Key Applications of Russia Cross Joint in Oil and Gas Pipelines

With the continuous growth of global energy demand, the oil and gas industry, as an important foundation for the operation of modern society, has become particularly critical in terms of the safety and efficiency of its infrastructure construction and maintenance. Pipelines are the main way to transport oil and gas, and the quality of their connectors directly affects the operating safety and efficiency of the entire system. In recent years, Russia Cross Joint has become an indispensable key component in oil and gas pipeline systems with its unique structural advantages and performance, and is widely used in complex terrain and harsh environments.

Oil and gas pipelines usually need to cross complex geological terrains, including permafrost, mountainous areas, deserts, seabeds and other environments, and pipelines need to withstand various temperatures, pressures and chemical corrosion tests. The connection part is the part of the pipeline system that is prone to safety hazards. Any improper connection or material defects may cause leakage, rupture, and even cause serious accidents. With the improvement of the energy industry's requirements for transportation efficiency and environmental protection, pipeline connectors must not only ensure absolute sealing and strength, but also be easy to install and maintain. The traditional straight-line connection method is limited by its single structure, complex installation and stress concentration, and it is difficult to meet the diverse needs of modern pipeline engineering.

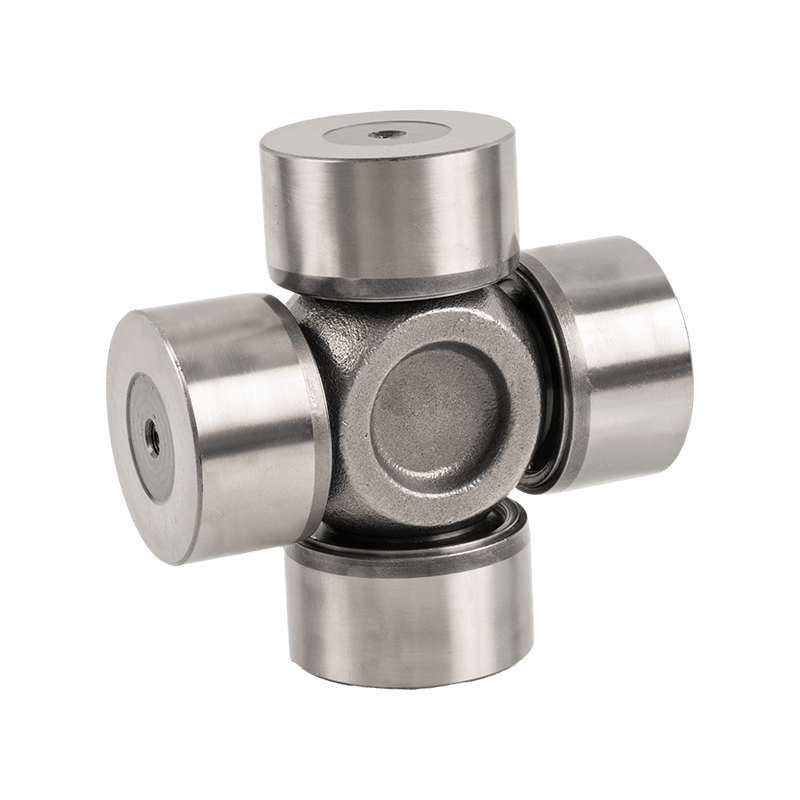

The biggest feature of Russia Cross Joint is its innovative structural design of multi-directional cross connection. This structure realizes multi-angle and multi-directional cross connection of pipeline connection, greatly improving the layout flexibility of pipeline system, especially suitable for applications in complex terrain and changing environment.

Traditional straight pipeline can only be turned through accessories such as elbows, while the design of cross joints allows pipelines in multiple directions to be connected at the same node, reducing the use of accessories and reducing the overall structural complexity. This multi-directional connection form not only simplifies the design scheme, but also greatly improves the construction efficiency. By optimizing the internal mechanical structure, the cross joint can effectively disperse the various stresses generated during pipeline operation and avoid fatigue cracks and breakage caused by stress concentration in traditional joints. Uniform stress distribution not only improves the mechanical strength of the pipeline connection part, but also greatly prolongs the service life.

The joint is compact and reasonable in design, moderate in size, and easy to operate and install on site. The standardized modular design makes on-site installation quick and accurate, greatly reducing labor and time costs, and facilitating future inspection and maintenance. Russia Cross Joint supports the connection of multiple pipe diameters and materials to meet the needs of different pipeline systems. Whether it is a steel pipe, alloy pipe, or composite pipe, the cross joint can achieve reliable connection and meet the complex needs of multiple industries and working conditions.

The operating pressure of oil and gas pipelines is high, especially high-pressure transmission pipelines, which require the joints to withstand extremely high internal and external pressures. Russia Cross Joint uses high-strength alloys with mechanical properties, can withstand hundreds of bars of pressure, and ensure that the connection parts are stable and without deformation. Pipelines are exposed to complex environments for a long time and are often corroded by corrosive media such as seawater, acid and alkali, and salt spray. The use of advanced anti-corrosion alloy materials combined with surface treatment technology effectively improves the corrosion resistance of the cross joint and ensures the long-term safe operation of the pipeline in environments such as oceans, deserts and frozen soil. Oil and gas pipelines span multiple climate zones and have drastic temperature changes. Russia Cross Joint materials have wide temperature adaptability and can withstand high and low temperatures to ensure that the joint materials do not crack or degrade due to temperature differences.

In the process of oil and gas transportation, leakage risk is an important factor affecting safety and environmental protection. Russia Cross Joint adopts a multi-layer sealing design to achieve a tight closure of gas and liquid.

The joint has built-in multi-layer sealing rings and uses elastomer materials, which are both corrosion-resistant and aging-resistant, ensuring long-term stability of the seal and avoiding the risk of leakage. With the help of precision processing technology and intelligent testing equipment, the sealing surface processing accuracy and joint matching degree are guaranteed, ensuring that all components fit tightly without gaps, and the sealing performance reaches the industry-leading level. The sealing design of the Russia Cross Joint can effectively adapt to the dynamic changes caused by the expansion and contraction of the pipeline due to pressure fluctuations and temperature changes, preventing sealing failure.

English

English 中文简体

中文简体