Why Cross Joints Are Critical for the Smooth Operation of Volvo, Scania, and Benz Vehicles

Content

- 1 What is a Cross Joint?

- 2 Ensuring Smooth Power Transmission

- 3 Adapting to Vehicle Suspension and Axle Flexing

- 4 Improved Durability and Longevity of Drivetrain Components

- 5 Enhanced Safety and Driving Comfort

- 6 Preventing Unnecessary Wear and Tear

- 7 Cross Joint Maintenance for Optimal Performance

- 8 Innovations in Cross Joint Technology

When it comes to heavy-duty vehicles, such as trucks and buses, maintaining a smooth and efficient operation is essential not only for performance but also for safety, reliability, and longevity. One often-overlooked yet crucial component that plays a significant role in the smooth functioning of these vehicles is the cross joint. Found in the driveline systems of many commercial vehicles, including those from top manufacturers like Volvo Scania Benz Cross Joint are vital for transmitting power effectively between different drivetrain components.

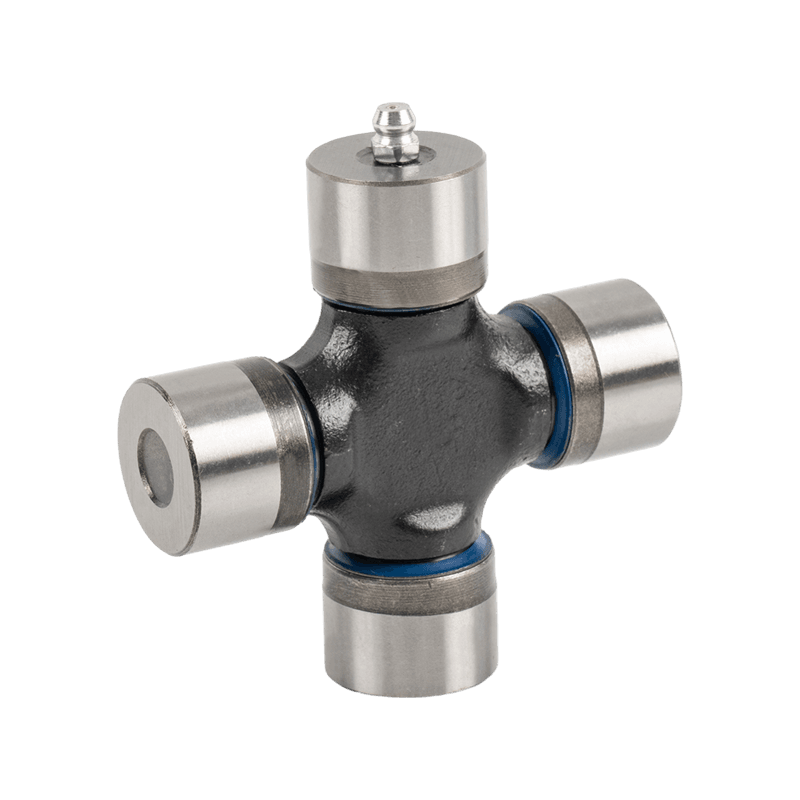

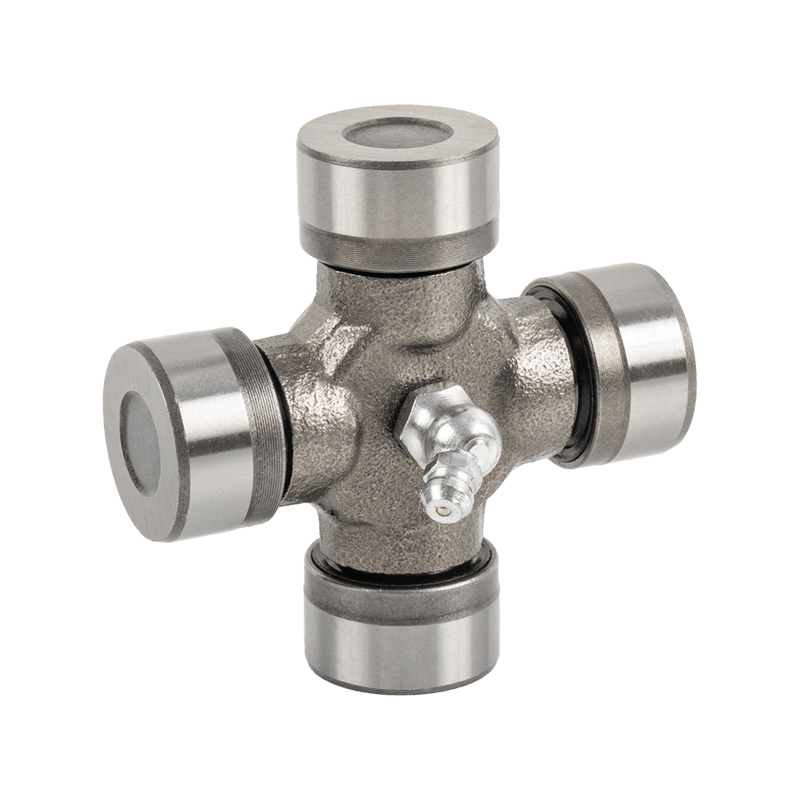

What is a Cross Joint?

