How the 4-Staked Plain Round Steering Joint Contributes to the Longevity of Steering Systems

Content

When it comes to a vehicle’s steering system, longevity and reliability are paramount. As one of the most crucial parts of automotive engineering, the steering joint ensures that the driver can precisely control the vehicle’s direction. However, this component faces significant wear and tear over time due to constant motion, friction, and exposure to environmental elements.

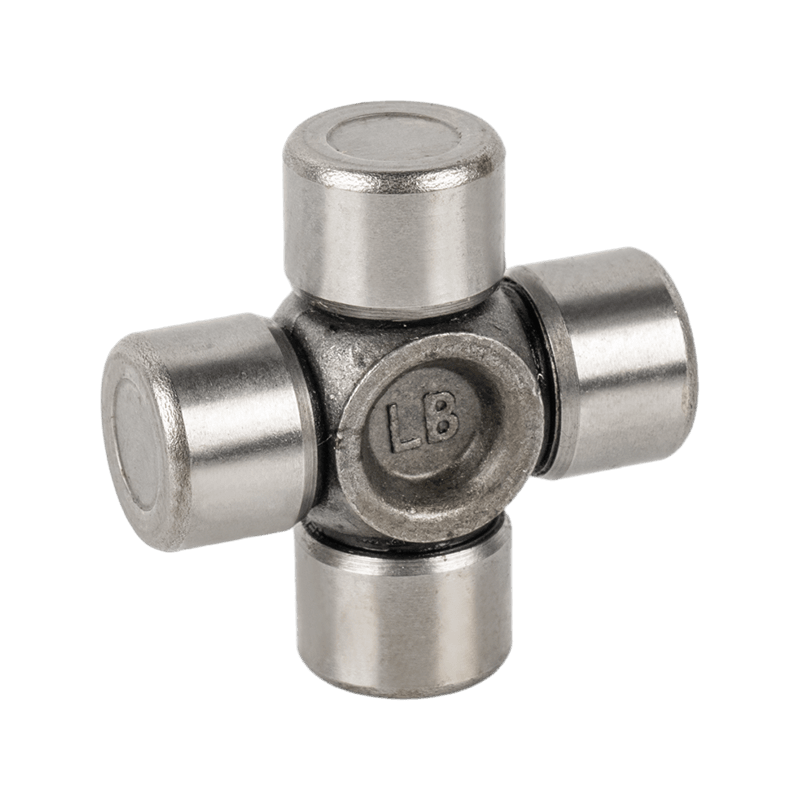

A steering joint that wears out prematurely can cause steering instability, difficulty in control, and, at worst, complete failure. This leads to costly repairs, downtime, and potential safety risks. The WITH 4 STAKED PLAIN ROUND STEERING JOINT has emerged as a revolutionary design to enhance the lifespan and efficiency of steering systems.

Why the 4-Staked Plain Round Steering Joint is Key to Steering System Longevity

The 4-staked plain round steering joint stands out because of its design, which provides superior durability, reduced friction, and improved structural integrity. These attributes make it an essential component for any vehicle aiming for a long-lasting and reliable steering system. Let’s break down the main reasons why this joint plays such a critical role in extending the longevity of the steering system:

Reinforced Structure for Enhanced Durability

One of the defining features of the 4-staked plain round steering joint is its reinforced structure, which incorporates four stakes that securely lock the joint into place. Unlike traditional steering joints that rely on simple press-fit or pinning designs, the 4-staked joint offers added stability, ensuring that the joint stays firmly attached even under extreme stress and movement.

This robust structure makes the joint less prone to becoming loose or misaligned, two common issues that can lead to premature steering system failure. By providing greater strength and stability, the 4-staked design ensures that the steering system remains fully functional over time, reducing the likelihood of early wear and avoiding costly repairs.

This added durability is particularly crucial for vehicles that experience high levels of stress or frequent use, such as commercial trucks, off-road vehicles, and high-performance sports cars.

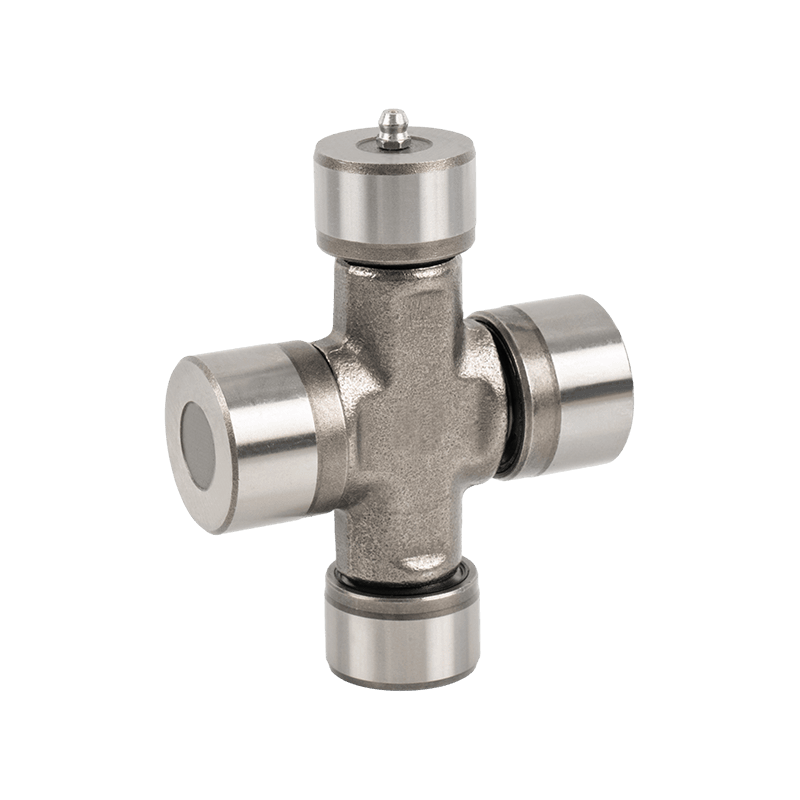

Reduced Friction and Smoother Operation

Friction is one of the leading causes of wear in steering components. When steering joints rub against other parts of the system, it generates heat, increases wear, and can lead to misalignment or poor performance. The 4-staked plain round steering joint has been specifically engineered to reduce friction.

