U-Joint with 4 Plain Round Bearings Reduces Vibration and Wear in Drive Systems

Content

- 1 Understanding the Role of a Universal Joint

- 2 How Vibration Affects Drive Systems

- 3 Advantages of U-Joint with 4 Plain Round Bearings

- 4 Automotive Applications

- 5 Industrial Machinery Applications

- 6 Agricultural and Heavy Equipment Applications

- 7 Manufacturing Considerations

- 8 Market Trends and Demand Drivers

- 9 Choosing the Right U-Joint with 4 Plain Round Bearings

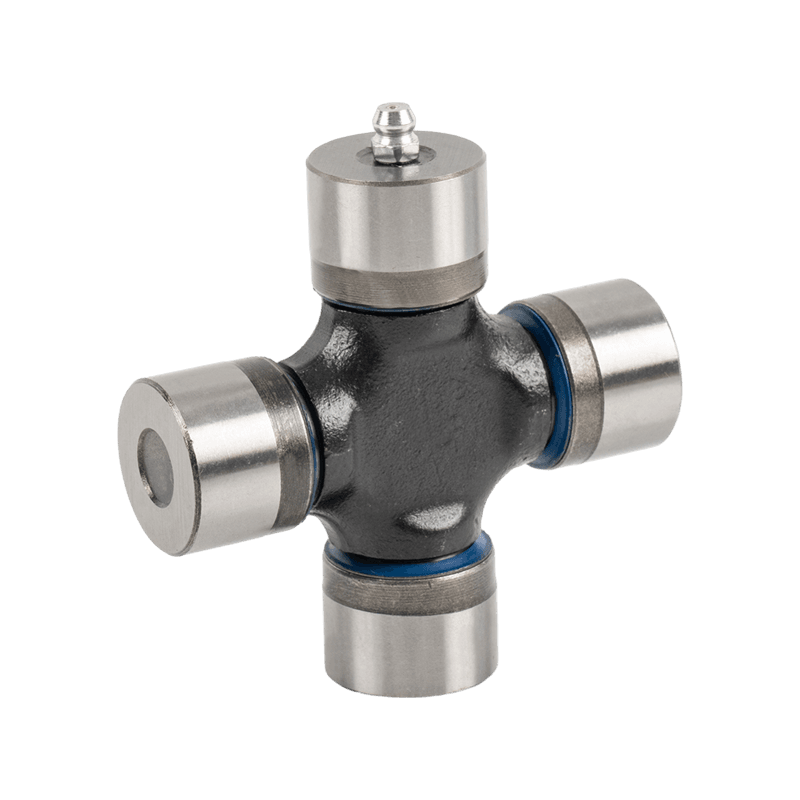

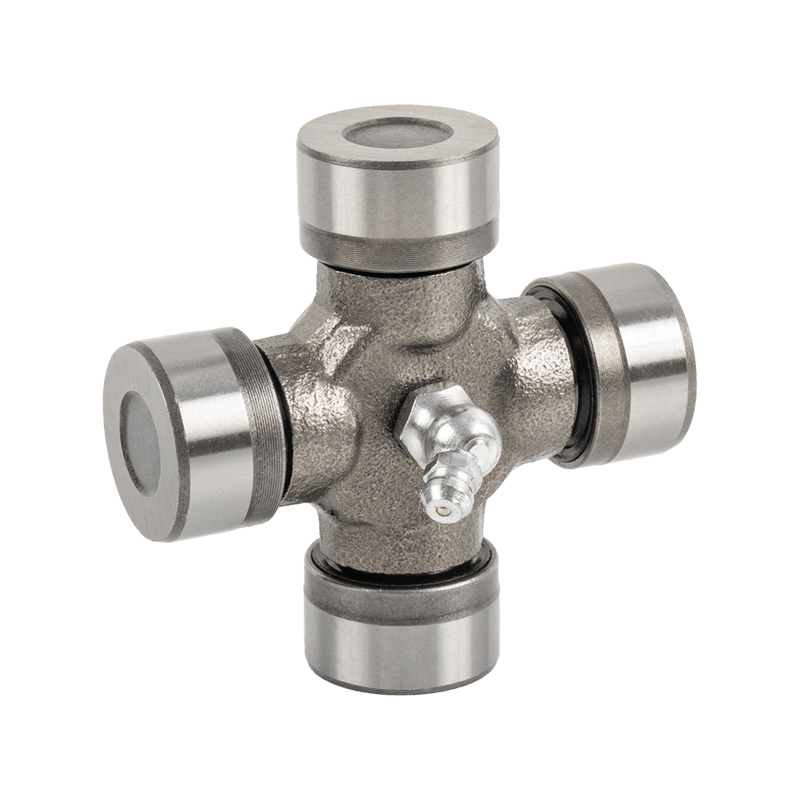

In modern mechanical systems, the efficiency and longevity of rotating equipment heavily depend on the quality and design of power transmission components. One critical part that plays a pivotal role in smooth and reliable operation is the universal joint, or U-joint. Among the many designs available, the U-Joint with 4 Plain Round Bearings has emerged as a preferred choice for engineers, OEMs, and industrial operators seeking to minimize vibration, reduce wear, and extend the service life of their drive systems.

As a leading manufacturer and supplier of U-Joints with 4 Plain Round Bearings, we have observed significant growth in global demand. From automotive drivelines to industrial machinery, this specific type of U-joint provides unparalleled reliability, making it an indispensable component in both heavy-duty and precision applications.

Understanding the Role of a Universal Joint

A universal joint (U-joint) is a mechanical device that allows rotational power to be transmitted between two shafts that are not perfectly aligned. In many drive systems, shafts may be connected at angles due to design constraints or moving components. U-joints accommodate this misalignment while maintaining continuous torque transfer.

The U-Joint with 4 Plain Round Bearings differs from standard cross-style joints or needle-bearing designs by incorporating four plain round bearings at each connection point. This design offers several advantages:

- Reduced friction and wear: Plain round bearings allow smooth rotational movement without the complex rolling elements that can wear unevenly.

