Why the 4 Wings Bearing U-Joint Is a Must-Have for Commercial Vehicle Fleet Maintenance

Content

In the ever-evolving world of fleet maintenance, keeping commercial vehicles running smoothly is a complex, yet critical, task. Fleet managers and mechanics are continually looking for ways to improve the durability and efficiency of vehicles, reduce downtime, and ultimately minimize operating costs. One often overlooked but essential component in this equation is the U-joint—specifically, the 4 Wings Bearing U-Joint. While traditional U-joints have been standard in powertrain applications for decades, the 4 Wings Bearing U-Joint offers distinct advantages that make it an invaluable asset for commercial vehicle fleet maintenance.

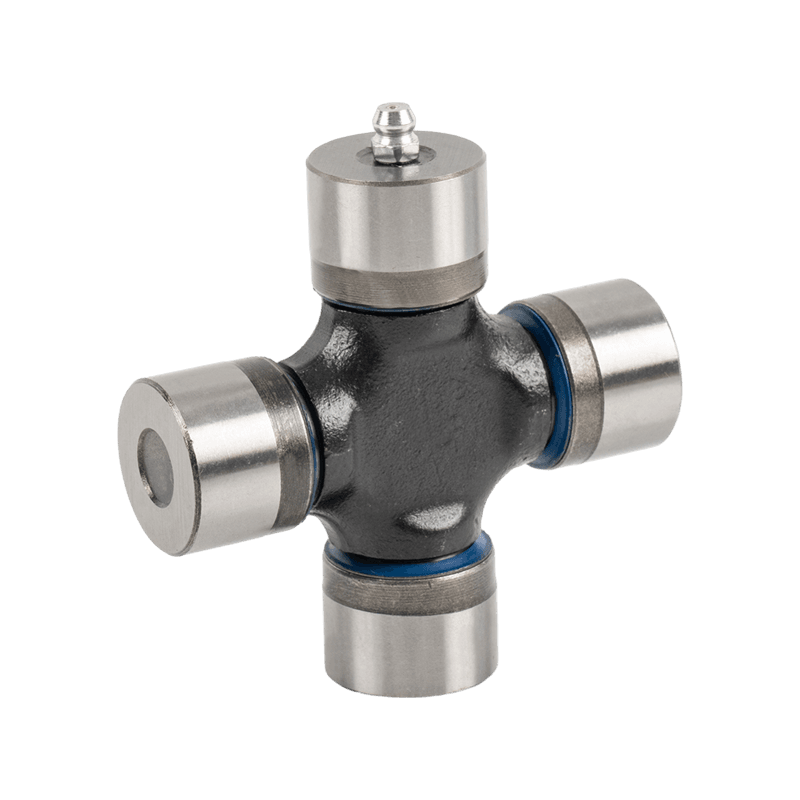

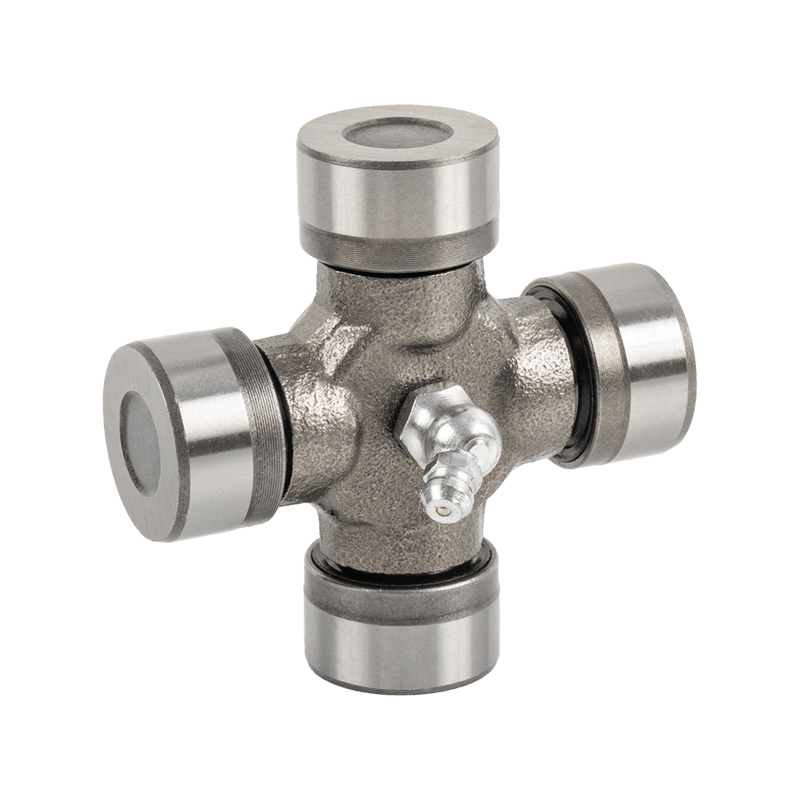

What Is a 4 Wings Bearing U-Joint?

The 4 Wings Bearing U-Joint is a specialized type of universal joint (U-joint) that is used to transmit rotary motion and torque between two shafts at varying angles. It is commonly found in drive shafts of vehicles, including trucks, buses, and other heavy-duty commercial vehicles. The "4 wings" refers to the unique design of the bearing caps, which are equipped with four arms that provide enhanced strength, support, and stability compared to traditional U-joints. This configuration allows for greater flexibility and durability, especially in high-stress applications.

Unlike traditional U-joints with a single bearing, the 4 Wings Bearing U-Joint uses four distinct bearing contact points to distribute the load more evenly, reducing wear and improving the lifespan of the joint. This makes it ideal for the heavy-duty demands placed on commercial vehicle drivetrains, especially for long-haul trucking or construction vehicles.

The Importance of U-Joints in Commercial Vehicle Fleets

In a commercial fleet, every component of the vehicle is designed to withstand constant use under harsh conditions. The U-joint plays a vital role in transmitting power from the engine to the wheels, enabling the vehicle to move. However, since U-joints are exposed to intense stress, vibration, and harsh environmental factors such as dust, moisture, and road debris, they are particularly prone to wear and tear.

