Toyo Universal Joint Drives Innovation in Automotive and Industrial Applications

Content

- 1 The Role of Universal Joints in Power Transmission

- 2 Automotive Applications of Toyo Universal Joints

- 3 Industrial Applications of Toyo Universal Joints

- 4 Key Advantages of Toyo Universal Joints

- 5 Manufacturing and Quality Standards

- 6 Market Trends Driving Growth

- 7 Applications Across Different Industries

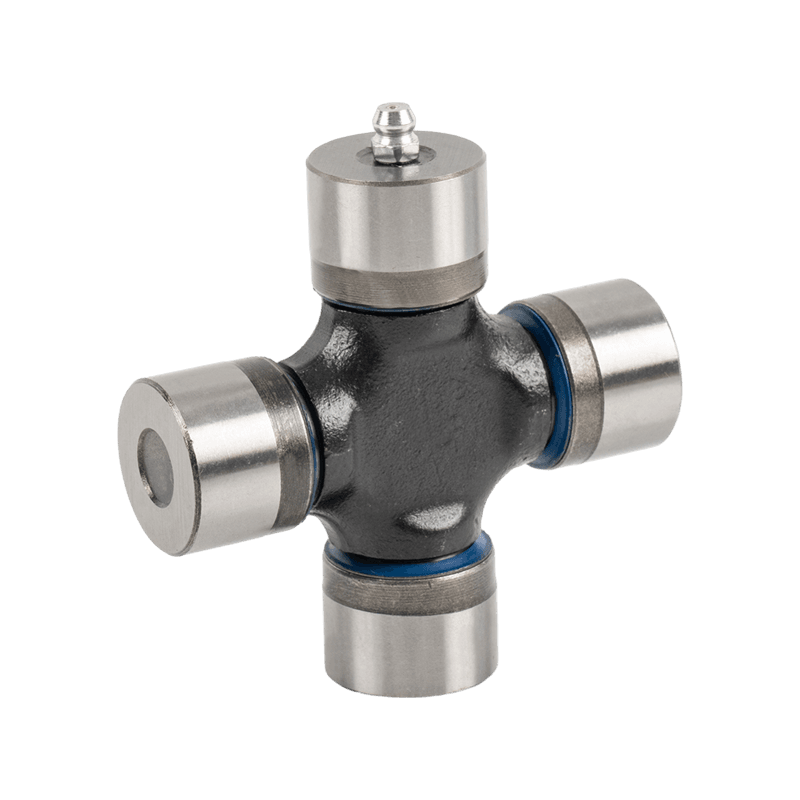

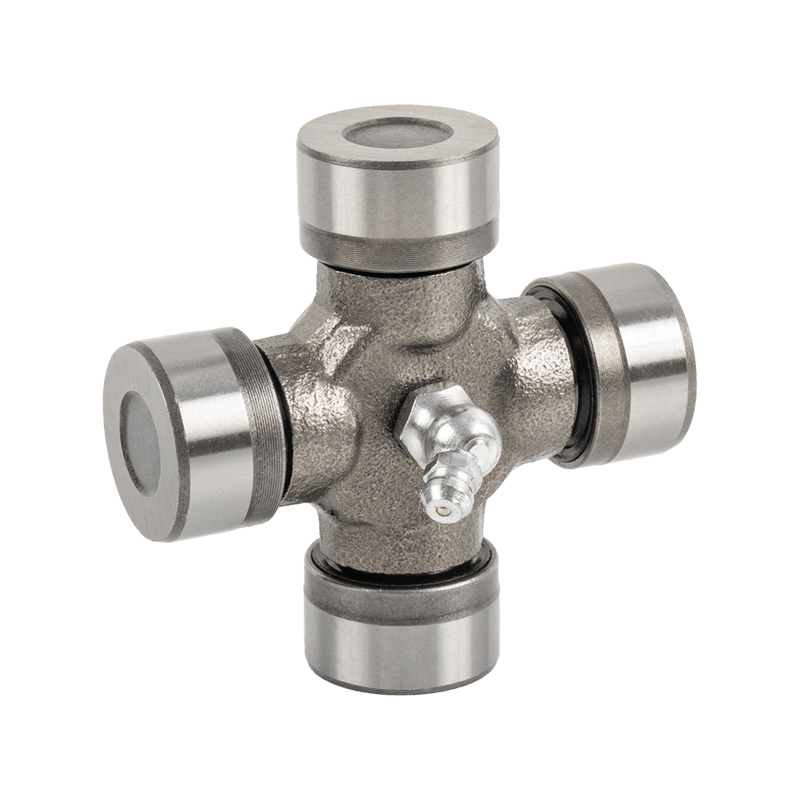

In the modern era of automotive engineering and industrial machinery, efficiency, reliability, and precision are more critical than ever. From passenger cars and heavy-duty trucks to agricultural machinery and automated industrial systems, smooth power transmission is essential for performance and safety. At the heart of many of these systems is a seemingly small but indispensable component: the Toyo Universal Joint.

As a professional manufacturer and supplier of Toyo Universal Joints, we have witnessed a remarkable surge in demand for this high-performance mechanical solution. Across automotive and industrial sectors, engineers and technicians are increasingly relying on Toyo Universal Joints to ensure optimal torque transmission, reduce wear and vibration, and extend the service life of critical equipment.

The Role of Universal Joints in Power Transmission

A universal joint, also known as a U-joint or Cardan joint, is a mechanical device used to transmit rotational power between two shafts that are not in a straight line. By allowing angular misalignment between connected shafts, universal joints are essential for the smooth operation of vehicles, machinery, and industrial equipment.

The Toyo Universal Joint stands out in this category due to its precise engineering, durable materials, and advanced manufacturing techniques. Unlike conventional U-joints, Toyo’s design emphasizes:

- High torsional strength

- Reduced friction and wear

- Vibration damping

- Long operational lifespan

These features make it suitable for applications ranging from automotive drivetrains to industrial conveyor systems.

Automotive Applications of Toyo Universal Joints

