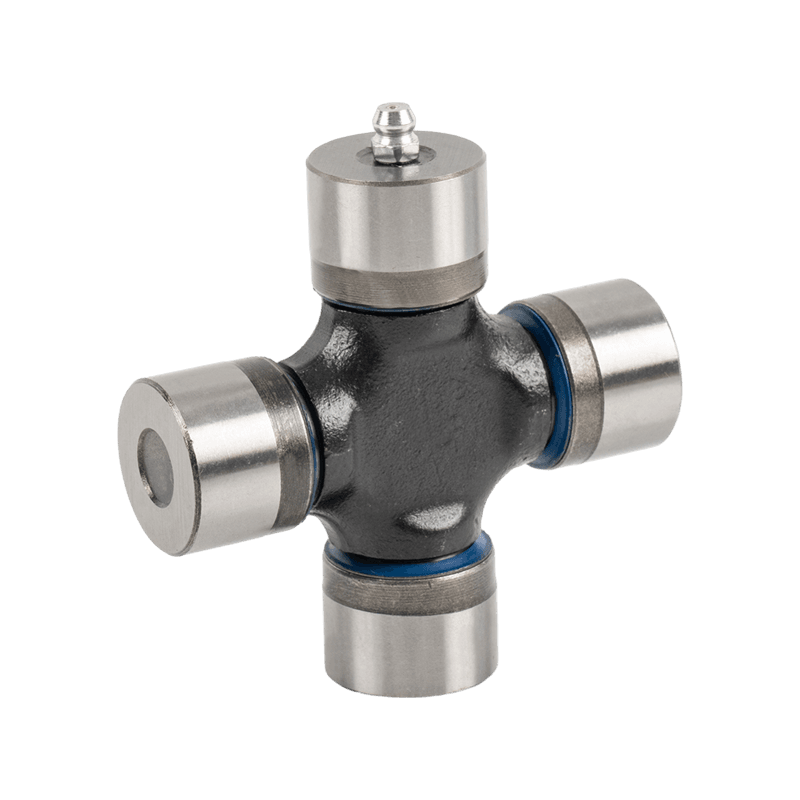

To fully appreciate the significance of the 4 welded plate type round bearings U-joint, it's important to first understand what a U-joint is and what it does. A U-joint, also known as a universal joint or Cardan joint, is a mechanical component used to connect two shafts at an angle, allowing for torque transmission while accommodating changes in the angle between the shafts. This makes it an essential part of drivetrains in vehicles, machinery, and other mechanical systems.

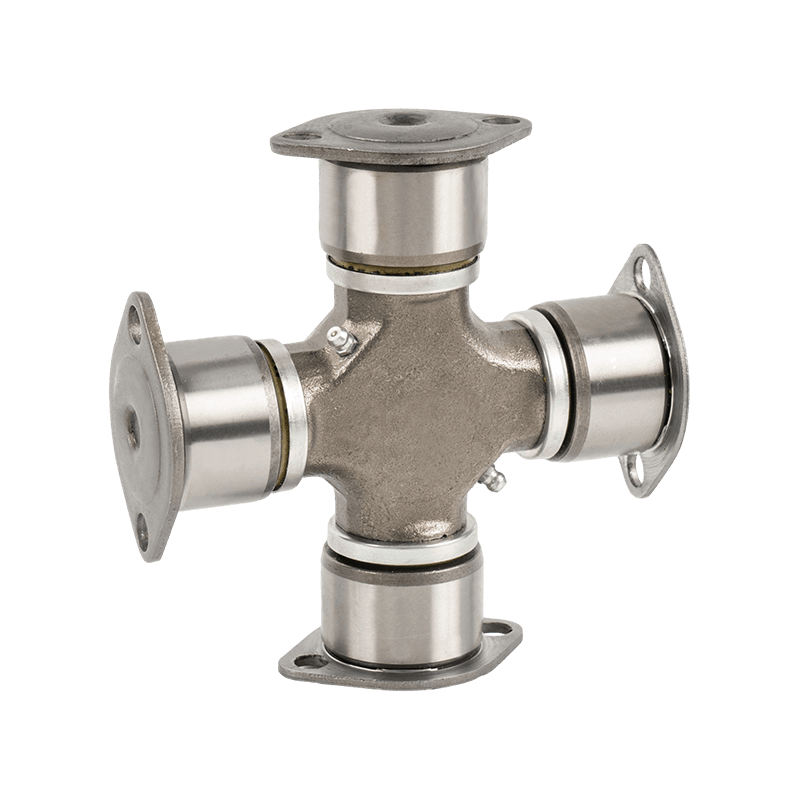

The “4 welded plate type round bearings” in this context refers to a specialized design of U-joint that incorporates four welded plates, each containing round bearings. These round bearings help distribute the load more evenly, reducing the wear and tear that would typically occur in a standard U-joint. The welded plates provide additional strength and stability, ensuring that the U-joint can handle more significant forces and endure for longer periods.

