How Agricultural Machinery U-Joints Enhance Efficiency in Modern Farming

Content

In modern farming, the efficiency of agricultural machinery plays a critical role in optimizing productivity and reducing operational costs. As farms continue to grow in scale and technology advances, the machinery used must operate seamlessly to handle diverse and often demanding tasks. One small yet essential component that contributes significantly to this efficiency is the U-joint (Universal Joint). Though often overlooked, the U-joint plays a pivotal role in transmitting power between different parts of agricultural equipment, ensuring smooth operations, reduced downtime, and overall better performance.

1. Understanding U-Joints and Their Role in Agricultural Machinery

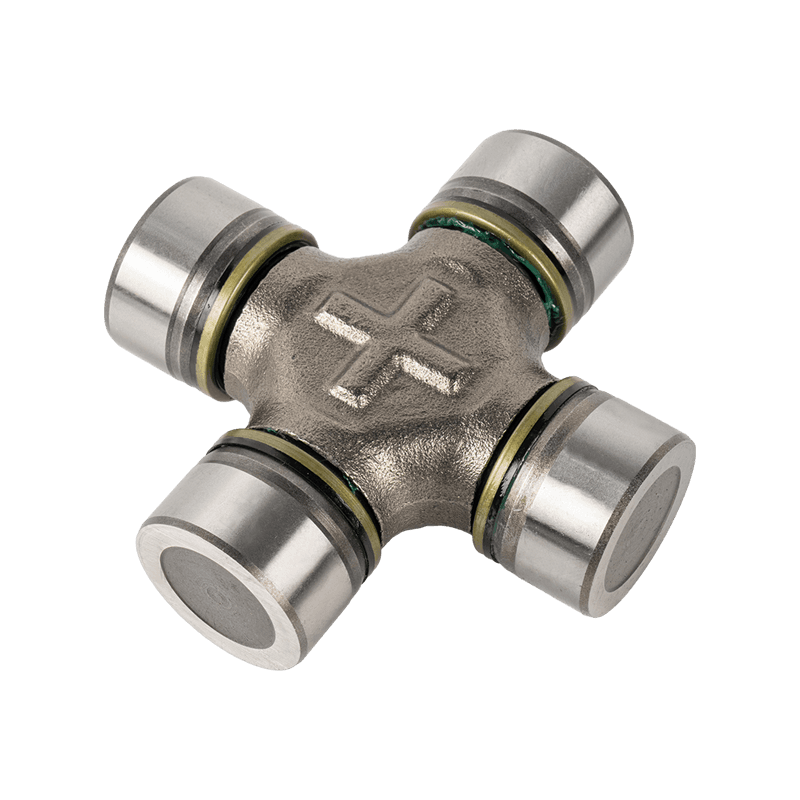

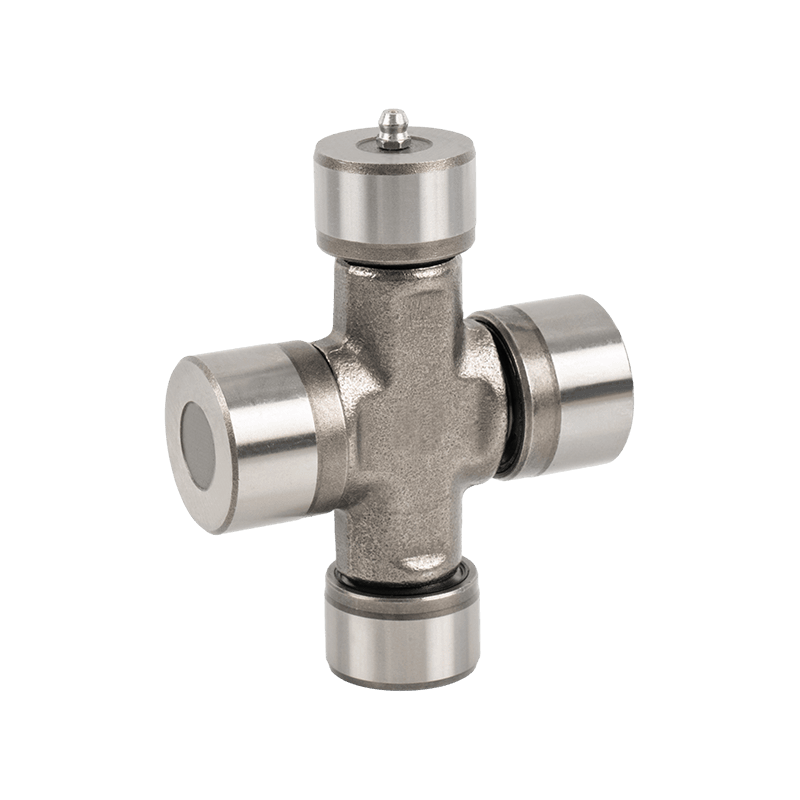

A U-joint, also known as a universal joint, is a mechanical component used to transmit rotary motion and torque between two shafts that are not in line with each other. In agricultural machinery, U-joints are primarily used in drive shafts to connect various components of the machine, such as the engine, gearbox, and wheels, allowing for the transfer of power without any disruption.