- Lower vibration levels: Properly balanced bearings dampen torsional vibration, reducing stress on surrounding components.

- Enhanced durability: Fewer moving parts in the bearing assembly translate to fewer points of failure and longer service life.

How Vibration Affects Drive Systems

Vibration is one of the most significant contributors to wear and failure in drive systems. Excessive vibration can lead to:

- Premature bearing failure

- Shaft misalignment

- Gear and coupling damage

- Noise and operator discomfort

- Reduced efficiency and energy loss

In industrial machinery, construction vehicles, and automotive drivetrains, uncontrolled vibration can compromise both safety and productivity. The U-Joint with 4 Plain Round Bearings addresses these challenges by providing a smoother, more consistent transfer of torque even under variable loads.

Advantages of U-Joint with 4 Plain Round Bearings

Vibration Reduction

One of the primary benefits of the U-Joint with 4 Plain Round Bearings is its ability to reduce vibration throughout the drive system. The plain bearings provide uniform contact surfaces that absorb minor misalignments and prevent torsional shocks from being transmitted to connected components.

Reduced vibration translates into:

- Longer lifespan for connected shafts and gears

- Lower maintenance costs due to fewer replacements

- Quieter operation, which is particularly important in passenger vehicles and industrial settings

Minimized Wear

Wear occurs when friction, misalignment, or overload stresses parts of a drive system. By incorporating four plain round bearings, these U-joints distribute load evenly across the joint, reducing localized stress points.

Benefits include:

- Prolonged bearing and cross component life

- Consistent performance over long operating hours

- Lower risk of sudden failures in critical applications

High Load Capacity

Despite their simplicity, U-Joints with 4 Plain Round Bearings are capable of handling substantial torque loads. This makes them suitable for applications ranging from light-duty passenger cars to heavy-duty construction and agricultural machinery.