The automotive industry has always been a major consumer of universal joints. Modern vehicles, from light-duty cars to heavy trucks, require reliable U-joints to manage the dynamic motion of driveshafts and other rotating components.

Enhancing Drivetrain Performance

In vehicles, the drivetrain must transmit power from the engine and transmission to the wheels while accommodating movement caused by suspension travel and road conditions. A poorly designed universal joint can lead to:

- Vibrations

- Premature wear

- Noise

- Reduced fuel efficiency

The Toyo Universal Joint is engineered to handle high torque loads while maintaining smooth rotation, ensuring that power is efficiently transmitted even under extreme driving conditions. Its precision-balanced design minimizes vibration and improves overall ride comfort.

Heavy-Duty and Off-Road Vehicles

Heavy-duty trucks, construction vehicles, and off-road machines face even more demanding conditions. They operate under heavy loads, uneven terrain, and high-stress environments.

Toyo Universal Joints provide:

- Superior strength and durability

- Resistance to impact and shock loads

- Extended service intervals

- Reduced downtime for maintenance

For fleet operators and industrial vehicle manufacturers, these benefits translate into lower operational costs and higher reliability.

Performance and Sports Vehicles

High-performance and sports vehicles require precision-engineered components to maximize responsiveness and torque delivery. Toyo Universal Joints are designed with tight tolerances and high-quality materials to meet these rigorous performance requirements.

By integrating Toyo Universal Joints, manufacturers can achieve:

- Smooth power transfer at high RPMs

- Reduced driveline backlash

- Improved acceleration and handling

This makes them ideal for performance cars and specialty automotive applications.

Industrial Applications of Toyo Universal Joints

Beyond automotive uses, Toyo Universal Joints are indispensable in a wide range of industrial machinery. These components ensure reliable power transmission in systems that experience angular misalignment, vibration, and heavy loads.

