The Hidden Advantages of 4 Wings Bearing U-Joints in Industrial Machinery

Content

In the world of industrial machinery, performance, reliability, and efficiency are non-negotiable. Every component, no matter how small, plays a crucial role in ensuring smooth operations and minimizing downtime. One such component that often goes unnoticed but holds significant importance is the 4 wings bearing U-joint. These mechanical components are designed to transmit torque and rotational motion efficiently while accommodating misalignment between shafts, making them indispensable in a variety of industrial applications.

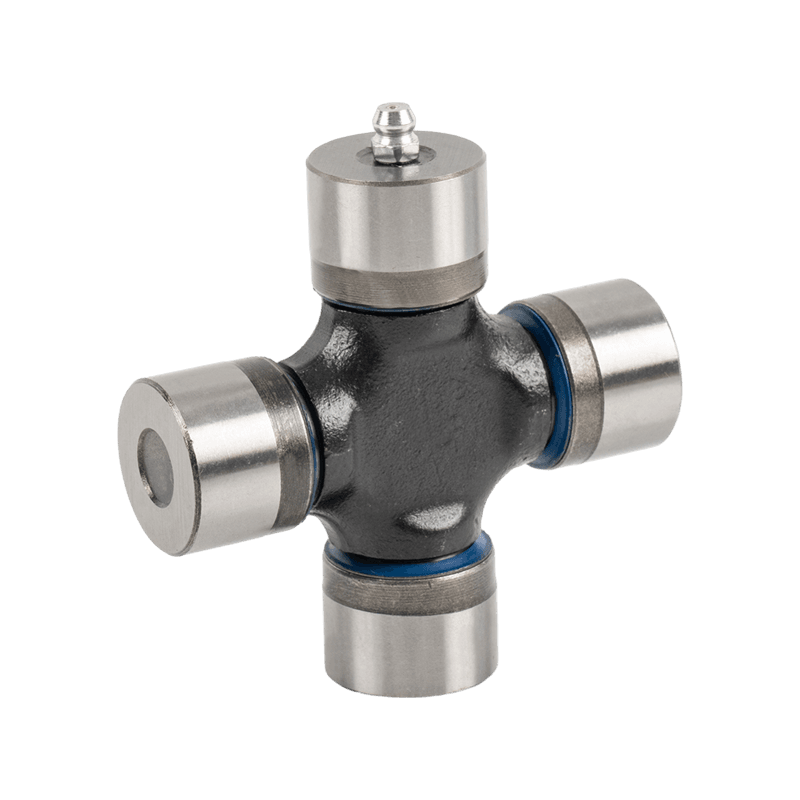

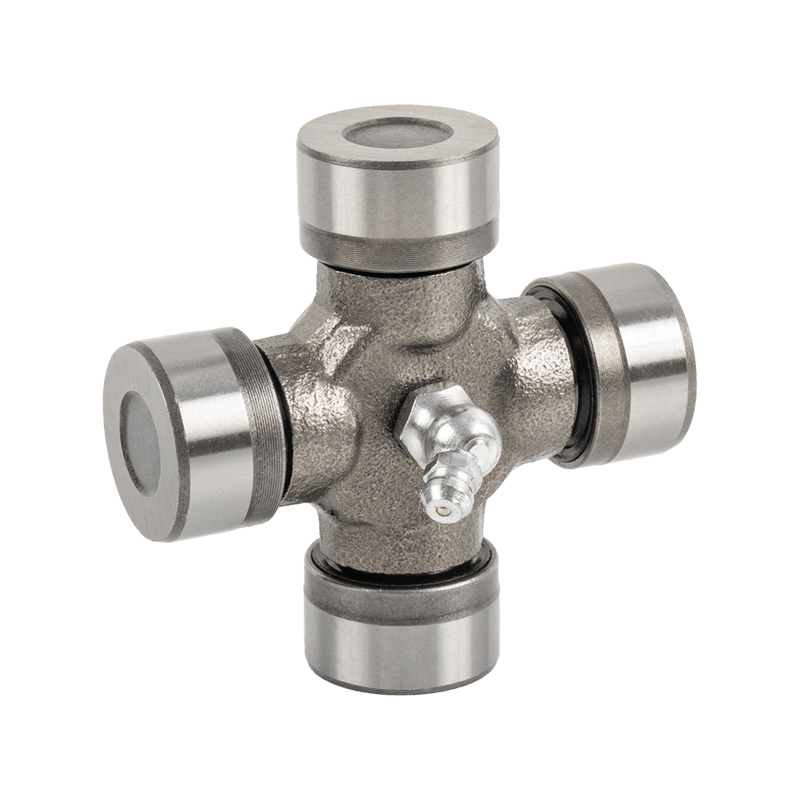

Understanding the 4 Wings Bearing U-Joint

A 4 wings bearing U-joint is a type of universal joint that features four bearing points arranged in a cross configuration, often referred to as a spider. This design allows the joint to flex and compensate for angular misalignment between connected shafts while maintaining torque transmission. Unlike traditional U-joints, the 4 wings bearing design distributes load more evenly across the bearings, reducing wear and extending the operational life of the machinery.

