Why Russia Cross Joints Are Crucial for Reliable Power Transmission

Power transmission plays a crucial role in the performance of heavy machinery, vehicles, and various mechanical systems. Whether it’s a construction machine, agricultural equipment, or automotive vehicle, reliable power transmission ensures that all components function efficiently and safely. One of the key components in these power transmission systems is the cross joint, often referred to as a universal joint (U-joint). Among the various types of U-joints available, Russia cross joints have earned a reputation for their high durability, precision, and efficiency in delivering power across different mechanical systems.

What is a Cross Joint?

Before delving into the specifics of Russia cross joints, it's essential to understand what a cross joint is and how it functions in power transmission systems.

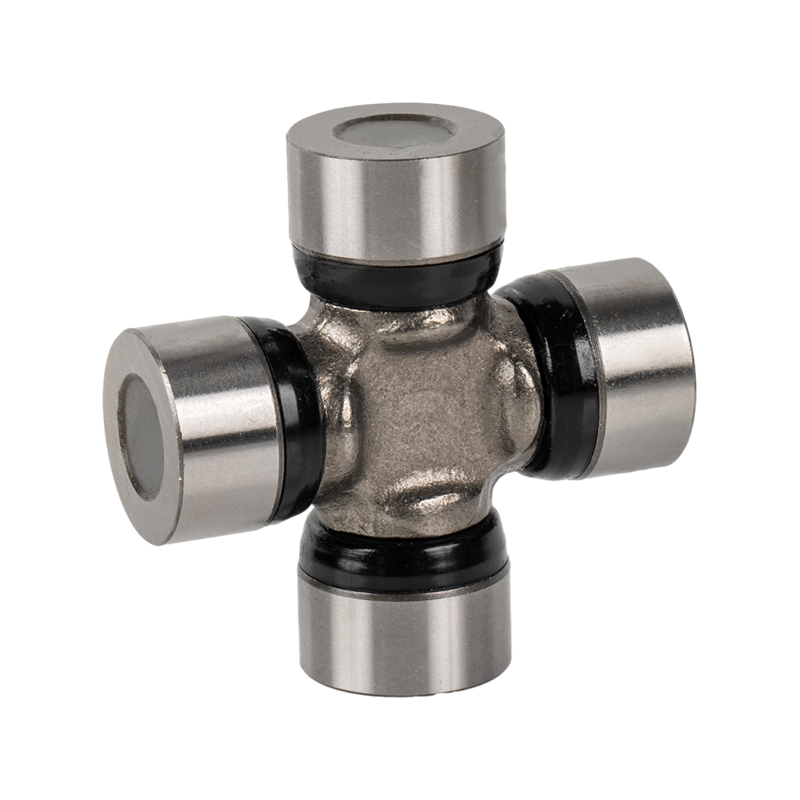

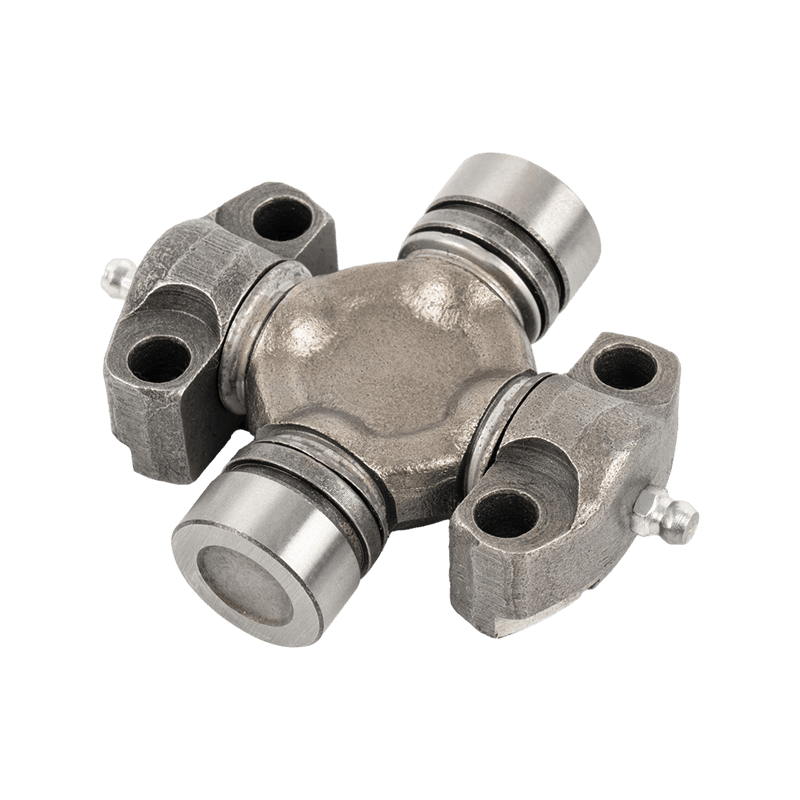

A cross joint (also known as a universal joint) is a mechanical component used to transfer rotational motion between two shafts that are not aligned with each other. It is designed to compensate for the angle between the shafts, allowing power to be transmitted smoothly even when the shafts are positioned at different angles. The cross joint consists of a cross-shaped component with four arms, connecting the two shafts at an angle.

