Exploring the Benefits of Upgrading U-Joints in PTO Shafts for Heavy Machinery

Content

Power Take-Off (PTO) shafts are critical components in many heavy machinery applications, including agricultural, industrial, and construction equipment. These shafts transfer mechanical power from the engine of a vehicle to the implements it is powering, such as mowers, augers, and pumps. One key element of a PTO shaft system is the U-joint, which plays an essential role in maintaining smooth power transfer and ensuring that the machinery operates efficiently and safely.

Over time, the U-Joint of PTO Shafts may experience wear and tear due to constant operation and exposure to harsh conditions. Upgrading the U-Joint of PTO Shafts can significantly improve the performance, longevity, and safety of the machinery.

Understanding U-Joint of PTO Shafts

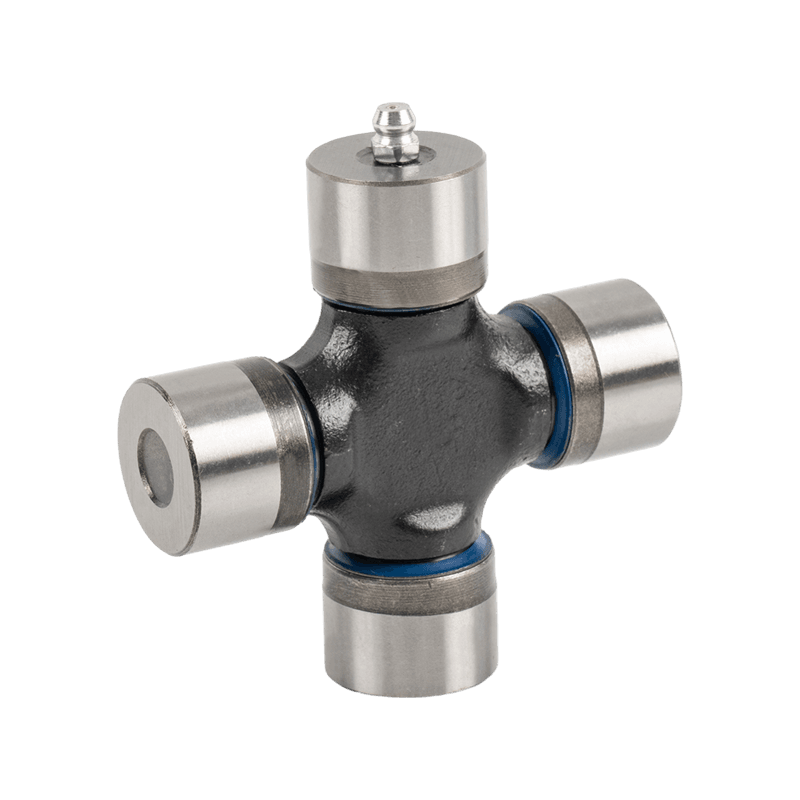

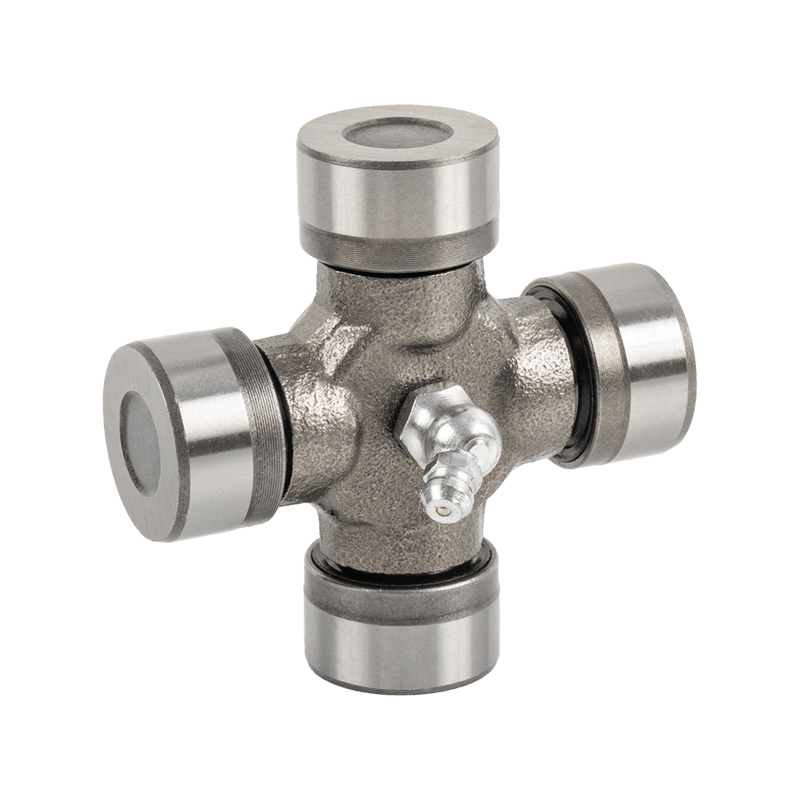

U-joints, also known as universal joints, are mechanical components that connect two shafts and allow them to transmit rotary motion while accommodating changes in angle between the shafts. In PTO shafts, U-joints allow for flexibility in the transfer of power, enabling the shaft to rotate even when it is not perfectly aligned with the driven implement. The U-joint ensures that power is efficiently transferred from the engine to the equipment, even when the angle of the shaft changes during operation.

The U-joint consists of a cross with four arms, which are connected to the yokes of the PTO shaft. The arms are equipped with bearings that allow them to pivot, which enables the shaft to operate at different angles without losing power transmission. As one of the most essential components of the PTO shaft system, the U-joint must be robust and able to withstand the high levels of stress and torque generated during heavy machinery operations.

