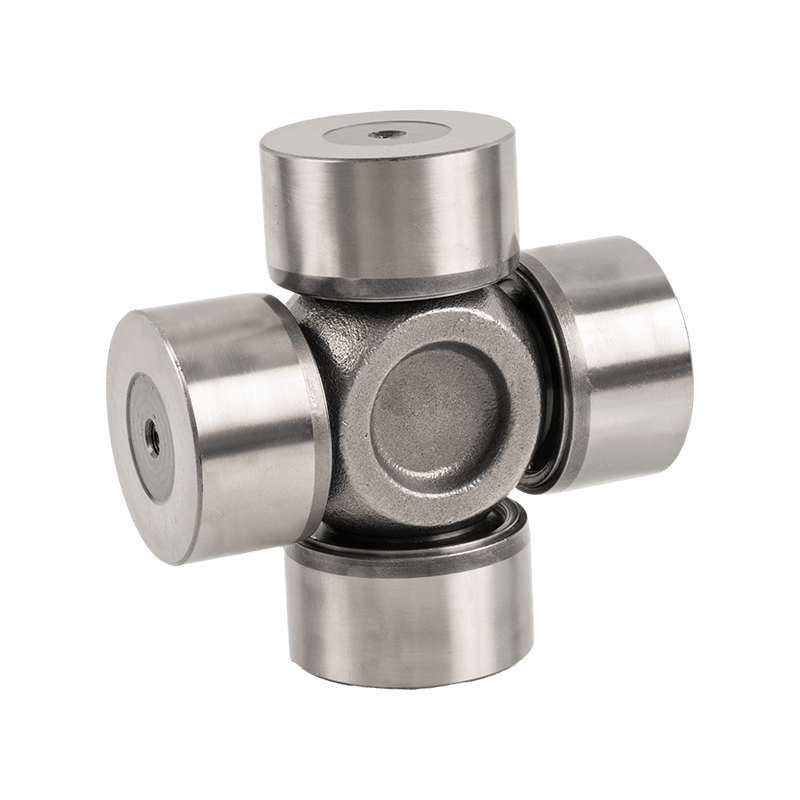

High-quality 2-groove bearing and plain bearing universal joints that meet stringent industrial standards

With the increasing demand for efficient and durable mechanical parts in the manufacturing industry, 2-groove bearing and 2-plain bearing universal joints have become important components widely used in many industries. This universal joint product uses top-quality materials and precision craftsmanship, and is designed for industrial applications with high loads and high durability requirements to ensure excellent performance in harsh operating environments.

The crosshead and cup of this universal joint are made of high-performance alloy steel, including 20Chromium, 20CrMnTi, 8620, SCM415 and other alloy materials. These alloy steels undergo a special heat treatment process during the manufacturing process, which optimizes the internal structure of the material and further improves its hardness, compressive strength and fatigue resistance. This treatment method not only enhances the mechanical properties of the material, but also ensures the stability and safety of the universal joint, and adapts to more complex working conditions.

The product complies with multiple international standards, including DIN, ANSI/ASME, BS, GB, JIS, etc., and has passed IATF 16949 certification, which is one of the standards for quality management in the global automotive industry, requiring manufacturers to have continuously improved production processes, strict quality control and efficient risk management. With this certification, the manufacturing process of the product can guarantee a strict quality control system, reducing potential defects and quality fluctuations in the production process.

This universal joint is widely used in many fields such as automobiles, heavy machinery, and industrial equipment, especially in refrigeration, air-conditioning systems, heavy trucks, mobile equipment and industrial machinery. With its diverse specifications and models, it can perfectly adapt to different equipment and work needs,

The design of the universal joint not only focuses on performance, but also takes into account the user's use needs. Through precision machining, with straight threads of different specifications and standard interfaces, it ensures that each joint can be installed and removed quickly and stably. In terms of packaging, natural packaging, color packaging and wooden pallet packaging are provided to meet the transportation and storage needs of different customers.

The production line of this product supports multiple delivery methods such as FOB, CIF, CNF, EXW, etc., ensuring that customers can obtain products in a timely manner according to their needs. The monthly supply capacity can reach 600,000 to 800,000 sets to ensure that the needs of bulk orders can be met.

English

English 中文简体

中文简体