How China Cardan Joints Are Revolutionizing Industrial Applications

Content

In the ever-evolving world of industrial machinery and automotive engineering, innovation is key to improving performance, efficiency, and safety. One such innovation that has steadily gained attention and importance is the Cardan joint, also known as a universal joint (U-joint). Originally designed for use in the automotive sector, China Cardan Joints have found applications in a wide range of industrial sectors, from construction and agriculture to energy and manufacturing.

China, as a global leader in manufacturing, has played a pivotal role in advancing Cardan joint technology. With cutting-edge innovations, high-quality production capabilities, and growing export markets, Chinese manufacturers are now shaping the future of industrial applications by revolutionizing the way Cardan joints are used.

What Are Cardan Joints?

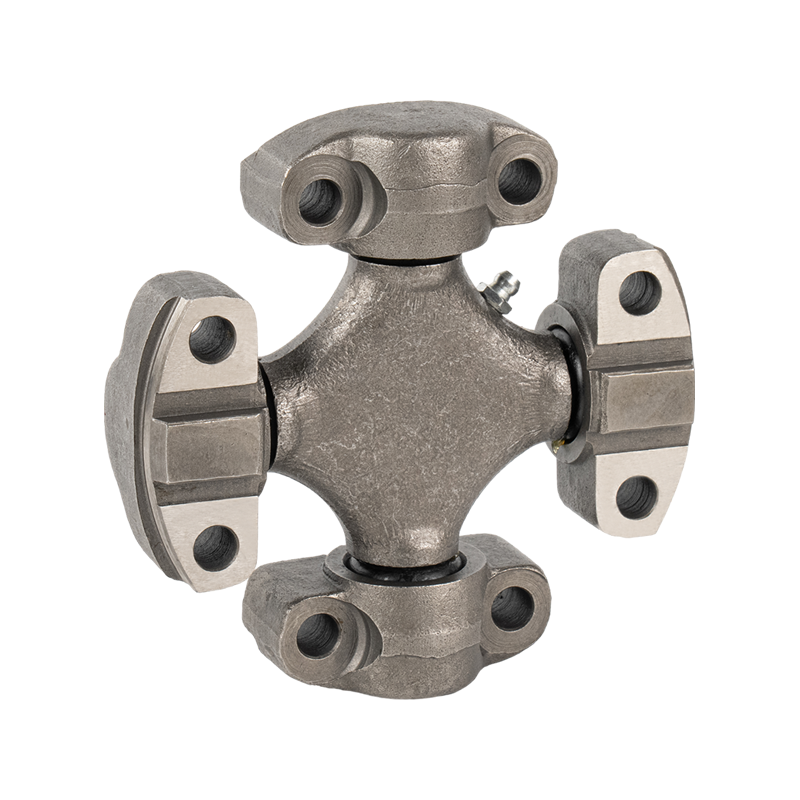

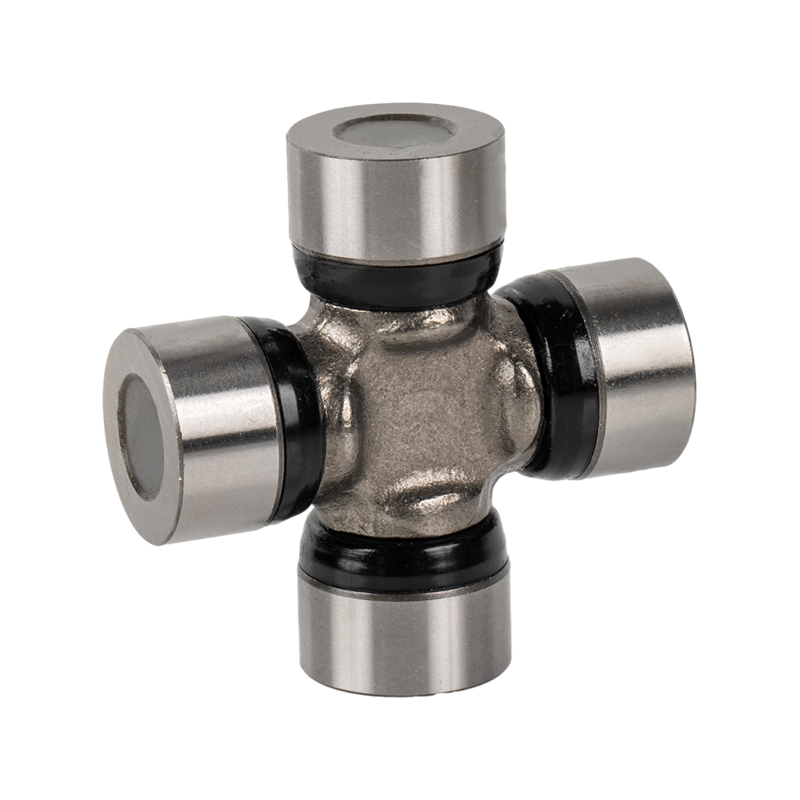

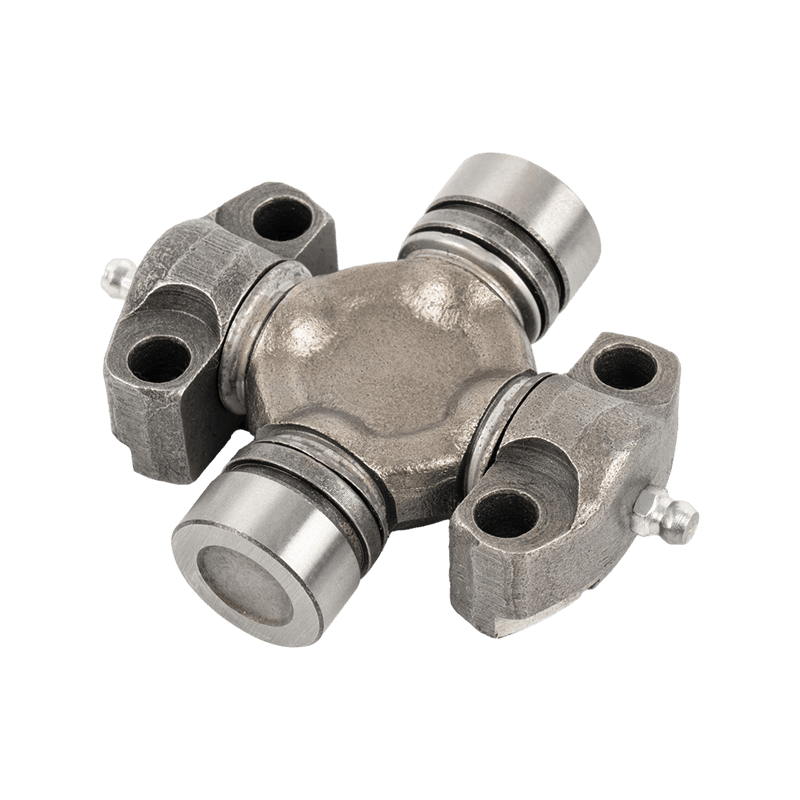

A Cardan joint, or universal joint, is a mechanical component that connects two rotating shafts, enabling them to transfer rotary motion while accommodating varying angles between the shafts. The joint is primarily used to transmit torque and rotational power in situations where two shafts are not aligned in a straight line. This type of joint is crucial for enabling motion in machines that require flexibility, such as vehicles, industrial machinery, and heavy equipment.

Typically made of durable materials such as steel, these joints feature cross-shaped components with bearings that allow for the transfer of power in an efficient and smooth manner. The primary advantage of a Cardan joint is its ability to transmit power while compensating for angular misalignments, making it suitable for a wide range of mechanical systems.

