How Heavy Trucks Universal Joints Contribute to the Efficiency of Long Haul Trucks

Content

Long haul trucking is a critical component of the global transportation network. From carrying goods across cities to delivering supplies over vast distances, long haul trucks keep the economy moving. The efficiency of these trucks directly impacts fuel costs, maintenance expenses, and overall operational productivity. One of the most important yet often overlooked components that contribute to the efficiency of long haul trucks is the Heavy Trucks Universal Joint.

The Heavy Trucks Universal Joint plays a vital role in the truck’s drivetrain system, helping to ensure smooth power transfer between the engine and wheels, even under challenging conditions.

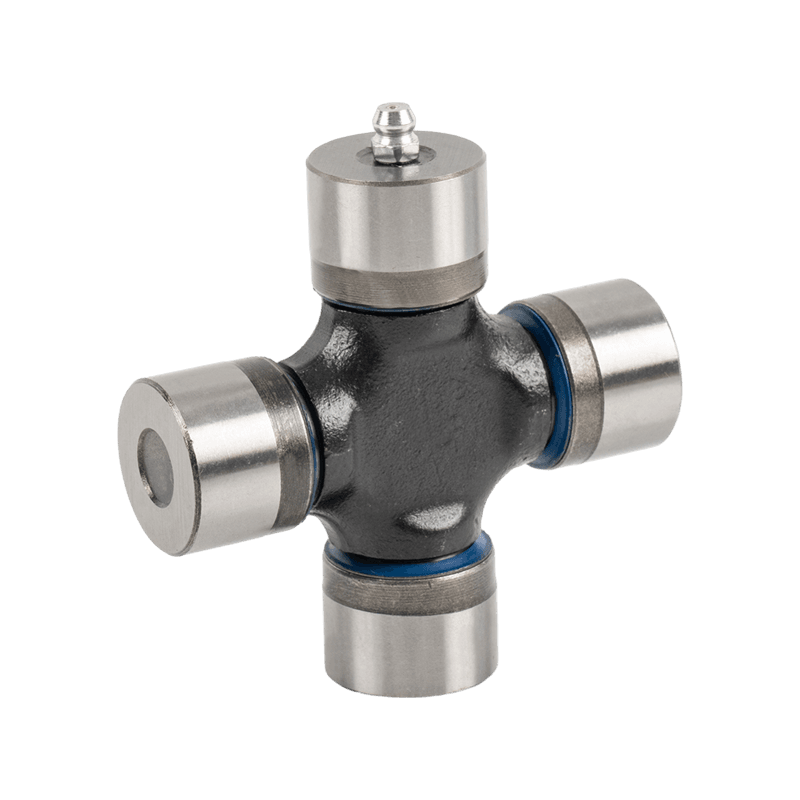

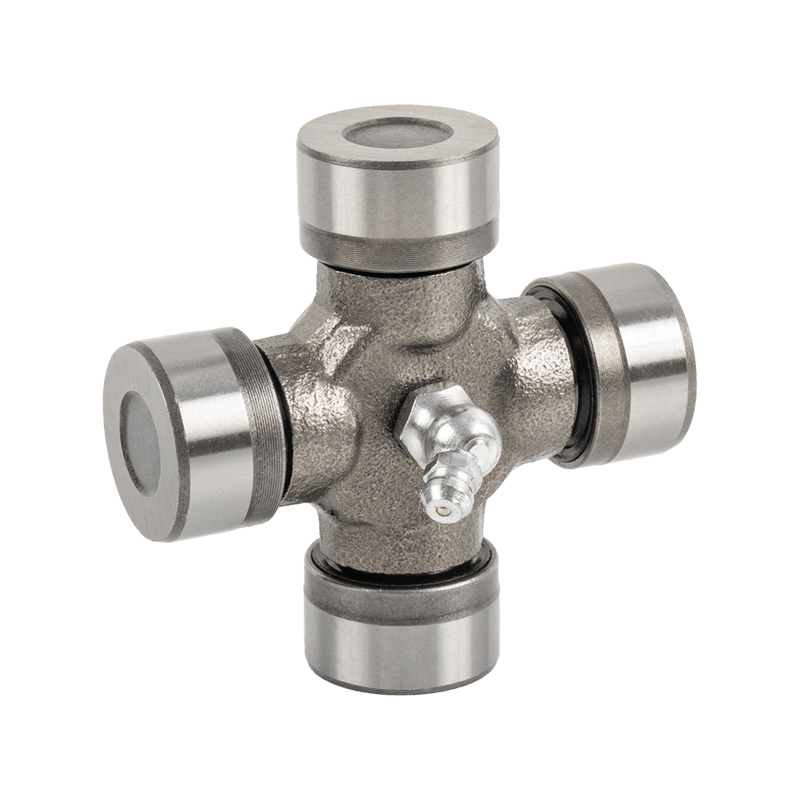

What Is a Heavy Trucks Universal Joint?

A Heavy Trucks Universal Joint, or U-joint, is a mechanical component used to transmit rotary motion and torque between two shafts that are not in a straight line. It is an essential part of a truck's drivetrain, connecting the driveshaft to the axles and allowing the engine’s power to be transferred efficiently to the wheels.

In long haul trucks, the Heavy Trucks Universal Joint compensates for the changing angles that occur due to the movement of the truck’s suspension system. The suspension absorbs bumps and road irregularities, which can cause changes in the angle of the driveshaft. The U-joint allows the driveshaft to rotate smoothly while adjusting to these changes, ensuring continuous power transmission. Without a functioning U-joint, the drivetrain would experience vibrations, misalignment, and potential failure.