Key advantages include:

- Ability to transmit high torque without deformation

- Suitable for fluctuating or shock loads

- Compatibility with both high-speed and low-speed drive systems

Versatility Across Applications

The U-Joint with 4 Plain Round Bearings is versatile, making it suitable for multiple industries and use cases:

- Automotive: Passenger vehicles, trucks, SUVs, and off-road vehicles

- Construction and Mining Equipment: Excavators, loaders, bulldozers, and cranes

- Agriculture: Tractors, harvesters, and PTO-driven implements

- Industrial Machinery: Conveyors, mixers, and rotating equipment in factories

- Marine Applications: Boats and ships requiring durable drivetrain solutions

This versatility contributes to the growing demand from both OEMs and aftermarket distributors.

Automotive Applications

In automotive drivetrains, U-joints connect the transmission to the driveshaft or driveshaft to the differential, accommodating suspension movement and shaft misalignment. The U-Joint with 4 Plain Round Bearings is particularly effective in:

- Reducing driveline vibration, resulting in smoother rides

- Minimizing wear on driveshaft components, prolonging service life

- Handling high torque loads in heavy-duty trucks and SUVs

High-performance vehicles also benefit from these U-joints due to their consistent torque transfer and precision balancing, which improve acceleration and handling characteristics.

Industrial Machinery Applications

Industrial equipment often operates under harsh conditions, including heavy loads, dust, and variable speeds. U-Joints with 4 Plain Round Bearings excel in these environments by:

- Withstanding high torque and angular misalignment

- Reducing downtime caused by premature component wear

- Ensuring reliable operation in continuous-duty applications

From material handling systems to automated production lines, these U-joints help maintain efficiency and reduce maintenance costs.

Agricultural and Heavy Equipment Applications

In agriculture and construction, machines like tractors, harvesters, and excavators rely on U-joints for PTO shafts and hydraulic drives. The U-Joint with 4 Plain Round Bearings provides:

- High durability in outdoor, abrasive environments

- Resistance to shock loads from uneven terrain

- Reliable torque transfer even in high-load, low-speed operations

For operators, this means reduced risk of equipment failure during critical operations, saving both time and money.

Manufacturing Considerations

Producing high-quality U-Joints with 4 Plain Round Bearings requires precision engineering and strict quality control. Key manufacturing considerations include:

- Material Selection: High-strength alloy steel or heat-treated metals for cross components and bearing races ensure long-term durability.

- Precision Machining: CNC-machined surfaces and tight tolerances guarantee smooth operation and consistent performance.

- Surface Treatment: Coatings such as nitriding, phosphating, or specialized lubricants enhance wear resistance and corrosion protection.

- Assembly and Testing: Each U-joint undergoes torque, load, and vibration testing to meet OEM and industrial standards.

By maintaining these standards, manufacturers ensure that U-Joints with 4 Plain Round Bearings deliver reliable, long-lasting performance in all applications.

Market Trends and Demand Drivers

Several trends are contributing to the increased adoption of U-Joints with 4 Plain Round Bearings:

- Growth in Automotive Production: Rising global vehicle production, especially in emerging markets, increases demand for high-quality driveline components.

- Industrial Automation: Factories and processing plants increasingly rely on rotating machinery requiring precise and durable U-joints.

- Heavy Equipment Expansion: Construction, mining, and agricultural sectors demand robust U-joints capable of withstanding high torque and misalignment.

- Maintenance and Replacement Cycles: Aging fleets and industrial machinery create a steady market for replacement U-joints.

- Efficiency and Reliability Focus: OEMs and operators prioritize components that reduce vibration, wear, and downtime, improving productivity.

These trends indicate that the U-Joint with 4 Plain Round Bearings will continue to see strong global demand.

Choosing the Right U-Joint with 4 Plain Round Bearings

For OEMs, distributors, and end-users, selecting the right U-joint involves several key considerations:

- Torque Rating: Ensure the U-joint can handle the maximum operating torque of the application.

- Angular Capacity: Check the maximum operating angle the U-joint can accommodate.

- Bearing Material and Quality: High-quality plain round bearings reduce wear and maintenance.

- Compatibility: Match the U-joint dimensions and splines with the connected shafts.

- Operational Environment: Consider factors like temperature, dust, moisture, and shock loads.

Selecting the correct U-Joint with 4 Plain Round Bearings ensures optimal performance, longevity, and reduced maintenance.

English

English 中文简体

中文简体