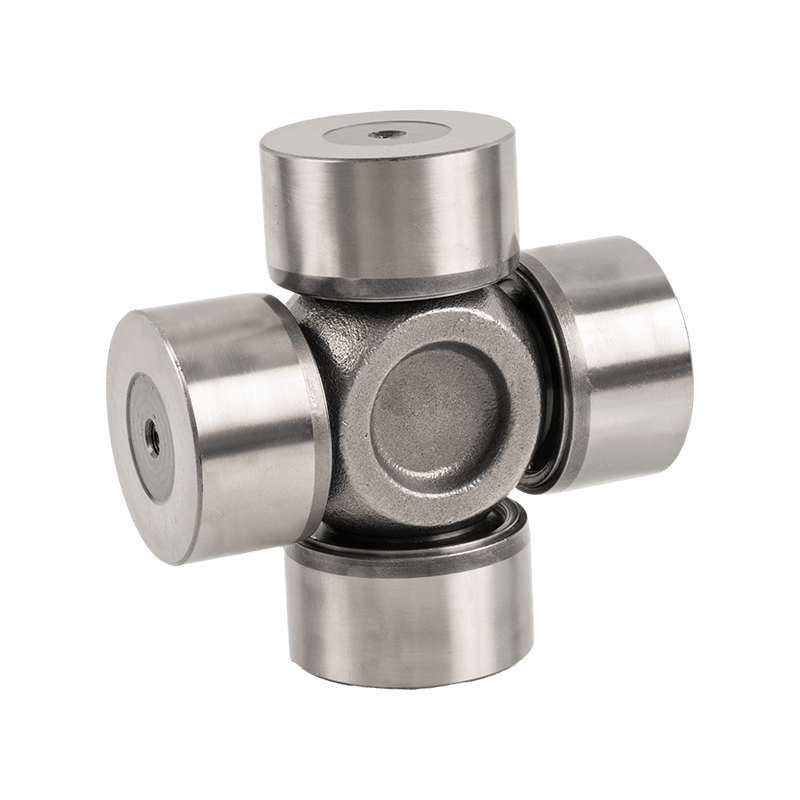

Four-wing bearing wing-shaped universal joint, providing larger angle and higher transmission efficiency

The four-wing bearing wing-shaped universal joint adopts an innovative wing-shaped gear design, which allows it to automatically compensate for angle changes when transmitting high torque. This adaptive feature enables the wing-shaped universal joint to always maintain efficient torque transmission during operation, ensuring that power is not lost regardless of how the angle changes, thereby improving the stability and performance of the overall system.

In traditional universal joints, axis deviation will lead to reduced transmission efficiency and even cause equipment failure. The four-wing bearing wing-shaped universal joint adopts a wing-shaped gear structure, which can maintain stable rotation in the case of large angle deviation, without jamming or reduced transmission efficiency. Its tooth design can automatically adjust the angular displacement when the axis has a certain deviation, thereby maintaining efficient torque transmission. This allows it to provide higher flexibility in complex industrial environments and is widely used in equipment that requires high angle adjustment and large torque transmission.

The structural design of the wing-shaped universal joint allows it to maintain a stable transmission state under large angle deviations, ensuring higher transmission efficiency. Traditional universal joints are easily affected by friction under high loads, resulting in wear and reduced efficiency. The wing gear design of the wing universal joint not only enhances the contact force between the contact surfaces, but also reduces friction by optimizing the tooth design, thereby extending the service life and reducing maintenance costs. The wing universal joint uses strong materials and precise manufacturing processes to withstand higher torque loads than traditional universal joints. This allows it to work stably under extreme loads and adapt to heavy machinery applications that need to transmit a large amount of torque. Whether in automobiles, agricultural machinery, or mining and heavy industrial equipment, the four-wing bearing wing universal joint can provide continuous and stable torque transmission to ensure the smooth operation and long service life of the equipment. High torque transmission often causes system vibration and noise, especially in traditional universal joints, where the vibration problem is more obvious due to axis misalignment or low transmission efficiency. The structure of the wing universal joint can effectively reduce these problems, provide smoother and quieter operation, and avoid the additional vibration and noise caused by unbalanced transmission in the system.

Because the wing universal joint can efficiently transmit large torque and maintain stability under large angle deviations, its use greatly improves the reliability of the overall transmission system. Even in harsh working environments, the operation of the equipment can remain stable, reducing the failure rate and maintenance costs. This four-wing bearing wing-shaped universal joint is not only suitable for ordinary mechanical transmission devices, but also can perform excellently in some fields requiring high loads and large angle changes. It is widely used in automobile transmission systems, agricultural machinery, construction machinery and other heavy machinery, solving the problem of shaft docking under various complex working conditions and improving the reliability and work efficiency of the overall system.

English

English 中文简体

中文简体