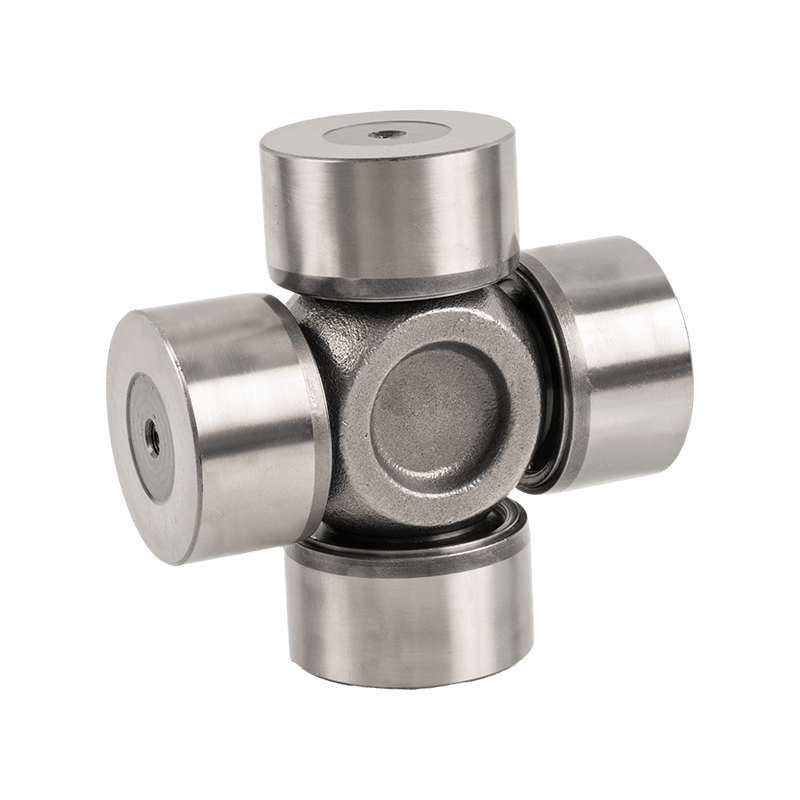

Energy saving and environmental protection, Toyo Universal Joint's contribution to improving mechanical efficiency

With the increasing demand for energy saving and efficiency in industrial equipment, how to improve the overall performance of the mechanical system and reduce unnecessary energy waste has become an important issue in modern manufacturing. As a core component in the transmission system, Toyo Universal Joint has greatly improved the overall efficiency of the equipment through its design and technical advantages, while helping companies reduce operating costs.

The efficient transmission characteristics of Toyo Universal Joint enable mechanical equipment to complete more work in a shorter time, optimize the efficiency of energy use, and ultimately significantly improve the overall operating efficiency of the equipment. With the improvement of equipment efficiency, operating costs are naturally greatly reduced, especially in heavy machinery and industrial equipment that require continuous and stable operation. This advantage is particularly prominent. Toyo universal joints ensure that the equipment can maximize the use of input energy during operation by reducing energy loss and improving transmission efficiency. While improving efficiency, Toyo universal joints help reduce the energy consumption of mechanical systems. For many mechanical equipment that need to run for a long time, improving energy efficiency directly reduces the consumption of resources such as electricity and fuel. Improving equipment operating efficiency means that unnecessary maintenance and repair costs can be reduced. Due to the structural optimization and material selection of Toyo universal joints, its service life is longer than that of traditional universal joints, which reduces equipment downtime and avoids expensive repair costs caused by improper maintenance or damage.

The high durability and high-quality materials of Toyo universal joints enable them to work stably under harsh conditions such as high loads and high temperatures, greatly extending the service life of mechanical equipment. Fewer failures and wear not only reduce the frequency of repairs and replacement of parts, but also significantly reduce related maintenance costs. The efficient and low-wear Toyo universal joints reduce the costs caused by frequent replacement of parts. In contrast, traditional universal joints require more frequent replacement due to wear problems, while Toyo universal joints reduce these additional maintenance expenses through their durability. Due to the efficient performance and durability of Toyo universal joints, equipment downtime is significantly reduced. The equipment can maintain efficient operation for a longer period of time, which not only improves production efficiency but also reduces indirect operating costs caused by downtime.

The precision design of Toyo universal joints makes it more stable during work, greatly reducing the possibility of system failure. When the equipment is running, the stability of the system is one of the key factors in reducing operating costs. By reducing the frequency of equipment failures, Toyo universal joints ensure the continuity of the production process and avoid additional repair costs caused by failures. Toyo universal joints have extremely high reliability and can work stably even under high loads. The high temperature resistance, corrosion resistance and wear resistance of Toyo universal joints enable them to adapt to various complex working conditions and maintain long-term stable operation.

The efficiency of Toyo universal joints directly affects the energy consumption of the entire equipment, especially in large-scale mechanical equipment that needs to run continuously for a long time. By reducing energy losses, Toyo universal joints help companies optimize the use of resources and further improve production efficiency. Due to its efficient transmission characteristics, Toyo universal joints can reduce energy losses and unnecessary energy consumption. This can effectively reduce energy expenses and operating costs for industrial production that requires a lot of energy input. By improving the efficiency of the overall mechanical system, Toyo universal joints can make better use of limited energy resources. This not only helps companies reduce operating costs, but also reduces the burden on the environment.

English

English 中文简体

中文简体