How Industrial Equipment SGWB is Boosting Efficiency in Heavy Manufacturing

Content

- 1 Industrial Equipment Sgwb: Paving the Way for Automation in Heavy Manufacturing

- 2 Precision and Consistency: Improving Product Quality with SGWB Equipment

- 3 Minimizing Downtime with Predictive Maintenance Features

- 4 Optimizing Resource Usage and Reducing Waste

- 5 Enhancing Flexibility and Scalability

- 6 Data-Driven Insights for Continuous Improvement

- 7 Reducing Labor Costs and Improving Safety

The manufacturing industry is undergoing a major transformation, driven by the integration of advanced technologies that enhance productivity, improve quality, and optimize processes. Among these innovations, Industrial Equipment Sgwb is playing a crucial role in boosting efficiency within heavy manufacturing sectors. By leveraging cutting-edge machinery and automation solutions, SGWB equipment is helping manufacturers address long-standing challenges such as downtime, resource optimization, and precision control.

Industrial Equipment Sgwb: Paving the Way for Automation in Heavy Manufacturing

One of the most significant shifts in heavy manufacturing is the increasing reliance on automation. Industrial Equipment Sgwb is designed to support this transformation by integrating smart systems, robotics, and automated processes. From assembly lines to material handling, automation helps manufacturers streamline production and minimize human error.

For example, SGWB's automated robotic arms and conveyor systems have revolutionized material handling by increasing speed and reducing labor costs. These systems are equipped with sensors that detect potential issues before they cause delays, ensuring that production lines run smoothly and continuously.

By reducing manual interventions, SGWB equipment allows manufacturers to focus on more complex tasks, while the machines handle repetitive, time-consuming operations. This shift toward automation not only reduces operational costs but also increases throughput, enabling manufacturers to meet growing customer demands without compromising on quality.

