Why Komatsu U-Joint is a Key Component in Heavy Equipment Performance

In the world of heavy machinery, where reliability, durability, and performance are crucial, every component must work seamlessly to ensure optimal functionality. One of the most vital components in construction, mining, and other heavy-duty machines is the U-joint (universal joint). Among the leading brands in heavy equipment manufacturing, Komatsu U-joints have earned a reputation for their exceptional performance and durability.

Komatsu is a globally recognized leader in the manufacturing of construction and mining equipment. Their U-joints are engineered to handle the toughest conditions and provide reliable power transmission across a range of heavy-duty applications.

What is a U-Joint?

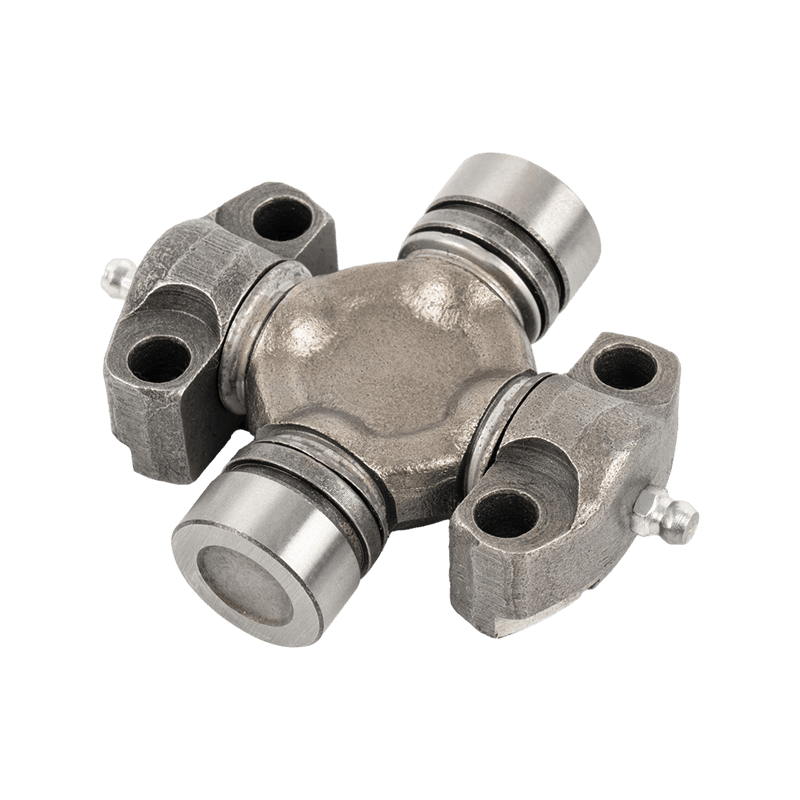

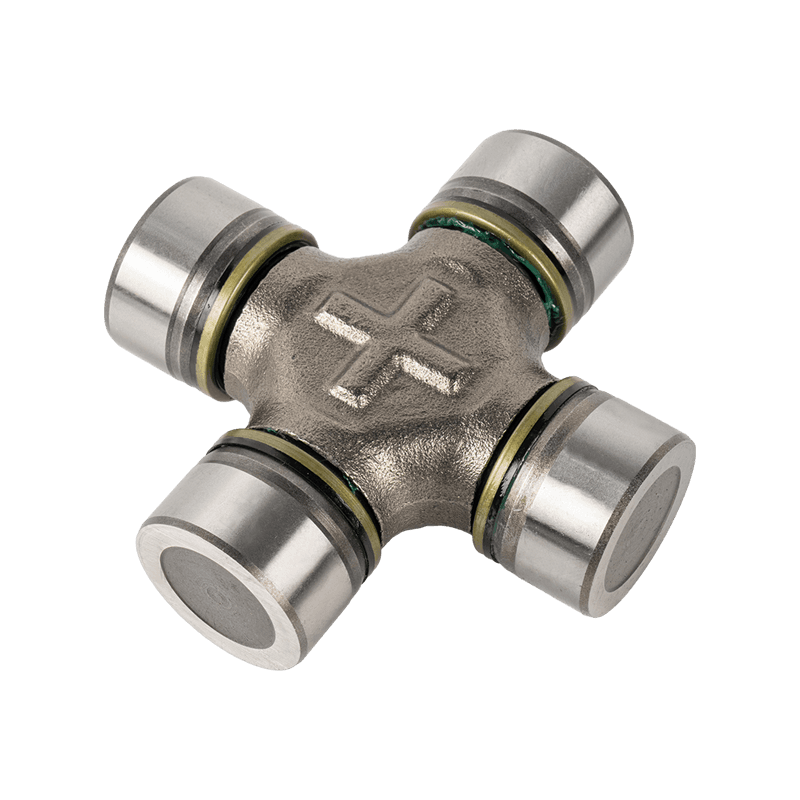

A U-joint, also known as a universal joint, is a mechanical component that allows for the transfer of rotary motion between two shafts that are not aligned with each other. It is commonly used in power transmission systems, such as the driveshafts of vehicles or heavy machinery. The U-joint consists of a cross-shaped component with four arms that connect the two shafts at an angle, enabling smooth transfer of power even when the shafts are at different angles.

In heavy equipment, U-joints are essential in transmitting power from the engine to various components, such as the wheels, axles, or tracks. The ability to maintain constant power flow while compensating for changes in angles and motion is what makes U-joints an indispensable part of heavy machinery.