A failing U-joint can lead to severe mechanical issues, including:

Loss of Power: If the U-joint fails, the vehicle may lose the ability to transfer power from the engine to the wheels, rendering it inoperable.

Increased Vibration: Worn U-joints cause excessive vibration, which can result in a rough ride, reduced driving comfort, and, in extreme cases, damage to the entire drivetrain.

Increased Downtime: Fleet vehicles that experience U-joint failure may require extensive repairs or even replacement, resulting in costly downtime and delays.

For fleet managers, ensuring that U-joints are in good working condition is critical to maintaining operational efficiency, minimizing unscheduled downtime, and avoiding costly repairs. This is where the 4 Wings Bearing U-Joint comes into play.

Key Benefits of the 4 Wings Bearing U-Joint for Commercial Fleets

Enhanced Durability and Longevity

The most significant advantage of the 4 Wings Bearing U-Joint is its superior durability. Traditional U-joints often suffer from premature wear due to uneven load distribution, especially under high torque conditions. The four-wing design of this U-joint helps distribute loads more evenly across the bearing surface, reducing wear and tear on the components. This leads to a significantly longer service life, which is a huge benefit for commercial vehicle fleets that need to maximize vehicle uptime and minimize maintenance costs.

By choosing a 4 Wings Bearing U-Joint, fleet managers can extend the time between replacements, reducing the overall lifecycle cost of each vehicle in the fleet.

Reduced Vibration and Noise

Excessive vibration and noise are common problems caused by worn or improperly functioning U-joints. In commercial vehicles, especially those involved in long-haul trucking, constant vibration can not only create an uncomfortable driving experience but also cause damage to other critical components in the drivetrain. The 4 Wings Bearing U-Joint, thanks to its reinforced design and precise load distribution, helps minimize vibration, ensuring a smoother ride.