These joints are widely used in industrial equipment, automotive drive systems, agricultural machinery, and heavy-duty vehicles due to their robustness and adaptability. Their ability to handle high torque, coupled with durability under harsh conditions, makes them a preferred choice for engineers and maintenance professionals alike.

Key Advantages of 4 Wings Bearing U-Joints

Despite being a small component, the 4 wings bearing U-joint offers several hidden advantages that significantly enhance machinery performance and reliability.

Superior Load Distribution

The four-bearing design ensures that torque is evenly distributed across all contact points. This reduces stress concentrations that can lead to premature failure in traditional two-bearing U-joints. As a result, machinery equipped with 4 wings bearing U-joints experiences less vibration and wear, improving overall longevity.

High Torque Capacity

Industrial machinery often operates under extreme loads, requiring components that can handle substantial torque without compromising structural integrity. The 4 wings bearing U-joint excels in transmitting high torque efficiently, ensuring consistent performance even under demanding conditions. This capability is particularly valuable in heavy-duty applications such as conveyors, pumps, and industrial mixers.

Enhanced Flexibility and Misalignment Compensation

One of the most significant advantages of the 4 wings bearing U-joint is its ability to accommodate angular misalignment between shafts. In industrial setups, perfect shaft alignment is rarely achievable due to vibrations, thermal expansion, or structural constraints. By flexing without losing torque transmission, 4 wings bearing U-joints reduce stress on connected components, minimizing maintenance needs and downtime.

Reduced Maintenance Requirements

The even load distribution and robust design of 4 wings bearing U-joints contribute to lower wear rates compared to conventional U-joints. Many models also incorporate sealed bearings that prevent contamination from dust, debris, and moisture, further extending service life. Industrial operators benefit from longer intervals between maintenance cycles, reducing operational costs and improving efficiency.

Vibration Dampening and Noise Reduction

Excessive vibration in machinery can lead to structural fatigue, misalignment, and reduced precision. The 4 wings bearing U-joint helps dampen vibrations due to its balanced design, leading to smoother operation and lower noise levels. This feature is particularly important in industries where precision and consistent performance are critical, such as automotive assembly lines and CNC machinery.

Versatility Across Applications

4 wings bearing U-joints are highly versatile and adaptable to a wide range of industrial machinery. They are commonly used in:

Conveyor Systems: Ensuring smooth power transmission despite minor shaft misalignments.

Agricultural Equipment: Handling variable loads and harsh environmental conditions.

Automotive and Heavy Vehicles: Providing reliable torque transfer in drive shafts.

Pumps and Mixers: Allowing efficient operation with minimal downtime.

This versatility makes 4 wings bearing U-joints a standard component in modern industrial engineering.

Material and Design Innovations

Recent advancements in materials and manufacturing processes have further enhanced the performance of 4 wings bearing U-joints. High-strength alloys and precision machining improve fatigue resistance and durability. Some models now feature advanced lubricants or self-lubricating bearings that reduce maintenance requirements and extend operational life. Additionally, corrosion-resistant coatings make these U-joints suitable for outdoor and harsh industrial environments.

Design innovations, such as optimized cross geometries and reinforced bearing caps, improve load handling and reduce the risk of joint failure under extreme conditions. These enhancements ensure that 4 wings bearing U-joints remain a reliable and efficient choice for modern industrial machinery.

Maintenance and Installation Best Practices

Proper installation and maintenance are crucial for maximizing the benefits of 4 wings bearing U-joints:

Regular Inspection: Periodically check for signs of wear, misalignment, or lubrication failure.

Lubrication: Use recommended greases to maintain bearing performance, especially in high-load applications.

Alignment Checks: While 4 wings bearing U-joints tolerate misalignment, extreme deviations should be corrected to prevent unnecessary stress.

Clean Environment: Keep the joint free from debris and contaminants to prolong bearing life.

Following these best practices ensures that 4 wings bearing U-joints deliver optimal performance and minimize downtime.

Industry Impact

The adoption of 4 wings bearing U-joints has significantly influenced industrial efficiency. By reducing wear, vibration, and maintenance requirements, these joints help companies achieve higher productivity and lower operational costs. Their reliability under extreme conditions also allows machinery to operate longer without failure, supporting continuous production and minimizing interruptions.

Industries ranging from manufacturing and automotive to agriculture and heavy equipment rely on 4 wings bearing U-joints to maintain operational excellence. Their hidden advantages—often overlooked by end-users—play a crucial role in ensuring that machinery performs efficiently and safely.

English

English 中文简体

中文简体