The Role of China in Cardan Joint Manufacturing

China has become a global powerhouse in the manufacturing of Cardan joints. The country’s well-established industrial base, skilled labor force, and technological advancements in material science and precision manufacturing have positioned it as a dominant player in the market. Chinese manufacturers offer a broad range of Cardan joints designed for different industrial applications, including automotive, agricultural machinery, construction, and industrial processing.

The Chinese Cardan joint industry has experienced rapid growth, fueled by domestic demand for machinery and the increasing demand for exports. Manufacturers in China have adapted to global market requirements by focusing on innovation, product quality, and cost efficiency. As a result, Chinese-made Cardan joints are now being used across the world in diverse industries, from automotive assembly lines to heavy-duty construction equipment.

Innovations in Cardan Joint Design

Over the years, Cardan joints have evolved significantly, particularly with advancements in materials and design. Chinese manufacturers have been at the forefront of introducing new technologies and features that enhance the performance and durability of these components. Key innovations include:

High-Strength Materials for Increased Durability

One of the key challenges with Cardan joints is ensuring that they can withstand high levels of stress and torque without experiencing wear or failure. To address this, many Chinese manufacturers have incorporated advanced materials like high-carbon steel, alloy steel, and other composite materials into their designs. These materials improve the overall strength, wear resistance, and longevity of the joints, making them suitable for heavy-duty industrial applications.

