How to Choose the Right Back Groove Round Bearings U-Joint for Your Projects

Content

When working on engineering or mechanical projects, selecting the right components is crucial for ensuring durability, performance, and efficiency. Among the many components you might encounter, Back Groove Round Bearings U-Joints stand out for their versatility and critical role in various industrial applications. Whether you're designing a vehicle, machinery, or even custom equipment, understanding how to choose the right Back Groove Round Bearings U-Joint can make a significant difference in the success of your project.

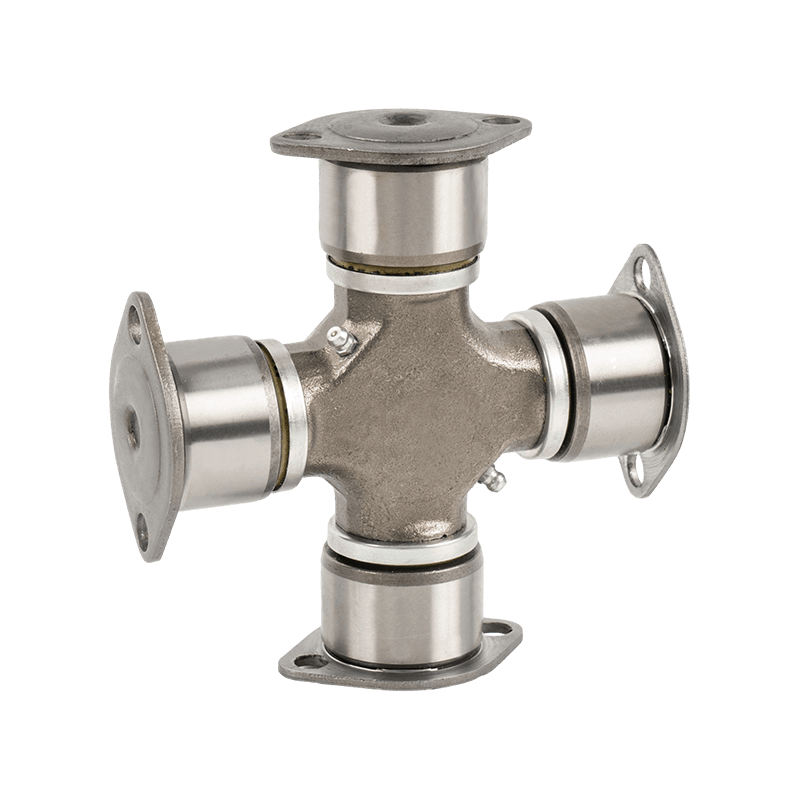

What Are Back Groove Round Bearings U-Joints?

Before diving into how to choose the right one, let's first understand what a Back Groove Round Bearings U-Joint is.

Back Groove Round Bearings:

Back Groove Round Bearings are a specific type of bearing designed to support rotational movement and reduce friction. They consist of an inner and outer race, with a set of rolling elements, such as balls or rollers, placed between them. These bearings are often used in applications requiring smooth rotation and minimal wear, such as automotive parts, industrial machinery, and even robotics.

U-Joint:

A U-Joint, or universal joint, is a mechanical device that connects two shafts at an angle. It allows for the transfer of rotational motion between the two shafts, even if they are not aligned. U-Joints are crucial in many mechanical systems, including vehicles, where they help transmit power from the engine to the wheels or other parts.

The "Back Groove" refers to a groove machined into the bearing that helps it stay securely in place and maintain alignment with the U-Joint. This ensures that the bearing can handle the stresses placed on it during operation, leading to longer life and better overall performance.

Key Features of Back Groove Round Bearings U-Joints

When it comes to selecting the right Back Groove Round Bearings U-Joint for your project, understanding their key features can help you make an informed decision. Here are some aspects to consider:

Durability

Back Groove Round Bearings U-Joints are designed for heavy-duty applications, which require parts that can withstand significant loads and forces. This makes them ideal for industries such as automotive, aerospace, and industrial machinery. The back groove feature helps distribute these loads more evenly, preventing wear and tear on the bearing and U-Joint components.

Precision and Performance

High-performance applications demand precise control of motion and minimal friction. Back Groove Round Bearings U-Joints excel in applications that require smooth rotational movement and consistent power transmission. The back groove also helps maintain the alignment of the bearing, enhancing the overall performance of the system.