Precision and Consistency: Improving Product Quality with SGWB Equipment

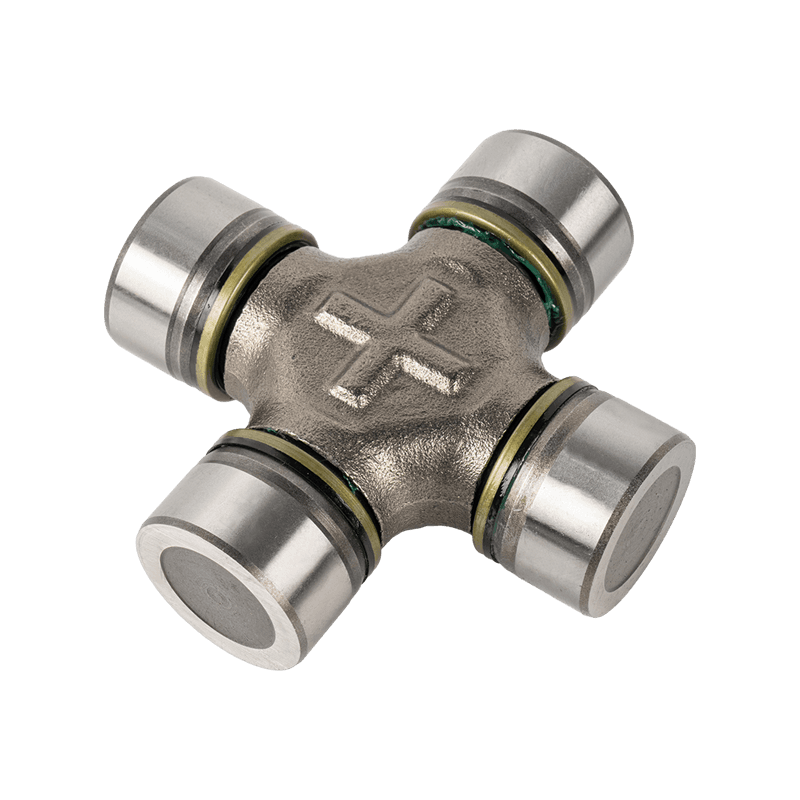

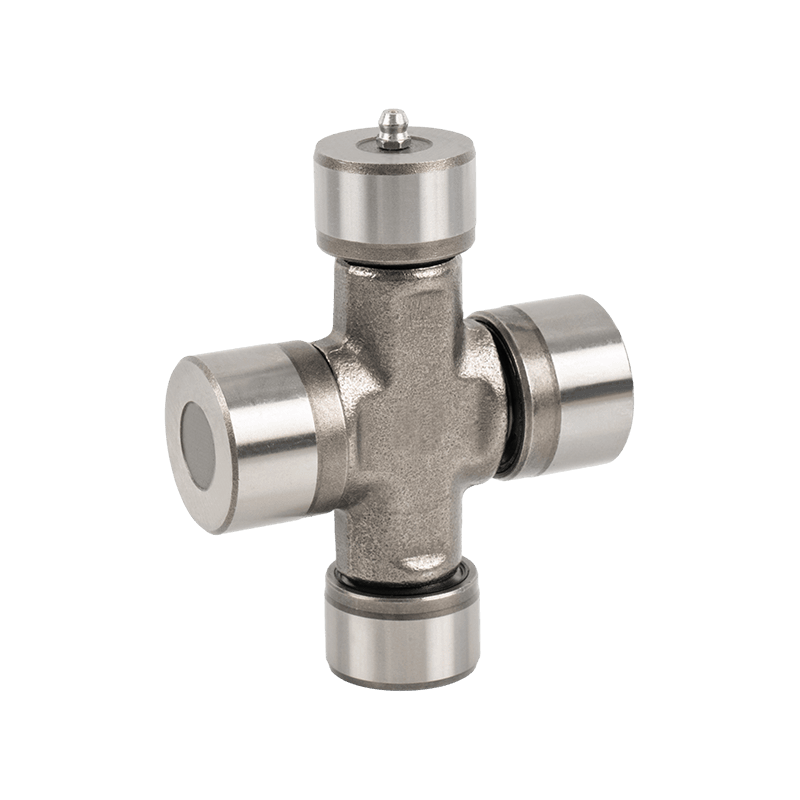

In industries like automotive, aerospace, and steel manufacturing, precision is paramount. Industrial Equipment Sgwb is built with state-of-the-art sensors and advanced software that enable manufacturers to achieve higher levels of accuracy in every step of the production process. This includes everything from component fabrication to assembly and testing.

For instance, SGWB’s CNC machines (Computer Numerical Control) and laser cutting systems are capable of producing components with unparalleled precision. These tools ensure that every part meets strict tolerances, reducing the need for rework and scrap. The result is a higher-quality end product with fewer defects, which directly contributes to improved operational efficiency and reduced material waste.

By enabling manufacturers to meet strict quality standards consistently, SGWB equipment ensures that they stay competitive in industries where quality control is critical to success.

Minimizing Downtime with Predictive Maintenance Features

Downtime is one of the biggest productivity killers in heavy manufacturing. Whether due to equipment failure or regular maintenance, unplanned downtime can lead to significant delays and revenue loss. Industrial Equipment Sgwb incorporates predictive maintenance capabilities, which use data analytics to anticipate potential failures before they happen.

With SGWB’s smart sensors and IoT-connected systems, equipment can continuously monitor its own performance, collecting data on variables such as temperature, pressure, and vibration. This data is then analyzed in real-time to identify any anomalies or signs of wear and tear that could lead to equipment failure.

By identifying issues early, SGWB equipment allows manufacturers to perform maintenance during off-peak hours, preventing unexpected breakdowns and minimizing production stoppages. Predictive maintenance not only helps extend the lifespan of machinery but also significantly reduces maintenance costs, further improving the overall efficiency of the manufacturing process.

Optimizing Resource Usage and Reducing Waste

Heavy manufacturing operations often deal with large amounts of raw materials, energy, and labor. Industrial Equipment Sgwb helps companies optimize resource usage and reduce waste through a combination of automation, real-time monitoring, and energy-efficient systems.

For example, SGWB’s energy-efficient motors and high-performance hydraulic systems reduce energy consumption by adjusting power levels based on real-time production needs. These energy-saving features help reduce operating costs while also promoting sustainable manufacturing practices.

Moreover, SGWB equipment is designed to optimize the usage of raw materials. By utilizing precise cutting, molding, and forming techniques, manufacturers can minimize material waste. Advanced quality control systems ensure that every part is produced to exact specifications, reducing the likelihood of defects and scrap.

Through these resource optimization strategies, Industrial Equipment Sgwb not only boosts productivity but also supports a more sustainable and cost-effective manufacturing process.

Enhancing Flexibility and Scalability

The modern manufacturing environment demands flexibility, as manufacturers must quickly adapt to changing market conditions, customer preferences, and production requirements. Industrial Equipment Sgwb provides manufacturers with the ability to scale their operations easily and make rapid adjustments to production processes.

SGWB’s modular equipment systems allow manufacturers to reconfigure their production lines to accommodate different product types or production volumes. This flexibility is particularly valuable in industries where product specifications change frequently or production volumes fluctuate.

For instance, in industries like automotive manufacturing, where product lines might shift from one vehicle model to another, SGWB’s modular production systems can be easily adapted to meet new requirements. This scalability enables manufacturers to remain competitive in a fast-paced market while reducing downtime between product changeovers.

Data-Driven Insights for Continuous Improvement

The use of big data and analytics is another way Industrial Equipment Sgwb enhances efficiency in heavy manufacturing. With integrated data collection and analysis tools, manufacturers gain real-time insights into key production metrics, such as cycle times, throughput, and defect rates.

SGWB equipment allows manufacturers to monitor every stage of the production process, collecting detailed performance data that can be analyzed to identify bottlenecks and inefficiencies. This data-driven approach enables manufacturers to implement continuous improvement initiatives, optimizing workflows, reducing cycle times, and improving overall operational efficiency.

Moreover, SGWB’s data-driven insights can inform decision-making, enabling manufacturers to make smarter investments in equipment upgrades, process improvements, and workforce training. By leveraging data to drive performance, manufacturers can foster a culture of continuous improvement that delivers long-term benefits.

Reducing Labor Costs and Improving Safety

Labor costs are a significant expense in heavy manufacturing, and with increasing labor shortages in some regions, manufacturers are turning to automation and industrial equipment to fill the gap. Industrial Equipment Sgwb helps reduce reliance on manual labor while also improving safety on the shop floor.

SGWB’s automated systems, such as robotic arms and conveyors, take over tasks that would otherwise require human labor, freeing up workers for more complex tasks that require skill and judgment. At the same time, these automated systems can handle hazardous tasks, such as heavy lifting or working with dangerous materials, reducing the risk of workplace injuries.

By improving both labor efficiency and workplace safety, SGWB equipment contributes to a more productive and safer manufacturing environment, which is crucial for long-term business success.

English

English 中文简体

中文简体