Precision Engineering for Improved Performance

Precision is crucial in the production of Cardan joints. Even the slightest misalignment or imperfection in the joint can lead to premature wear or failure of machinery. Chinese manufacturers have invested heavily in state-of-the-art manufacturing technologies, such as computer numerical control (CNC) machining and 3D modeling, to produce highly precise Cardan joints. These technologies ensure that each joint is perfectly manufactured to meet the exact specifications required for optimal performance.

Enhanced Lubrication Systems

Lubrication is another important factor that affects the performance and lifespan of Cardan joints. Without proper lubrication, friction can cause excessive wear and failure of the joint. To address this, modern Chinese Cardan joints are designed with enhanced lubrication systems, such as sealed bearings and self-lubricating materials, which reduce friction and prevent the joints from overheating.

Customization for Specific Applications

Recognizing that different industries have unique requirements, Chinese manufacturers have increasingly focused on offering customizable Cardan joints tailored to specific applications. Whether it’s for agricultural machinery, mining equipment, or energy production, Chinese manufacturers can provide Cardan joints in a variety of sizes, materials, and configurations to meet the precise demands of different industries.

Key Industrial Applications of China’s Cardan Joints

The versatility and reliability of Cardan joints make them indispensable in a wide range of industrial sectors. Below, we highlight some of the key areas where Chinese-made Cardan joints are making a significant impact.

Automotive Industry

Cardan joints have long been used in the automotive industry to connect different parts of the drivetrain. They are integral to the functioning of rear-wheel drive and all-wheel drive vehicles, transmitting torque from the engine to the wheels while accommodating changes in angle. With China’s growing automotive manufacturing industry, Cardan joints have become a key component in both domestic and international vehicle production.

Chinese manufacturers supply high-quality, cost-effective Cardan joints to carmakers around the world, helping them meet the growing demand for both traditional and electric vehicles. Innovations in Cardan joint design, such as lightweight materials and improved durability, are making them an even more attractive option for modern vehicle designs.

Agricultural Machinery

Agricultural equipment, such as tractors, harvesters, and plows, requires robust and reliable Cardan joints to transfer power between rotating shafts in harsh conditions. China’s agricultural machinery manufacturers are increasingly relying on high-performance Cardan joints to ensure that their equipment can operate efficiently in challenging environments.

The ability of Chinese-made Cardan joints to withstand extreme weather conditions, heavy loads, and long operational hours has made them a popular choice in the agricultural sector. With growing global demand for food production and mechanization, the role of Cardan joints in agricultural machinery is expected to expand even further.

Construction and Mining Equipment

Heavy-duty construction and mining equipment, such as excavators, bulldozers, and cranes, require Cardan joints that can handle significant stress and torque. China’s construction machinery industry is a major consumer of high-strength, durable Cardan joints that can ensure the reliable operation of these large machines.

As China continues to lead the global construction and infrastructure sectors, the demand for Cardan joints in these industries has grown. These joints ensure the efficient transmission of power in machinery used for earthmoving, material handling, and mining, even in the harshest environments.

Renewable Energy Sector

With the global shift towards renewable energy, particularly wind and solar power, Cardan joints have found an important role in the energy sector. Wind turbines, for example, require Cardan joints to connect and transmit power between rotating blades and the generator. Similarly, solar tracking systems use Cardan joints to adjust the angles of solar panels to capture the most sunlight.

Chinese manufacturers are increasingly focusing on developing high-performance Cardan joints that can meet the specific requirements of renewable energy applications. As the world continues to invest in clean energy technologies, China’s Cardan joints are helping drive the industry forward.

Benefits of China’s Cardan Joints in Industrial Applications

The growing adoption of Chinese-made Cardan joints in industrial applications can be attributed to several key benefits:

Cost Efficiency

One of the main advantages of Chinese Cardan joints is their cost-effectiveness. By leveraging economies of scale, advanced manufacturing techniques, and competitive labor costs, Chinese manufacturers are able to produce high-quality joints at a fraction of the price of their competitors. This makes Chinese Cardan joints an attractive option for industries looking to balance performance and budget.

High Performance and Reliability

China’s focus on precision engineering and the use of high-strength materials ensures that its Cardan joints perform reliably in demanding conditions. Whether it’s automotive drivetrains, agricultural machinery, or construction equipment, these joints are designed to provide smooth operation and minimal maintenance, even under heavy loads.

Global Reach

China’s Cardan joints are not limited to the domestic market. Manufacturers in China have established a strong global presence, exporting their products to countries around the world. The country’s ability to produce large quantities of Cardan joints while maintaining high standards of quality has made it a trusted supplier for industries across the globe.

English

English 中文简体

中文简体