Manufacturing and Automation Equipment

In automated production lines and CNC machinery, rotational components must transfer power accurately to maintain precision. Misalignment or vibration can cause production errors and equipment wear.

Toyo Universal Joints provide:

- Smooth rotational power transfer

- Reduced vibration and backlash

- Long-term reliability for continuous operation

These features make them ideal for factory automation, robotics, and conveyor systems.

Agricultural and Construction Machinery

Tractors, harvesters, excavators, and other heavy machinery rely on universal joints to transmit torque between PTO shafts, drive systems, and implements.

Advantages of Toyo Universal Joints in these applications include:

- Withstanding heavy loads and variable torque

- Tolerance to dirt, mud, and harsh outdoor conditions

- Minimal maintenance requirements

By choosing high-quality Toyo Universal Joints, agricultural and construction operators can reduce equipment downtime and improve operational efficiency.

Industrial Conveyors and Material Handling Systems

Conveyors, mixers, and other rotating machinery often operate under continuous loads with shafts that are slightly misaligned.

Toyo Universal Joints ensure:

- Continuous, reliable power transmission

- Reduced wear on bearings and shafts

- Smooth operation under variable load conditions

Industrial operators benefit from improved productivity and lower maintenance costs.

Key Advantages of Toyo Universal Joints

Across automotive and industrial applications, Toyo Universal Joints provide several advantages that distinguish them from conventional universal joints:

- Durability: High-strength steel construction and precision manufacturing ensure long-lasting performance under high stress.

- Smooth Operation: Balanced design minimizes vibrations, noise, and torque fluctuations.

- Versatility: Suitable for applications ranging from light vehicles to heavy machinery.

- Maintenance Efficiency: Reduced wear and lubrication requirements extend service intervals.

- Adaptability: Available in multiple sizes and configurations to meet different torque and angular requirements.

These attributes make Toyo Universal Joints a reliable choice for engineers and technicians worldwide.

Manufacturing and Quality Standards

As a manufacturer, producing reliable Toyo Universal Joints requires strict adherence to quality standards and advanced production techniques. Key aspects include:

- Material Selection: High-strength alloy steels or heat-treated metals ensure durability and resistance to fatigue.

- Precision Machining: CNC machining and tight tolerances guarantee accurate fit and smooth operation.

- Surface Treatment: Coatings such as phosphating or nitriding enhance wear resistance and corrosion protection.

- Testing: Each joint undergoes rigorous torque, load, and fatigue testing to ensure compliance with automotive and industrial standards.

These manufacturing processes ensure that Toyo Universal Joints deliver consistent performance in demanding environments.

Market Trends Driving Growth

Several trends contribute to the rising demand for Toyo Universal Joints globally:

- Growth in Automotive Manufacturing: Expanding automotive markets, especially in Asia, Africa, and South America, are driving demand for high-quality universal joints.

- Industrial Automation Expansion: Factories increasingly rely on machinery that requires precision power transmission components.

- Heavy Equipment and Off-Road Vehicle Growth: Construction, agriculture, and mining sectors continue to invest in robust machinery.

- Maintenance and Replacement Cycles: Aging vehicle fleets and industrial equipment increase the need for replacement joints.

- Focus on Efficiency and Performance: OEMs and aftermarket suppliers seek components that improve driveline efficiency and reduce downtime.

As a result, Toyo Universal Joints are becoming an essential component for OEMs, distributors, and industrial users alike.

Applications Across Different Industries

The versatility of Toyo Universal Joints enables their use in multiple sectors:

- Automotive OEMs and Aftermarket: Passenger cars, SUVs, trucks, and sports vehicles

- Heavy Machinery and Construction: Excavators, bulldozers, loaders, and cranes

- Agriculture: Tractors, harvesters, PTO systems, and farm implements

- Industrial Equipment: Conveyors, mixers, robotic arms, and material handling systems

- Energy and Mining: Drilling rigs, turbines, and shaft-driven machinery

This broad application range ensures that Toyo Universal Joints maintain high demand in global markets.

English

English 中文简体

中文简体