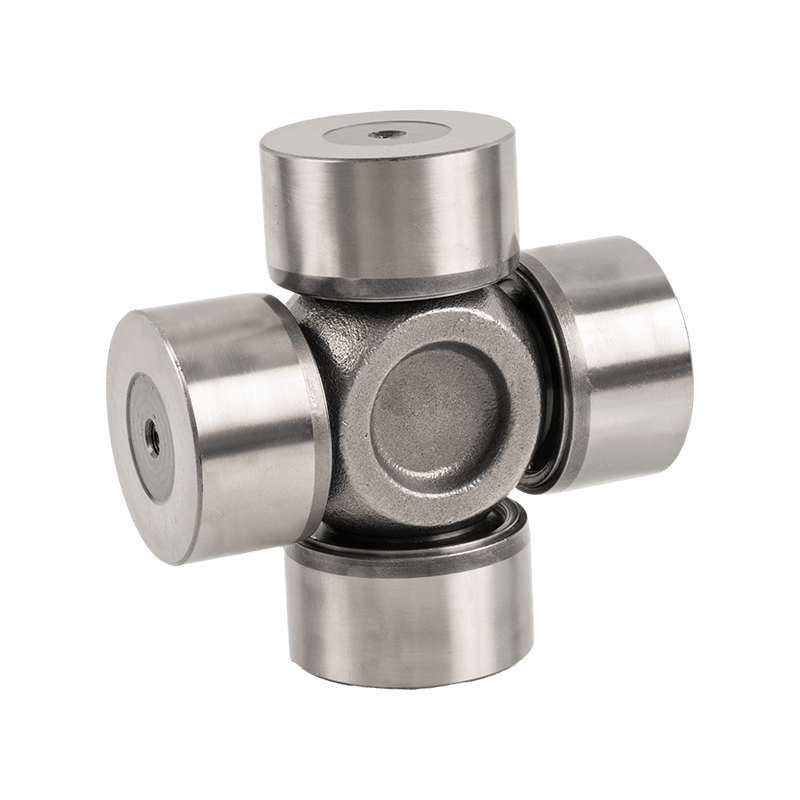

High-quality circular bearing U-joints to meet global market needs

The cross and cup parts of this 4 plain round bearings U-joint are made of a variety of high-quality alloy steels, including 20 chrome alloy steel, 20CrMnTi, 20CrMo, 8622H, 8620, SCM415, DC04, SPCC, GR15, 15CrMo, etc., to ensure its good performance under high load and many working environments. The diversity of materials allows the product to provide different performance according to customer needs, such as higher compressive strength, better wear resistance and longer service life.

The U-joint components are made of high-strength materials such as 65Mn and ZQ235 to ensure the firmness and durability of the product. 65Mn is a high-strength alloy steel, which is usually used to manufacture mechanical parts that require high toughness and high wear resistance. After proper heat treatment, the material can achieve a higher hardness, so that the product maintains good wear resistance and compression resistance under high-load working conditions, and is particularly suitable for occasions subject to frequent impact and friction. Although the 65Mn material has a high hardness, it can still maintain good toughness. This makes the U-joint less prone to brittle fracture under high impact, able to withstand external impact and extend its service life. The strong wear resistance of 65Mn enables the U-joint to be used in high friction environments, such as mechanical transmission systems and vehicles, ensuring efficient connection performance for a long time. ZQ235 is a carbon steel material with good plasticity and weldability, and is usually used to manufacture structural parts that require high strength and good corrosion resistance. ZQ235 material has good welding performance, which is convenient for processing and manufacturing joint parts of complex shapes. This is crucial for the production of U-joints, ensuring that each joint is connected reliably and without defects. Although ZQ235 is carbon steel, it can have strong corrosion resistance through proper surface treatment. This allows the U-joint to maintain a long service life when exposed to humid environments or in contact with corrosive fluids. ZQ235 material can still maintain good strength and stability under high temperature conditions, which is particularly important for U-joints in high temperature working environments, ensuring that it is still not easy to deform or damage at high temperatures.

The hardness range of LB circular bearing U-joint is 58-64HRC, ensuring good wear resistance and stability. All products have passed the IATF 16949 quality management system certification and meet the international automotive industry quality standards, ensuring that each set of products is manufactured under high-standard production processes. Products are strictly produced in accordance with international standards such as DIN, ANSI/ASME, BS, GB, JIS, etc., and non-standard customization services can be provided according to customer requirements to meet the needs of various markets around the world.

In order to meet the needs of different markets, the LB brand provides a variety of color coating options, including bright, black coating, phosphating coating, etc. These coatings can not only enhance the appearance of the product, but also enhance its corrosion resistance and extend the service life of the product, especially suitable for use in harsh environments.

The production capacity of LB brand circular bearing U-joint is very strong, which can meet the supply demand of 600,000 to 800,000 sets per month. The common order quantity is 500 to 2,000 sets, and different delivery methods are supported, including FOB, CIF, CNF, EXW, etc., which is convenient for customers to choose the suitable logistics solution. Delivery ports include major ports such as Shanghai, Ningbo, and Guangzhou, ensuring timely delivery worldwide. In terms of packaging, the LB brand provides a variety of options such as natural packaging, color packaging, and wooden pallet packaging to ensure the safety and integrity of the product during transportation.

English

English 中文简体

中文简体