A cross joint, often referred to as a universal joint (U-joint), is a critical component in the drivetrain of many vehicles, especially heavy-duty trucks and buses. It connects two rotating shafts while allowing them to transfer power even when they are at an angle to each other. In simple terms, it enables the smooth transmission of torque from the engine to the wheels, even when the vehicle’s suspension or axle systems are flexing.

Cross joints are usually located at the intersections of the driveshafts in commercial vehicles. These joints are designed to compensate for the up and down movement of the suspension while maintaining power transmission to the wheels. This flexibility is particularly essential in Volvo, Scania, and Benz vehicles, which often operate in rough terrains or under heavy load conditions.

Ensuring Smooth Power Transmission

One of the primary functions of cross joints in vehicles like Volvo, Scania, and Benz trucks is ensuring the smooth transmission of power from the engine to the wheels, especially when there are variations in the angle between rotating parts. When a vehicle moves, its drivetrain (which includes components like the driveshaft, axle, and transmission) needs to adjust to the continuous motion and flexing of the vehicle’s suspension.

In trucks, buses, and other heavy-duty vehicles, this constant movement would create stress on the drivetrain components. The cross joint ensures that power is transmitted seamlessly without interruption, reducing the chances of jarring movements or vibration, which could otherwise lead to increased wear and mechanical failure.

Adapting to Vehicle Suspension and Axle Flexing

Heavy-duty vehicles like Volvo trucks, Scania buses, and Benz commercial vehicles are often subjected to extreme conditions, including uneven roads, heavy cargo loads, and constant turning. These factors cause the suspension system to flex and the axles to change angles relative to the powertrain.

Cross joints are designed to adapt to these changing angles and help the driveshaft maintain continuous movement even when the suspension is compressed or extended. This ability to flex ensures that the vehicle can deliver power efficiently to the wheels despite the constant motion or shift in suspension, making cross joints an essential part of the drivetrain system in commercial vehicles.

Improved Durability and Longevity of Drivetrain Components

The durability of a vehicle’s drivetrain system largely depends on the quality and reliability of its cross joints. When cross joints are designed and maintained properly, they help distribute torque evenly across the driveshaft, reducing the stress placed on individual parts. This not only ensures that the vehicle performs optimally but also enhances the overall longevity of the drivetrain components.

For heavy-duty vehicles like Volvo, Scania, and Benz, the reliability of cross joints is critical. These vehicles are often subjected to high-mileage usage, harsh environments, and demanding workloads. Cross joints that are well-designed and well-maintained reduce the likelihood of costly repairs or component failures, saving vehicle owners money in the long term.

Enhanced Safety and Driving Comfort

Cross joints are crucial for maintaining vehicle safety. When cross joints wear out or fail, the vehicle's drivetrain becomes unstable, leading to potential vibrations, excessive noise, or erratic movements. This not only reduces the comfort of the ride but can also put the driver and other road users at risk.

In Volvo, Scania, and Benz vehicles, manufacturers invest heavily in cross joint technology to ensure smooth operation, contributing to safer driving experiences. A well-functioning cross joint helps prevent dangerous vibrations or jolts, offering a more comfortable and stable ride, particularly for long-haul truck drivers or passengers in buses who may be traveling for extended periods.

Preventing Unnecessary Wear and Tear

The wear and tear that a vehicle’s drivetrain system undergoes can be significant, especially for commercial vehicles that are constantly in operation. Without the proper functioning of cross joints, the powertrain would experience an uneven transfer of torque, leading to excessive wear on the driveshaft, transmission, and differential components. This could cause parts to degrade faster, resulting in more frequent repairs and downtime.

By absorbing the shock and vibration caused by the movement of the suspension, cross joints prevent undue strain on other drivetrain components. This helps extend the life of critical parts in Volvo, Scania, and Benz vehicles, reducing maintenance costs and increasing the overall efficiency of the vehicle.

Cross Joint Maintenance for Optimal Performance

Regular maintenance of cross joints is crucial for their optimal performance. For Volvo, Scania, and Benz vehicles, manufacturers often recommend routine inspections and lubrication of cross joints to prevent dirt or debris from entering the joints and causing premature wear. In extreme conditions, cross joints can wear out faster, so it is essential to monitor them closely, particularly for vehicles that operate in harsh environments or at high mileage.

Keeping the cross joints properly lubricated and ensuring they remain free of contaminants can go a long way in preventing premature failure and ensuring the long-term performance of the drivetrain system.

Innovations in Cross Joint Technology

Over the years, advancements in cross joint technology have made them more durable, efficient, and adaptable to the increasing demands of modern vehicles. Volvo, Scania, and Benz have embraced these innovations by utilizing high-strength materials and improved engineering techniques to enhance the performance of their cross joints.

For example, self-lubricating cross joints and sealed bearings are now common in many of these vehicles, reducing the need for regular maintenance while improving the overall lifespan of the parts. These innovations ensure that the vehicles continue to perform optimally, even under the most challenging operating conditions.

English

English 中文简体

中文简体