Why Upgrade U-Joint of PTO Shafts?

While U-Joint of PTO Shafts are designed for durability, they can wear out over time due to the constant rotation and high torque they endure during normal use. Upgrading these components can provide several benefits that contribute to better machinery performance and reduce the risk of costly downtime.

Enhanced Durability and Longevity

Upgrading U-Joint of PTO Shafts with higher-quality components can significantly increase their lifespan. Standard U-joints may wear out due to the friction and stress they experience, leading to cracks, fractures, and eventual failure. High-quality U-joints, often made from stronger materials such as high-grade steel or composite alloys, are designed to withstand more intense forces and last longer under demanding conditions.

For heavy machinery used in industries such as agriculture, construction, and mining, durability is a crucial factor. The continuous operation of PTO shafts in challenging environments, such as rough terrains, high-speed applications, and extreme weather conditions, can accelerate wear. By upgrading U-joints with more durable components, machinery operators can reduce the frequency of replacements, ensuring that the PTO shaft system operates smoothly for a more extended period.

Improved Power Transfer Efficiency

U-joints that are worn or of low quality can cause power loss during the transfer from the PTO shaft to the implement. When U-joints are not functioning optimally, they can create friction and misalignment that reduces the efficiency of power transmission. This inefficiency can lead to decreased performance of the equipment and higher fuel consumption, as the engine has to work harder to generate the same amount of power.

Upgrading to higher-quality U-joints ensures smoother operation, reducing friction and improving the overall power transfer efficiency. By minimizing energy loss, upgraded U-joints help machinery perform better and reduce the load on the engine, leading to improved fuel efficiency. For businesses relying on heavy machinery for large-scale operations, this can result in significant cost savings in terms of fuel and operational costs.

Reduced Downtime and Maintenance Costs

Downtime is one of the most significant concerns for businesses that rely on heavy machinery, as it leads to lost productivity and higher maintenance costs. When U-joints fail, the PTO shaft system can become inoperative, causing delays in operations and the need for repairs. Depending on the extent of the damage, replacing worn U-joints or repairing the PTO shaft system can be costly and time-consuming.

Upgrading U-Joint of PTO Shafts can help reduce the risk of unexpected failures. By choosing high-quality, durable U-joints that are specifically designed for the operating conditions of the machinery, operators can prevent premature wear and reduce the likelihood of failure. As a result, businesses experience less downtime, which ultimately leads to more efficient operations and lower maintenance expenses.

Improved Safety and Reduced Risk of Failure

U-joint failure in PTO shafts can pose significant safety risks, especially when the machinery is operating at high speeds or under heavy loads. A damaged or worn U-joint can cause the PTO shaft to break or detach, which can lead to dangerous situations for operators and those working nearby. In extreme cases, U-joint failure can cause severe equipment damage, personal injury, or even fatalities.

Upgrading U-joints to stronger, more reliable components helps reduce the likelihood of sudden failures, ensuring that the machinery operates safely. A high-quality U-joint will be more resistant to fatigue, corrosion, and other stress factors that can cause premature failure. This contributes to a safer working environment, as the risk of mechanical failures is significantly reduced.

Better Performance in Harsh Conditions

Heavy machinery is often used in challenging environments, such as construction sites, agricultural fields, and mining operations, where extreme weather, rough terrain, and heavy loads are the norm. In these conditions, PTO shafts and U-joints are exposed to higher levels of stress and fatigue. Standard U-joints may not be able to handle these tough conditions, leading to faster wear and more frequent breakdowns.

Upgraded U-joints are designed to perform better in these harsh conditions. They are made from materials that offer better resistance to corrosion, heat, and abrasion, making them ideal for use in environments where moisture, dirt, and extreme temperatures are common. Additionally, high-quality U-joints are engineered to handle higher torque and more demanding workloads, ensuring that the PTO shaft system continues to function reliably, even under heavy use.

Cost Savings in the Long Run

While upgrading U-joints may involve a higher upfront cost compared to standard replacements, the long-term benefits often outweigh the initial investment. Upgraded U-joints offer superior performance, longer lifespans, and better resistance to wear, which means fewer replacements and lower maintenance costs over time. Additionally, the enhanced power transfer efficiency can lead to savings in fuel costs, further offsetting the initial cost of upgrading.

For businesses that rely on heavy machinery, reducing downtime and improving operational efficiency can result in significant cost savings in the long run. By investing in upgraded U-joints, companies can extend the life of their equipment and reduce the frequency of repairs, ultimately saving money and improving the overall profitability of their operations.

Factors to Consider When Upgrading U-Joint of PTO Shafts

When upgrading U-Joint of PTO Shafts, it is important to consider several factors to ensure that the replacement parts meet the specific needs of your machinery and operating conditions:

Material Quality

Choose U-joints made from high-quality materials such as heat-treated steel, which offers better strength and durability. Some U-joints are also coated with corrosion-resistant materials to protect them from rust and wear.

Torque Rating

Ensure that the U-joints you select are rated to handle the torque requirements of your machinery. Overloading the U-joints can lead to premature failure, so it is essential to select components that match the specifications of your PTO shaft system.

Size and Compatibility

U-joints come in various sizes and designs, so it is essential to select the right size that matches your PTO shaft’s yokes and the machinery's specific requirements. Check the manufacturer’s specifications to ensure compatibility.

Environmental Conditions

Consider the environment in which your machinery operates. If your equipment is exposed to extreme temperatures, moisture, or chemicals, choose U-joints designed for such conditions to ensure better performance and longevity.

Brand and Quality Assurance

When upgrading U-joints, choose reputable brands known for manufacturing high-quality components. Ensure that the U-joints come with a warranty and have been tested for reliability and performance under real-world conditions.

English

English 中文简体

中文简体