Why the 4 Welded Plate Type U-Joint is the Backbone of Heavy-Duty Applications

Content

In the world of industrial machinery, automotive systems, and heavy-duty equipment, reliable power transmission is a critical factor in ensuring optimal performance and longevity. One component that has proven itself indispensable in these environments is the 4 welded plate type U-joint. With its robust design and unparalleled strength, this specialized joint has become the backbone of many heavy-duty applications, ensuring that mechanical systems operate smoothly under intense stress and extreme conditions.

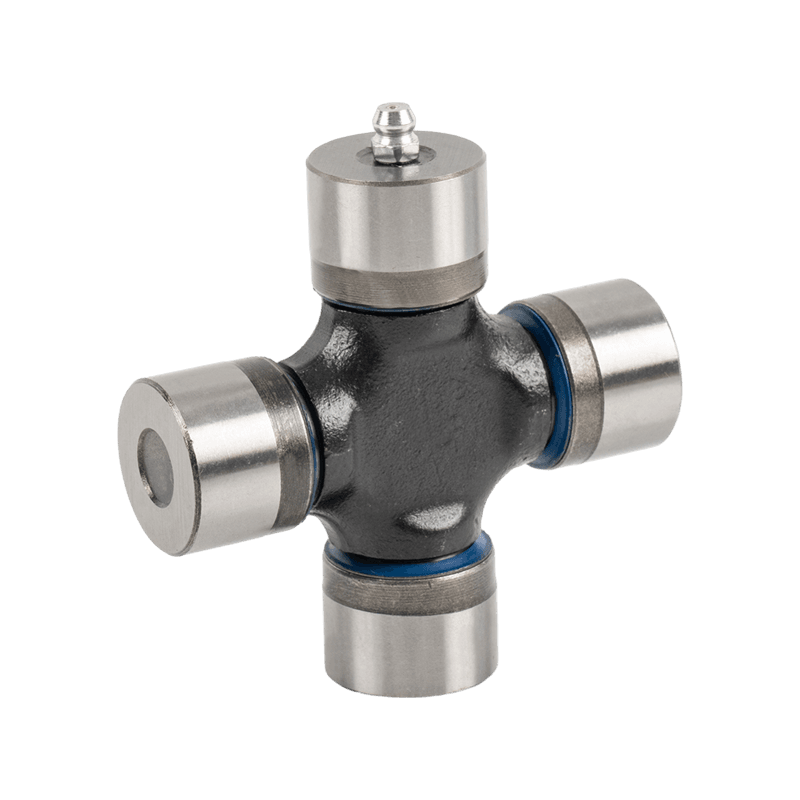

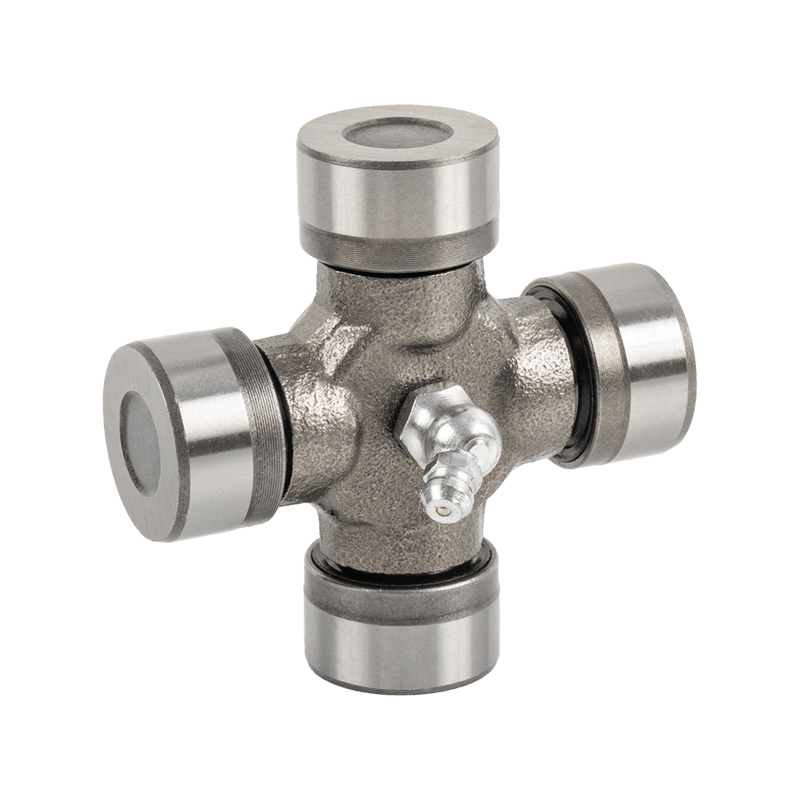

What is a 4 Welded Plate Type U-Joint?

A U-joint (or universal joint) is a mechanical component used to transmit rotary motion between two shafts that are not in line with each other. Typically used in automotive drivetrains, machinery, and industrial equipment, U-joints allow for changes in angle between the connected shafts, providing flexibility in power transmission.

The 4 welded plate type U-joint is a specific design of U-joint where four metal plates (typically made of high-strength steel or alloys) are welded together to form a robust, rigid, and durable joint. This construction method offers superior torsional strength, making it ideal for applications where traditional U-joints would fail due to excessive load, vibration, or heat.