Reduced vibration also means that other parts of the vehicle, such as the transmission, differential, and drive shaft, experience less stress, ultimately extending their lifespan and improving overall vehicle performance.

Better Handling and Power Transmission

The 4 Wings Bearing U-Joint's ability to provide more even torque distribution ensures that power is transmitted more efficiently across the drivetrain. In commercial vehicles, especially large trucks and delivery vans that require heavy-duty torque, efficient power transmission is crucial. A well-functioning U-joint ensures that the wheels receive the necessary power to drive the vehicle, even under heavy loads or at varying angles.

For fleets operating in industries such as construction, mining, or long-distance freight, reliable power transmission is essential for getting the job done. With the 4 Wings Bearing U-Joint, fleet managers can trust that their vehicles will maintain optimal performance even in tough conditions.

Improved Resistance to Environmental Stressors

Commercial vehicles are often subjected to harsh environmental conditions. Whether it's high heat, extreme cold, or exposure to dust, dirt, and moisture, the conditions can accelerate wear on standard U-joints. The 4 Wings Bearing U-Joint, designed with higher-quality materials and better sealing, is more resistant to these environmental stressors. Its superior protection against moisture, dirt, and corrosion makes it a better choice for fleets operating in challenging environments, such as construction sites or regions with extreme weather conditions.

This added protection ensures that the U-joints remain functional and durable for a longer period, which helps reduce maintenance efforts and costs for fleet owners.

Reduced Maintenance and Downtime

One of the most attractive benefits of the 4 Wings Bearing U-Joint for commercial fleets is the reduction in maintenance and downtime. Traditional U-joints can require frequent inspection, lubrication, and eventually replacement, which can be time-consuming and costly. With its increased lifespan and durability, the 4 Wings Bearing U-Joint reduces the frequency of these interventions.

Fleets with a large number of vehicles need to keep their vehicles running as efficiently as possible. The longer the lifespan of critical components like U-joints, the less time mechanics need to spend on repairs, and the more vehicles can stay on the road generating revenue. Fleet owners can save on labor costs, parts replacement, and, most importantly, reduce the loss of income due to vehicle downtime.

Enhanced Safety

The health of a fleet's drivetrain directly impacts the safety of its drivers. A failing U-joint can lead to catastrophic failure, potentially causing a vehicle to become uncontrollable, resulting in accidents or even severe injury. By opting for a 4 Wings Bearing U-Joint, fleet managers can ensure that the power transmission system is robust, reliable, and safe. This reduces the likelihood of breakdowns on the road, particularly in high-traffic or dangerous areas, enhancing the overall safety of drivers and other road users.

Cost-Effectiveness

While the initial cost of a 4 Wings Bearing U-Joint may be higher than that of a traditional U-joint, the long-term savings far outweigh the upfront expense. With longer service life, reduced maintenance costs, fewer replacements, and minimized downtime, fleet operators will see a substantial return on investment (ROI). In the world of fleet maintenance, where cost control is essential, investing in quality components like the 4 Wings Bearing U-Joint can lead to significant savings in the long run.

Applications of the 4 Wings Bearing U-Joint in Commercial Fleets

The versatility of the 4 Wings Bearing U-Joint makes it applicable in a wide range of commercial vehicle applications:

Heavy Trucks and Freight Vehicles: Long-haul trucks carrying heavy loads benefit significantly from the durability and efficiency of the 4 Wings Bearing U-Joint.

Construction Equipment: Bulldozers, backhoes, and excavators depend on heavy torque, making the 4 Wings Bearing U-Joint ideal for these applications.

Buses and Passenger Vehicles: Public transportation fleets also rely on these high-performance U-joints for reliable power transmission.

Off-Road Vehicles: Vehicles used in off-road conditions, like mining trucks or forestry vehicles, see a marked improvement in performance and durability when equipped with 4 Wings Bearing U-Joints.

English

English 中文简体

中文简体