The smooth, round design ensures that the joint moves freely within its housing, offering less resistance during operation. This friction reduction has several benefits:

-

Lower heat generation: Less friction means less heat buildup, which can degrade surrounding components.

-

Reduced wear: With smoother operation, there’s less strain on the joint and its surrounding components, ensuring they last longer.

-

Improved performance: A smoother steering experience provides more precise control and a quicker response, enhancing driving comfort and safety.

By minimizing friction, the 4-staked plain round steering joint not only helps keep the steering system running smoothly but also ensures that it continues to do so for longer periods without requiring maintenance or repair.

Resistance to Environmental Damage

Steering joints are exposed to harsh environmental conditions, such as rain, snow, road salt, and mud. Over time, these elements can cause significant damage to traditional joints, resulting in corrosion, rust, and degradation of the materials. This leads to a shortened lifespan for the steering system.

The 4-staked plain round steering joint is designed with superior resistance to environmental factors. The corrosion-resistant materials used in its construction, coupled with the tight fit of the stakes, make it more impervious to water, dirt, and salt. This resistance ensures that the joint remains intact, even in the most challenging climates, without succumbing to corrosion or degradation.

Additionally, the round design of the joint helps create a better seal, preventing contaminants from getting inside the joint and causing internal damage. For vehicles that are exposed to harsh road conditions, such as off-road trucks or winter vehicles, this feature significantly enhances the longevity of the steering system.

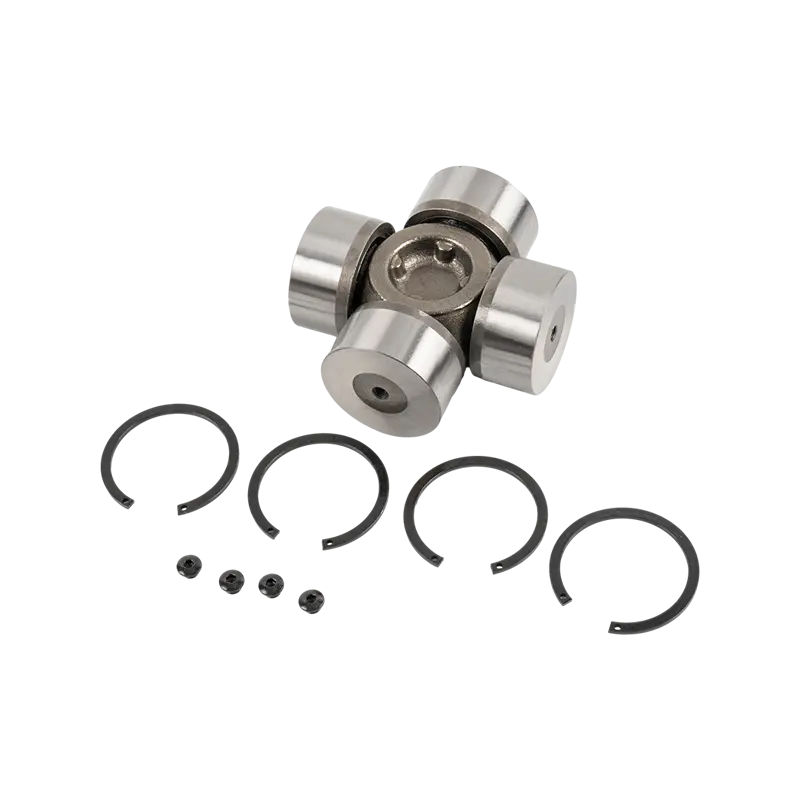

Improved Alignment and Reduced Maintenance

Misalignment in steering joints is a common issue that can lead to uneven wear and premature failure of the steering components. When joints are misaligned, it can cause the entire steering system to work inefficiently, putting additional strain on the system. However, the 4-staked plain round steering joint excels in maintaining proper alignment.

The four stakes create a secure connection that minimizes the chances of shifting or misalignment. This ensures that the joint maintains a precise fit over time, preventing any unnecessary wear or damage to other components. As a result, the joint operates smoothly, and the steering system experiences less stress and strain.

With better alignment comes less frequent maintenance. Unlike traditional joints that may need regular inspections, lubrication, or adjustments, the 4-staked plain round steering joint stays in place and continues to function optimally for longer periods. This means that vehicle owners and fleet managers can expect lower maintenance costs and fewer service visits.

The Long-Term Impact: Fewer Repairs and Enhanced Performance

The 4-staked plain round steering joint does more than just extend the lifespan of a vehicle’s steering system—it also improves overall performance. By enhancing durability, reducing friction, and providing better environmental resistance, this joint ensures that the vehicle’s steering system remains responsive and precise over the long term.

Drivers will notice smoother steering and more precise control, particularly in vehicles that are subjected to rigorous driving conditions, like towing, off-roading, or high-speed driving. For fleet operators, this means fewer instances of steering instability and costly downtime—resulting in a more reliable and durable fleet.

English

English 中文简体

中文简体