U-joints are crucial in maintaining the machine’s ability to operate smoothly across a variety of terrains and in various conditions. Whether it’s a combine harvester, tractor, or a plowing machine, the U-joint ensures that the machinery can handle the constant movement and stress that comes with agricultural work. They are typically designed to handle high torque and rotational forces, often operating in extreme conditions like wet soil, mud, and dust.

2. Key Advantages of U-Joints in Agricultural Equipment

a) Smooth Power Transfer

One of the most significant advantages of U-joints in agricultural machinery is their ability to ensure smooth power transfer between components. Power needs to flow continuously and evenly from the engine to the wheels or implements (like plows, harvesters, or tillers). Without the U-joint, machinery would suffer from jerky or uneven power transmission, leading to performance inefficiencies and potential breakdowns.

U-joints enable shafts to maintain rotational motion at varying angles, compensating for changes in the machinery’s position. This results in smooth and consistent operation, even when the angle between connected parts changes due to terrain or machinery adjustments.

b) Increased Durability and Performance

Agricultural machinery operates under harsh conditions. Whether in muddy fields, during extreme weather, or on rocky terrain, the stress on components is immense. U-joints are designed to withstand these high stress loads, ensuring that power is effectively transmitted without interruptions.

By maintaining a constant torque and rotational flow, U-joints contribute directly to the longevity of the equipment. The continuous operation of agricultural machinery places significant pressure on all moving parts, but a well-maintained U-joint helps absorb some of this stress, reducing wear and tear on the rest of the machinery and contributing to overall durability.

c) Flexibility in Equipment Usage

Farmers rely on various types of equipment to perform different tasks, such as plowing, planting, and harvesting. U-joints play an important role in ensuring the flexibility of these tasks. With their ability to adjust angles, U-joints allow farm machinery to operate in multiple configurations, whether it's the angle of a harvester’s blade or the direction of a tractor’s attachments.

For instance, when using a tractor with a plow, the U-joint ensures that the torque from the engine can be transferred to the plow at an angle, even if the terrain or the attachment angle changes. This flexibility improves the ability to use the same equipment for different tasks without requiring significant adjustments or the need for multiple machines.

d) Reducing Maintenance Costs

Maintaining agricultural machinery can be costly and time-consuming. U-joints, when properly maintained, contribute significantly to reducing overall maintenance costs. Because U-joints are built to absorb shock and manage high forces, they help prevent the more expensive damage that can occur when power is transferred inefficiently. This can prevent breakdowns that might otherwise require costly repairs or replacements of larger components like the transmission or engine.

Moreover, high-quality U-joints are designed for longevity. With proper lubrication and periodic checks, they can last for a long time, reducing the need for frequent replacements. This makes them a cost-effective component in the long run.

3. U-Joints in Common Agricultural Machinery

Several types of agricultural machinery rely heavily on U-joints to function efficiently. Let’s take a look at some of the most common machinery where U-joints are indispensable:

a) Tractors

Tractors are at the heart of modern farming, performing a wide range of tasks, from tilling soil to towing equipment. U-joints are an integral part of the tractor’s drive shaft, allowing power to be transmitted to the wheels and attached implements. They also help maintain consistent power flow when the tractor is navigating uneven terrain, ensuring that it operates smoothly.

b) Combine Harvesters

In combine harvesters, U-joints are used to connect the power from the engine to the various moving parts, such as the grain header and the threshing drum. These machines work in extremely demanding conditions, harvesting large quantities of crops. U-joints help maintain consistent rotational speed and power, ensuring that the harvester operates efficiently throughout the harvesting process.

c) Plows and Tillers

Plows and tillers are key tools for soil preparation. They are often towed behind tractors and rely on U-joints to ensure that power is properly transferred from the tractor’s engine to the plowing mechanism. This enables the tiller or plow to break up soil efficiently, even in challenging terrain or when dealing with hard or compacted soil.

d) Balers

Balers are used to compress hay, straw, or other crops into compact bales. These machines rely on U-joints to transmit power to their complex mechanical systems. The U-joint allows for the necessary motion of the bale-pressing mechanism while maintaining consistent torque, ensuring high-performance operation and minimizing breakdowns.

4. Maintaining U-Joints for Maximum Efficiency

While U-joints are designed to be durable, proper maintenance is key to ensuring that they continue to enhance the efficiency of agricultural machinery. Here are some essential tips for maintaining U-joints:

a) Regular Lubrication

Regular lubrication helps to reduce friction and wear, ensuring that the U-joint operates smoothly. Most U-joints require periodic greasing to prevent dirt and moisture from damaging the bearings.

b) Inspecting for Wear and Tear

Over time, U-joints can experience wear, particularly in high-stress applications. Routine inspections to check for any signs of cracking, rust, or looseness are essential to catch potential issues before they lead to mechanical failure.

c) Replacing Worn U-Joints

If a U-joint becomes damaged or worn out, it’s crucial to replace it promptly. Operating with a damaged U-joint can result in misalignment, poor performance, or even catastrophic failure of the machinery.

English

English 中文简体

中文简体