How universal joints improve tractor efficiency in the field: key connection technology behind agricultural equipment

As agricultural mechanization continues to move towards refinement and diversification of scenarios, tractors are gradually transforming from a single power output tool to a multi-functional platform covering all aspects of plowing, planting, management and harvesting. Behind this power machine, the Tractor Universal Joint, as a key component connecting the transmission system and the operating device, is deeply changing the operating efficiency and reliability of the agricultural field through its "multi-condition adaptability". Especially under China's complex agricultural landform conditions, the "flexible transmission, durable structure and adjustable angle" characteristics of the Tractor Universal Joint make it a power bridge connecting hills, mountains, paddy fields and plains.

my country's agricultural operating environment can be described as "a thousand lands and a thousand appearances": the south is undulating with hills and paddy fields everywhere, the north is vast plains and desertified grasslands coexist, and the central and western regions have irregular terrains such as terraces, plateaus, and shrubs. This highly diverse operating environment poses a great challenge to the maneuverability and stability of the tractor. The Tractor Universal Joint is an important "transfer hub" that ensures power continuity and operating stability when the tractor faces a multi-condition environment.

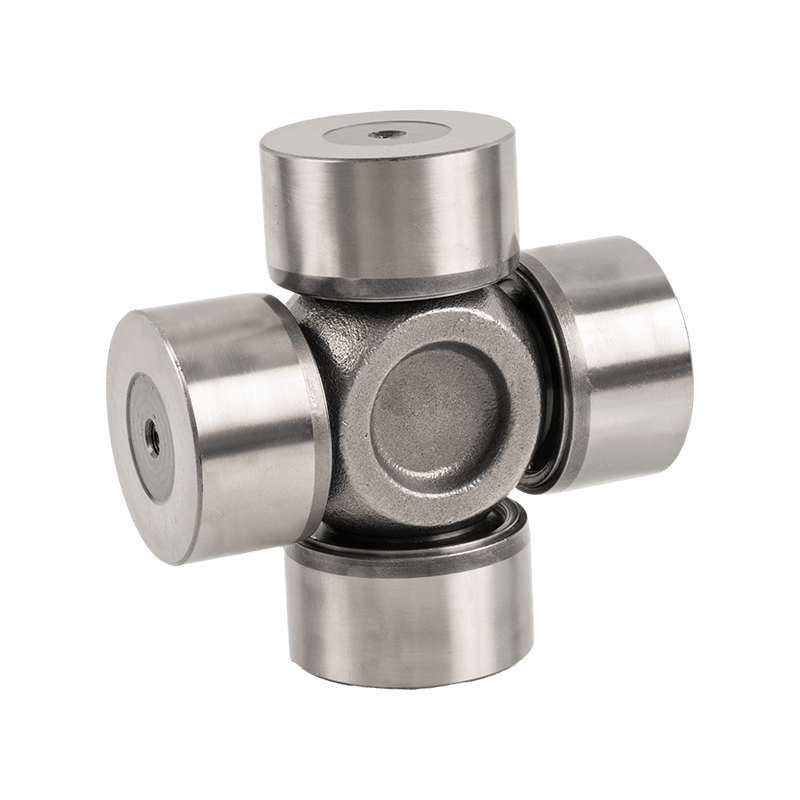

In mountainous and hilly operations, the undulating terrain causes the transmission shaft angle to change frequently. The Tractor Universal Joint maintains stable power output between inclined slopes through its cross-axis flexible structure, avoiding the "stuck" and "broken shaft" problems in traditional rigid connections. In the humid rice-growing areas in the south, the field surface is soft and the terrain is uneven. The paddy field-specific Tractor Universal Joint with a sealing structure and anti-mud design has waterproof, anti-corrosion and anti-mud wear properties, ensuring stable operation in paddy field transplanting, weeding, rotary tillage and other operations. In the northern dryland agricultural areas, sowing and tillage equipment often work continuously for several hours, and the fatigue resistance of the universal joint is extremely high. The high-strength alloy Tractor Universal Joint can withstand high torque output and maintain precise centering during high-speed rotation, greatly reducing the mechanical failure rate.

The agricultural site is not as flat and controllable as the factory workshop, and the ground undulations and resistance changes can be seen everywhere. The biggest technical advantage of the Tractor Universal Joint is that it can still achieve smooth power transmission when there is an angle deviation between the power input and output shafts, thereby ensuring that the tractor and its mounted agricultural implements can work stably on rugged surfaces. A typical scenario is when a tractor pulls a plow for rotary tillage or deep loosening, encounters underground stones or sudden changes in terrain, and the rear of the main engine floats up, causing the angle between the drive shaft and the output end to fluctuate violently. Ordinary rigid connection parts are easily unbalanced or even broken, while the Tractor Universal Joint can automatically adjust the deflection angle to continuously output stable torque to avoid interruption of operation. When the turning radius is small or multiple operating equipment are mounted, the Tractor Universal Joint can achieve multi-axis coordinated rotation, buffer vibration, and improve steering flexibility and overall machine controllability.

Benefiting from the refined development of agricultural scenarios and the acceleration of machinery renewal, the demand for Tractor Universal Joint continues to grow in the domestic market. Whether it is medium and large agricultural enterprises, rural cooperatives, or individual farmers, when purchasing tractors or updating parts, they pay more and more attention to the standards of "durable, flexible, and anti-interference" of universal joints. At the same time, orders from developing agricultural markets such as Southeast Asia, Africa, and Latin America are also growing rapidly. Due to the complex terrain and urgent need for increased mechanization, the Tractor Universal Joint made in China has become a popular export product with its "high cost-effectiveness + strong adaptability" characteristics.

English

English 中文简体

中文简体