How Heavy Trucks Universal Joints Contribute to Truck Efficiency

Smooth Power Transfer for Consistent Performance

The Heavy Trucks Universal Joint is responsible for ensuring that power generated by the engine is smoothly transferred to the wheels. In long haul trucking, where vehicles are expected to travel thousands of miles, smooth power transfer is crucial. When the U-joint functions correctly, the truck experiences less strain, and power is delivered efficiently to the wheels, allowing the truck to maintain a steady speed and avoid performance issues such as hesitation or jerking.

A malfunctioning Heavy Trucks Universal Joint can cause disruptions in power delivery, leading to a bumpy ride and increased fuel consumption. On the other hand, a well-maintained U-joint ensures that the engine’s output is optimally transferred to the wheels, resulting in a smoother ride and better overall performance.

Compensating for Suspension Movement

The suspension system of a truck helps to absorb shocks from rough roads, uneven terrain, and bumps. However, this movement can cause the driveshaft to shift angles as the truck’s chassis moves. The Heavy Trucks Universal Joint compensates for these angle changes by allowing the driveshaft to rotate while adjusting to the varying angles caused by the suspension. This function ensures that power is continuously transmitted from the engine to the wheels without disruption, even as the truck’s suspension system moves in response to the road conditions.

In long haul trucking, where trucks often face variable road conditions over long distances, the Heavy Trucks Universal Joint plays a crucial role in ensuring that power transmission remains stable, regardless of the movement of the truck's chassis. This results in a more comfortable ride for the driver and a more efficient operation overall.

Enhancing Fuel Efficiency

Fuel efficiency is a major concern for long haul trucking companies, as fuel is one of the highest ongoing costs for any fleet. A smooth and efficient power transfer system, made possible by the Heavy Trucks Universal Joint, plays an indirect yet significant role in improving fuel efficiency. When the U-joint is in good condition, the engine operates more efficiently, transferring power to the wheels with minimal loss.

Conversely, a worn-out or damaged U-joint can cause friction and misalignment in the drivetrain, leading to higher energy consumption and reduced fuel economy. By ensuring that the Heavy Trucks Universal Joint is regularly maintained and functioning properly, trucking companies can improve fuel efficiency, reducing costs and increasing profitability over the long term.

Reducing Wear and Tear on Other Drivetrain Components

Long haul trucks are subjected to continuous stress and heavy usage, especially when driving long distances or carrying heavy loads. The drivetrain, including the Heavy Trucks Universal Joint, plays a critical role in transmitting power smoothly and preventing undue stress on other components, such as the transmission and axle bearings. A malfunctioning U-joint can lead to increased strain on the drivetrain, causing premature wear and tear on these other critical components.

By ensuring that the Heavy Trucks Universal Joint is in good condition, trucking companies can minimize the risk of damage to other parts of the drivetrain. This reduces the need for costly repairs or replacements and helps maintain the truck’s overall efficiency.

Improving Vehicle Handling and Driver Comfort

A well-maintained Heavy Trucks Universal Joint contributes to better vehicle handling, particularly when navigating rough or uneven roads. Without proper U-joint function, trucks can experience vibrations, noises, and jerking motions, making the ride uncomfortable for the driver. In extreme cases, a malfunctioning U-joint can even cause the driveshaft to fail, leading to a complete loss of power.

With a properly functioning U-joint, the truck’s drivetrain remains aligned, and vibrations are minimized. This results in better handling and a smoother ride for the driver, reducing driver fatigue during long trips and improving overall safety. Comfortable, smooth handling also contributes to more precise control over the truck, which is crucial for managing tight turns or navigating difficult terrain during long hauls.

Maintenance of Heavy Trucks Universal Joints for Optimal Efficiency

The Heavy Trucks Universal Joint is a durable component, but like all mechanical parts, it requires regular maintenance to perform at its best. Proper maintenance not only ensures the efficiency of the U-joint but also extends the lifespan of the truck’s entire drivetrain. Here are some tips for maintaining Heavy Trucks Universal Joints:

- Regular Inspections: The U-joint should be inspected periodically for signs of wear and tear, including rust, cracks, or damage to the U-joint's needle bearings. Regular inspections can help identify potential problems before they lead to significant failures.

- Lubrication: The U-joint relies on proper lubrication to reduce friction and prevent premature wear. Lack of lubrication can cause the U-joint to wear out quickly, leading to higher repair costs. Ensure that the U-joint is lubricated according to the manufacturer’s guidelines to keep it functioning smoothly.

- Proper Alignment: Misalignment of the U-joint can cause vibrations and reduce drivetrain efficiency. Ensure that the U-joint is properly aligned with the driveshaft and axles to ensure smooth power transfer and minimize unnecessary strain on the components.

- Choosing High-Quality U-Joints: Investing in high-quality Heavy Trucks Universal Joints made from durable materials can greatly enhance the longevity and performance of the truck’s drivetrain. Quality U-joints can withstand heavy loads and harsh road conditions, contributing to the overall efficiency of the truck.

- Replacement When Necessary: Over time, even the best-maintained U-joints will eventually wear out. If you notice excessive vibrations, unusual noises, or difficulty in power transfer, it may be time to replace the U-joint to prevent further damage to the drivetrain.

English

English 中文简体

中文简体