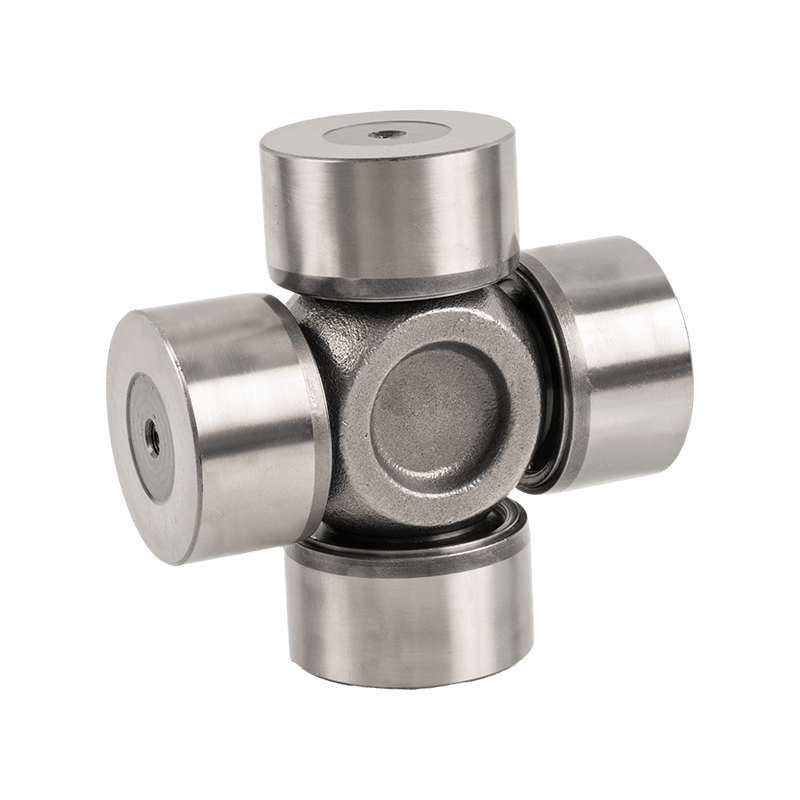

Industrial equipment cross kit: made of high-quality alloy steel to meet global standards

The main components of the cross kit, including the cross and cup, are made of a variety of high-strength alloy steel materials such as 20Chromium, 20CrMnTi, 20CrMo, 8622H, 8620, etc. These materials have excellent wear resistance, corrosion resistance and strength, ensuring the long-term stable operation of the kit under high-load environments. High-strength alloy steel materials such as 20CrMnTi, 8622H and 8620 are outstanding in hardness and wear resistance, and can effectively resist friction and wear. This means that the cross kit can maintain long-term stable performance even under high-load and high-impact conditions, extending its service life. Alloy steel materials such as 20Chromium and 20CrMo have strong corrosion resistance and can resist erosion by moisture, chemicals and other harsh environmental factors. This allows the cross kit to maintain its structural integrity and functionality in a variety of harsh environments, especially suitable for industries such as automotive, construction and heavy machinery. These alloy steel materials have a good combination of strength and toughness, and can withstand large impacts and pressures without breaking or deforming easily. In particular, materials such as 20CrMnTi, after quenching and tempering, have high hardness and fatigue resistance, and can maintain stable performance in high-intensity operations. These alloy steel materials enable cross kits to withstand greater loads and pressures, especially in industrial applications that require high load-bearing capacity, such as heavy machinery, vehicle transmission systems, etc. They can effectively improve the load-bearing capacity of the product and avoid damage or excessive wear under high load conditions.

At the same time, the universal joint kit uses 65Mn and ZQ235 materials. 65Mn steel is a high-strength spring steel with good toughness and wear resistance. After heat treatment, it can provide very high tensile strength and fatigue resistance, which enables the universal joint to maintain stable performance and reduce the risk of breakage or wear when subjected to high-intensity mechanical shock and dynamic loads, and has excellent fatigue resistance. Under repeated pressure and stress, it can maintain stable performance for a long time and avoid fatigue cracks or fractures, which makes the universal joint more durable in frequent load changes and long-term use. ZQ235 is a low-carbon structural steel with good plasticity and welding properties. It can withstand high pressure and shock and is suitable for a variety of high-load industrial applications. ZQ235 has moderate corrosion resistance, especially in environments with temperature changes and high humidity, which can effectively prevent oxidation and corrosion. This helps to improve the performance of the universal joint in harsh environments and enable it to maintain stable performance for a longer time. For mechanical equipment that needs to be used for a long time in harsh environments, the corrosion resistance ensures that the universal joint will not lose its function due to material degradation.

This cross kit complies with multiple international standards such as DIN, ANSI/ASME, BS, GB, JIS, etc., and is certified by IATF 16949 to ensure that the product quality meets global industry requirements. Whether it is used in heavy machinery, the automotive industry, or other applications that require high durability, the LB brand cross kit can provide an ideal solution.

The cross kit provides a bright black coating and phosphating treatment, which not only enhances the appearance, but also enhances the corrosion resistance and adapts to various complex environments. Through a special surface treatment process, the LB brand cross kit can resist wear, oxidation and environmental influences, extending the service life of the product.

In order to better meet the diverse needs of customers, flexible customization options are provided. Whether in color, packaging, or brand logo, it can be customized according to customer requirements to meet the needs of different markets. In addition, different payment terms and delivery methods are provided, including T/T, LC payment, and FOB/CIF/CNF/EXW and other delivery terms, which are convenient for global customers to purchase.

English

English 中文简体

中文简体