Corrosion Resistance

Depending on the material used for the bearing and U-Joint, some models come with corrosion-resistant coatings or are made from materials like stainless steel, making them suitable for outdoor or high-humidity environments. This feature is particularly important for vehicles and machinery exposed to weather conditions or harsh chemicals.

Versatility

Back Groove Round Bearings U-Joints are versatile and can be used in various industries. From automotive driveshafts to heavy machinery and robotic arms, they provide essential support where motion is required between non-aligned shafts.

Factors to Consider When Choosing the Right Back Groove Round Bearings U-Joint

Choosing the right Back Groove Round Bearings U-Joint for your project involves considering several important factors. Let’s walk through these aspects to help guide your decision-making process.

Application Type

The first factor to consider is the specific application you need the Back Groove Round Bearings U-Joint for. The operating conditions of the project will influence the selection of materials and features. For instance:

- Automotive Applications: In vehicles, Back Groove Round Bearings U-Joints are often used in the drivetrain system, connecting the driveshaft to the wheels. In these cases, you will need a U-Joint that can handle high-speed rotation and constant stress.

- Heavy Machinery: For machinery in industries like mining or construction, the U-Joint must be designed to withstand high torque and heavy loads.

- Robotics and Precision Engineering: In these applications, precision and minimal wear are paramount. You'll need a U-Joint that offers smooth movement and has a low friction coefficient.

Load Capacity

Each U-Joint has a specific load capacity, which defines how much weight and force it can support without compromising performance. When selecting the right U-Joint for your project, it’s crucial to understand the maximum loads the component will experience during operation.

- Dynamic Load: The loads experienced by the U-Joint during normal operation. These can be impacted by speed, weight, and other dynamic factors.

- Static Load: The loads that the U-Joint will support when the system is stationary or not in motion.

Ensuring that the U-Joint can handle both types of loads will help prevent premature failure and ensure the longevity of your system.

Size and Fit

The size and fit of the U-Joint are crucial to ensuring that it works as expected. Incorrectly sized U-Joints can cause misalignment, increased wear, and eventually failure of the mechanical system.

Make sure to measure the shaft diameters and other components where the U-Joint will be installed. The U-Joint should fit snugly without any excessive play or tightness.

Material Selection

The material of the Back Groove Round Bearings U-Joint affects its strength, corrosion resistance, and overall performance. Common materials include:

- Stainless Steel: Known for its strength and resistance to corrosion, stainless steel is often used in high-performance applications.

- Alloy Steel: Provides increased strength and durability, making it suitable for heavy-duty applications.

- Carbon Steel: Typically used in applications where cost is a major factor and where the environment is less demanding.

When choosing a material, consider the environment in which the U-Joint will operate, including exposure to chemicals, heat, or moisture.

Lubrication and Maintenance

U-Joints often require lubrication to reduce friction and wear. Some U-Joints come with grease fittings or sealed designs to retain lubricant longer. When selecting a Back Groove Round Bearings U-Joint, check whether the design includes features for easy maintenance and lubrication. In industrial applications, regular lubrication ensures that the U-Joint operates efficiently over time.

Angle and Rotation Range

The U-Joint's ability to handle angle variations and rotational movement is another critical factor. U-Joints in vehicles, for example, need to handle varying angles as the vehicle moves, while industrial machinery might require a constant rotation at a fixed angle.

When choosing a U-Joint, ensure it can accommodate the necessary angles and rotation range that your application demands.

Cost and Availability

While quality and durability should be the main focus, cost is often a consideration in any project. The price of Back Groove Round Bearings U-Joints can vary depending on factors like material, size, and load capacity. Consider your budget, but avoid opting for cheaper components that may not meet your performance standards. Similarly, check the availability of replacement parts and the supplier’s support.

How to Properly Install Back Groove Round Bearings U-Joint

After selecting the right Back Groove Round Bearings U-Joint for your project, it’s important to install it correctly to ensure proper functioning. Installation involves securing the U-Joint in place and ensuring that it’s aligned with the shafts.

Here are some general tips for installation:

- Inspect the U-Joint: Before installation, ensure that the U-Joint is free of defects and properly lubricated.

- Align the Components: Proper alignment of the U-Joint with the shafts is essential for preventing uneven wear and ensuring smooth operation.

- Secure the U-Joint: Use appropriate fasteners or retaining clips to secure the U-Joint in place, following the manufacturer’s specifications.

- Lubricate Regularly: Regular lubrication will help reduce friction and extend the life of the U-Joint.

English

English 中文简体

中文简体