This design significantly enhances the U-joint’s performance by increasing its resistance to wear, improving load-bearing capacity, and minimizing maintenance needs.

Why 4 Welded Plate Type Round Bearings U-Joints Are Gaining Popularity

Improved Longevity and Durability

One of the primary reasons why the 4 welded plate type round bearings U-joint has gained popularity is its increased longevity. Traditional U-joints are often subjected to high levels of stress, particularly in heavy-duty applications, which can result in premature wear and failure. Over time, this can lead to increased maintenance costs and downtime, which is detrimental to businesses that rely on machinery or vehicles for their operations.

The 4 welded plate type round bearings U-joint addresses this issue by distributing the load more evenly across the bearings and the welded plates. This distribution of forces reduces the amount of strain placed on any single part of the joint, preventing excessive wear and tear. As a result, these U-joints are able to last significantly longer than traditional designs, reducing the need for frequent replacements and minimizing downtime.

In addition, the welded plates themselves offer enhanced structural integrity, making them less likely to bend or break under high-stress conditions. This combination of factors ensures that the U-joint maintains its performance over a much longer period, even under demanding conditions.

Increased Strength for Heavy-Duty Applications

Many industries, such as automotive, construction, and agriculture, rely on heavy-duty machinery that experiences significant torque and rotational forces. In these applications, strength is a critical factor in ensuring that components perform reliably under stress.

The 4 welded plate type round bearings U-joint excels in this area by offering increased strength compared to traditional U-joint designs. The welded plates provide extra support and reinforce the U-joint’s ability to handle higher levels of torque without compromising its integrity. Additionally, the round bearings within the plates allow for smoother movement, reducing the chances of sudden jolts or shocks that could damage the U-joint or surrounding components.

This increased strength makes the 4 welded plate type round bearings U-joint an ideal choice for vehicles, machinery, and equipment that need to endure heavy loads and high forces on a daily basis. Whether in construction equipment like cranes and bulldozers or in off-road vehicles, these U-joints are built to withstand the toughest environments and continue performing at their best.

Enhanced Performance and Efficiency

In addition to their durability and strength, 4 welded plate type round bearings U-joints also contribute to better overall performance and efficiency. Traditional U-joints can often experience friction, which can lead to energy loss, overheating, and reduced performance. By incorporating round bearings into the design, the 4 welded plate type round bearings U-joint reduces friction and allows for smoother rotation between shafts. This reduction in friction translates into better energy efficiency, as less power is lost to heat and resistance.

Moreover, the even distribution of load across the welded plates and bearings helps maintain consistent torque transmission between the connected shafts. This consistency is vital in ensuring that machinery or vehicles operate smoothly and reliably, especially in applications where precision and performance are key.

Reduced Maintenance Costs

With longer-lasting durability, increased strength, and smoother operation, 4 welded plate type round bearings U-joints also help reduce maintenance costs. As these U-joints are designed to endure heavy use and high-stress conditions, businesses can expect fewer breakdowns and less frequent replacements compared to standard U-joints. This leads to lower repair costs and reduced downtime for machinery, ultimately resulting in higher productivity and cost savings.

The need for less frequent maintenance is especially beneficial for industries that operate in remote locations or environments where access to spare parts and repair services may be limited. By choosing a more durable, high-performance U-joint, companies can ensure that their machinery continues to operate efficiently without incurring unnecessary costs.

Versatility Across Different Industries

Another key factor contributing to the popularity of 4 welded plate type round bearings U-joints is their versatility. These U-joints are used in a wide range of applications across different industries, including automotive, aerospace, agriculture, construction, and heavy-duty machinery. Whether it’s an agricultural vehicle that needs to withstand rough terrain or an industrial machine that requires smooth, high-torque performance, these U-joints are adaptable enough to meet the needs of various sectors.

In automotive engineering, for example, these U-joints are used in drivetrain components to connect shafts and transfer power while accommodating changes in angles. In construction, heavy-duty machines like bulldozers and cranes rely on robust U-joints to handle high levels of stress while maintaining smooth operation. Their ability to adapt to different environments and functions makes them an invaluable component in many industries.

Cost-Effective in the Long Run

While the initial cost of 4 welded plate type round bearings U-joints may be higher than traditional U-joints, their long-term cost-effectiveness is undeniable. The reduced frequency of replacements, lower maintenance requirements, and improved performance all contribute to substantial cost savings over time. For businesses operating in industries where equipment downtime or failure can result in significant losses, investing in high-quality, durable U-joints can pay off in the long run.

Moreover, these U-joints offer a great return on investment by improving the efficiency of machines and vehicles, leading to more reliable and productive operations. This makes them an attractive option for businesses looking to enhance the reliability and performance of their equipment without constantly having to deal with expensive repairs or replacements.

English

English 中文简体

中文简体