The Role of 4 Welded Plate Type U-Joints in Heavy-Duty Applications

Heavy-duty machinery and industrial equipment are subjected to extreme conditions, such as high torque, constant vibrations, and exposure to abrasive environments. Whether in construction, mining, agriculture, or automotive applications, components must be capable of handling these challenges without compromising performance. This is where the 4 welded plate type U-joint excels.

Enhanced Strength and Durability

The most significant advantage of the 4 welded plate type U-joint is its exceptional strength and durability. Unlike traditional U-joints, which may use simpler materials or designs that can wear out over time, the welded plate construction provides superior torsional resistance. This is crucial in heavy-duty applications where machinery is often subjected to high forces that can cause standard joints to fail. The welded design ensures that the U-joint maintains its integrity even under intense loads, significantly extending the lifespan of the entire power transmission system.

Stronger Materials: High-strength steel or alloy materials used in 4 welded plate U-joints resist wear and tear, even in abrasive or harsh environments.

Vibration Resistance: The welded structure minimizes the risk of parts loosening or coming apart due to vibrations, a common problem in heavy-duty equipment.

Improved Performance in High-Torque Situations

Heavy-duty machinery often operates in high-torque conditions, especially during tasks like lifting, drilling, or pushing large loads. In these scenarios, traditional U-joints can struggle to handle the sheer force exerted on them, leading to breakdowns and costly downtime. The 4 welded plate type U-joint, however, is specifically designed to withstand these forces without compromising its ability to transfer power efficiently.

High-Torque Capacity: The welded plate structure offers higher resistance to rotational stress, making it ideal for high-torque environments such as hydraulic systems, industrial pumps, and automotive transmissions.

Improved Load Distribution: The robust design ensures that forces are evenly distributed across the joint, preventing localized wear and damage.

Ability to Withstand Extreme Conditions

In heavy-duty applications, components are often exposed to extreme environments, including heat, dust, moisture, and chemicals. A U-joint used in such conditions needs to be highly resistant to corrosion, oxidation, and fatigue. The welded plate construction is more resistant to these environmental factors than traditional U-joint designs.

Corrosion Resistance: The materials used in 4 welded plate type U-joints, combined with the welded construction, make them highly resistant to corrosion and abrasion, ensuring they can perform reliably in industries like mining, construction, and agriculture.

Heat Resistance: Many heavy-duty applications generate significant heat, especially in automotive and industrial systems. The welded plate U-joint can withstand high temperatures without deteriorating, ensuring continuous operation in heat-intensive environments.

Flexibility and Angle Compensation

Heavy-duty equipment often operates in dynamic environments where the angle between shafts can change frequently, especially in vehicles or machinery with suspended axles or rotating components. The 4 welded plate type U-joint provides greater flexibility than traditional designs, allowing for a wider range of motion while still maintaining a firm connection between shafts.

Wide Range of Angles: The design of the 4 welded plate type U-joint allows it to accommodate larger angular misalignments between the connected shafts, making it ideal for complex applications like off-road vehicles or agricultural machinery.

Smooth Power Transmission: Despite its ruggedness, the 4 welded plate U-joint offers smooth power transfer by allowing for slight shifts in the shaft angle without creating jerks or vibrations that could damage other parts of the system.

Reduced Maintenance Costs

One of the key advantages of the 4 welded plate type U-joint is its ability to reduce maintenance costs over the long term. Its robust construction and resistance to wear and tear mean that it requires less frequent servicing and is less likely to fail prematurely. This is crucial in industries where equipment downtime can result in significant financial losses.

Fewer Breakdowns: With its high strength and resistance to fatigue, the 4 welded plate U-joint is less likely to experience catastrophic failures, meaning fewer repairs and replacements.

Lower Operational Costs: Because the 4 welded plate U-joint extends the life of power transmission systems, businesses can save on maintenance and replacement costs while keeping machinery running smoothly.

Key Industries That Rely on 4 Welded Plate Type U-Joints

Given the durability, strength, and reliability of the 4 welded plate type U-joint, it is an essential component in several heavy-duty industries. Some of the most common industries that rely on these U-joints include:

Automotive

In the automotive industry, particularly for trucks, off-road vehicles, and heavy-duty equipment, the 4 welded plate U-joint plays a critical role in the drivetrain. Its ability to handle high torque and extreme conditions ensures that the vehicle can continue to perform optimally, even in challenging terrains or under heavy loads.

Construction

In construction machinery, such as excavators, cranes, and loaders, the 4 welded plate U-joint is essential for ensuring efficient power transmission between various moving parts. Its rugged design helps it withstand the heavy lifting, high-stress conditions, and vibrations common in construction work.

Agriculture

Farm equipment like tractors, harvesters, and plows needs to operate effectively in rough, unpredictable conditions. The 4 welded plate U-joint's durability and ability to handle fluctuating angles and heavy loads make it a preferred choice for agricultural machinery.

Mining and Heavy Industry

Mining machinery operates under some of the harshest conditions, with high levels of vibration, dust, and extreme mechanical stress. The 4 welded plate U-joint is designed to thrive in these environments, ensuring reliable power transmission for equipment like drills, haul trucks, and shovels.

English

English 中文简体

中文简体