The Role of Komatsu U-Joints in Heavy Equipment Performance

Komatsu U-joints are designed to provide precise and reliable power transmission, even in the harshest conditions. Here are some of the reasons why Komatsu U-joints are considered a key component in heavy equipment performance:

1. Power Transmission Efficiency

One of the primary functions of a U-joint is to transmit rotational power from one part of the machine to another. In heavy equipment, this power transmission must be efficient and reliable to ensure the machine operates smoothly. Komatsu U-joints are engineered to deliver high torque capacity, ensuring that the machinery can handle demanding tasks without losing performance.

Whether it’s powering the wheels of an excavator or transferring torque to a bulldozer's tracks, the Komatsu U-joint plays a vital role in ensuring the machine can function at full capacity. The seamless transmission of power helps reduce the chances of equipment failure, ensuring that the machine performs optimally throughout its operational lifespan.

2. Durability in Harsh Environments

Heavy equipment is often used in environments where the conditions are extreme, including rough terrain, high temperatures, and exposure to dirt, water, and chemicals. In these environments, components like U-joints must be able to withstand constant wear and tear.

Komatsu U-joints are manufactured using high-strength materials, including alloy steels and heat-treated components, which provide exceptional resistance to corrosion and wear. This ensures that the U-joints maintain their integrity and continue to perform efficiently over time, even in challenging environments. The durability of Komatsu U-joints extends the overall lifespan of the equipment, reducing the frequency of repairs or part replacements.

3. Flexibility and Smooth Operation

Komatsu U-joints are designed to maintain flexibility in power transmission while ensuring smooth and stable operation. Heavy equipment often operates under varying loads and at different angles, particularly when navigating rough terrain or working with uneven surfaces. The ability of the U-joint to maintain a consistent connection between the shafts, regardless of the angle, ensures that the power is transmitted smoothly, preventing vibration and unnecessary wear.

This smooth operation is especially important for maintaining the comfort and safety of the operator. Machines with faulty or worn-out U-joints can experience jerky movements, increased vibration, and reduced control, which can lead to operator fatigue and safety concerns. Komatsu U-joints, by contrast, are engineered for smooth, precise motion, making the equipment more comfortable and safer to operate.

4. Enhanced Load-Bearing Capacity

Komatsu U-joints are designed to handle high levels of torque and pressure, which are common in heavy-duty applications such as mining, construction, and forestry. These joints can absorb and distribute loads effectively, allowing the machine to handle intense operational demands without compromising performance.

The high load-bearing capacity of Komatsu U-joints ensures that equipment like dump trucks, bulldozers, and excavators can operate efficiently under heavy loads, which is essential for productivity and safety. When U-joints are made to handle substantial weight and stress, the equipment can perform its tasks without interruption, increasing both uptime and efficiency.

5. Reduced Maintenance Costs

Routine maintenance is essential to ensure that heavy machinery operates smoothly and efficiently. However, components like U-joints can become worn over time, leading to costly repairs or replacements. Komatsu U-joints are designed to have a longer lifespan, reducing the frequency of maintenance required. This not only helps lower maintenance costs but also minimizes downtime, allowing the machinery to stay in operation longer.

The reliability and durability of Komatsu U-joints also help prevent the need for premature replacement, which can be expensive for construction companies and other businesses relying on heavy equipment. By investing in high-quality, long-lasting U-joints, companies can reduce their overall maintenance budgets and improve the profitability of their operations.

6. Compatibility with a Wide Range of Equipment

Another advantage of Komatsu U-joints is their compatibility with a wide range of heavy equipment. Whether it’s a Komatsu excavator, a bulldozer, or a loader, Komatsu U-joints are designed to integrate seamlessly into various types of machinery. This versatility makes them a go-to option for construction and mining companies that operate a fleet of different equipment.

By standardizing on Komatsu U-joints across multiple machines, companies can simplify their inventory management and ensure that they always have the right parts available. This also makes it easier to maintain consistent performance across the entire fleet of equipment, reducing the complexity of repairs and replacement parts.

7. Improved Safety

Safety is a top priority for operators working with heavy machinery. A U-joint that fails or malfunctions can cause a sudden loss of power transmission, leading to an unexpected breakdown or even an accident. Komatsu U-joints are designed with safety in mind, as their smooth and reliable operation reduces the chances of sudden mechanical failures.

The durability and efficiency of Komatsu U-joints ensure that the equipment operates safely, reducing the likelihood of breakdowns or accidents caused by power loss. Additionally, the ability of Komatsu U-joints to maintain consistent performance under load and at various angles ensures that operators have better control of the machinery, enhancing safety on the job site.

8. Cost-Effective Performance

While Komatsu U-joints may come at a slightly higher initial cost than lower-quality alternatives, the value they provide in terms of durability, efficiency, and reduced maintenance costs makes them a cost-effective choice in the long run. By using Komatsu U-joints, companies can minimize downtime, reduce repair costs, and extend the lifespan of their machinery, which ultimately leads to better return on investment (ROI) for their equipment fleet.

Why Choose Komatsu U-Joints Over Competitors?

When it comes to heavy machinery, the reliability of components like U-joints is critical to the overall performance and longevity of the equipment. While there are many brands available on the market, Komatsu stands out due to its commitment to quality and innovation. Komatsu U-joints are known for their:

-

Superior materials: Using advanced alloys and heat-treated components to enhance strength and resistance to wear.

-

Precise engineering: Designed to deliver optimal power transmission with minimal vibration and reduced wear.

-

Long-term durability: Built to withstand harsh working conditions and extend the lifespan of the equipment.

-

Low maintenance requirements: Designed for extended use, reducing the need for frequent repairs or replacements.

Komatsu’s reputation for producing high-performance machinery extends to its U-joints, making them a preferred choice for many businesses in the construction, mining, and forestry industries.

English

English 中文简体

中文简体