In power transmission systems, cross joints are crucial because they allow for continuous, uninterrupted rotation between parts that cannot be directly connected. These joints are commonly found in various applications, including in driveshafts of vehicles, machinery in construction and mining, agricultural equipment, and more.

The Function of Russia Cross Joints in Power Transmission Systems

Russia cross joints are designed with high-quality materials and manufacturing precision, making them highly effective in transmitting power across a wide range of mechanical systems. Let’s take a closer look at their key functions and how they contribute to reliable power transmission:

1. Smooth Power Transmission

One of the primary functions of any cross joint, including Russia cross joints, is to ensure smooth power transmission between two shafts. In heavy machinery, power needs to be transmitted from the engine or motor to various moving parts, such as wheels, tracks, or rotating mechanisms. Russia cross joints excel at maintaining consistent and smooth power delivery, ensuring that the machinery operates at its full capacity.

By compensating for changes in angles between the connected shafts, Russia cross joints eliminate the need for perfect alignment, which is often difficult to achieve in heavy machinery. This ensures that power can be delivered efficiently, reducing the risk of mechanical failures caused by uneven or interrupted power flow.

2. Flexibility for Varied Angles

Russia cross joints are particularly beneficial in systems where shafts operate at varying angles. For example, in automotive driveshafts, the angle between the engine and the wheels can change as the vehicle moves or the suspension system adjusts. Russia cross joints are designed to handle these angle variations without losing the efficiency of power transmission.

In heavy equipment such as excavators, bulldozers, or tractors, the shafts often need to transmit power to different parts of the machinery, such as hydraulic systems or rotating blades, which may operate at different angles. Russia cross joints provide the flexibility required for such applications, enabling smooth and reliable power transmission even in the most demanding environments.

3. Durability in Harsh Conditions

Heavy-duty machinery often operates in challenging conditions, including extreme temperatures, dust, dirt, and vibrations. The components of the power transmission system, especially the cross joints, need to be robust and durable to withstand these harsh environments. Russia cross joints are manufactured using high-quality materials such as alloy steels, which offer superior resistance to wear and corrosion.

This durability ensures that Russia cross joints can function efficiently even in the most demanding conditions. Whether in mining operations, construction sites, or agricultural fields, Russia cross joints can endure the stresses of constant use without compromising on performance. Their ability to resist wear and tear also extends the lifespan of machinery, reducing the frequency of repairs or replacements.

4. Enhanced Load-Bearing Capacity

Russia cross joints are designed to handle high torque loads, making them suitable for applications that require heavy lifting or force transmission. Heavy machinery like cranes, bulldozers, and mining trucks often operate under significant stress, requiring reliable components that can withstand high levels of torque and pressure.

The high load-bearing capacity of Russia cross joints makes them ideal for such applications. By efficiently distributing the torque between shafts, Russia cross joints prevent the build-up of excessive pressure, reducing the likelihood of equipment failure due to overstressed parts.

5. Reduced Maintenance Costs

One of the key benefits of using Russia cross joints in power transmission systems is the reduction in maintenance costs. Regular maintenance and repairs are essential for keeping machinery in good working condition. However, worn-out or damaged cross joints can lead to increased downtime and higher repair costs. Russia cross joints, with their enhanced durability and long lifespan, help reduce the frequency of repairs or replacements, ultimately lowering overall maintenance costs.

Additionally, Russia cross joints minimize the risk of sudden equipment failures, which can result in costly repairs and lost productivity. By ensuring that power transmission systems remain reliable, these cross joints contribute to the overall efficiency of machinery, helping to keep operational costs under control.

6. Consistent Performance Over Time

The performance of any machinery or vehicle is highly dependent on the reliability of its components. As part of the power transmission system, cross joints need to deliver consistent performance to ensure the smooth operation of the entire machine. Russia cross joints are engineered to maintain high performance even after prolonged use, ensuring that power is transmitted efficiently over time.

By maintaining stable performance under a wide range of operating conditions, Russia cross joints help prevent disruptions in the power flow. This consistent performance is crucial for industries that rely on heavy machinery, as it ensures that the equipment is always ready for use, minimizing the risk of delays or interruptions.

7. Compatibility with a Wide Range of Machinery

Russia cross joints are highly versatile and can be used in a wide variety of machinery and vehicles. From automotive driveshafts to construction equipment, mining machinery, and agricultural vehicles, Russia cross joints are designed to meet the specific needs of different applications. Their compatibility with a broad range of systems makes them a preferred choice for industries that require universal parts for different types of equipment.

Whether you are working with an excavator, dump truck, tractor, or any other heavy-duty machine, Russia cross joints can be adapted to ensure reliable power transmission across all parts of the equipment.

Advantages of Russia Cross Joints Over Other Types

While there are many types of cross joints available in the market, Russia cross joints stand out due to their high-quality materials, manufacturing precision, and ability to handle demanding conditions. Some of the advantages they offer over other types of cross joints include:

-

Enhanced Durability: Russia cross joints are built to withstand harsh environments, reducing the need for frequent repairs or replacements.

-

Better Load Handling: These joints can handle higher torque and pressure, making them ideal for heavy-duty applications.

-

Superior Flexibility: Russia cross joints can handle varying angles between shafts, ensuring smooth power transmission even in challenging conditions.

-

Longer Lifespan: The durability and design of Russia cross joints contribute to their long lifespan, reducing downtime and maintenance costs.

English

English 中文简体

中文简体