How to Choose the Right Industrial Equipment Cross Kits to Improve Productivity?

Content

In modern industrial production, the efficient operation of equipment directly impacts a company's production efficiency and market competitiveness. Whether it's heavy machinery, precision instruments, or automated production lines, the proper functioning of each piece of equipment depends on precise components and supporting systems. During equipment maintenance and upgrades, industrial equipment cross kits, as one of the core components, play a crucial role in improving productivity, reducing downtime, lowering repair costs, and extending equipment life. Therefore, selecting the right cross kit is a crucial step for any company striving for efficient production.

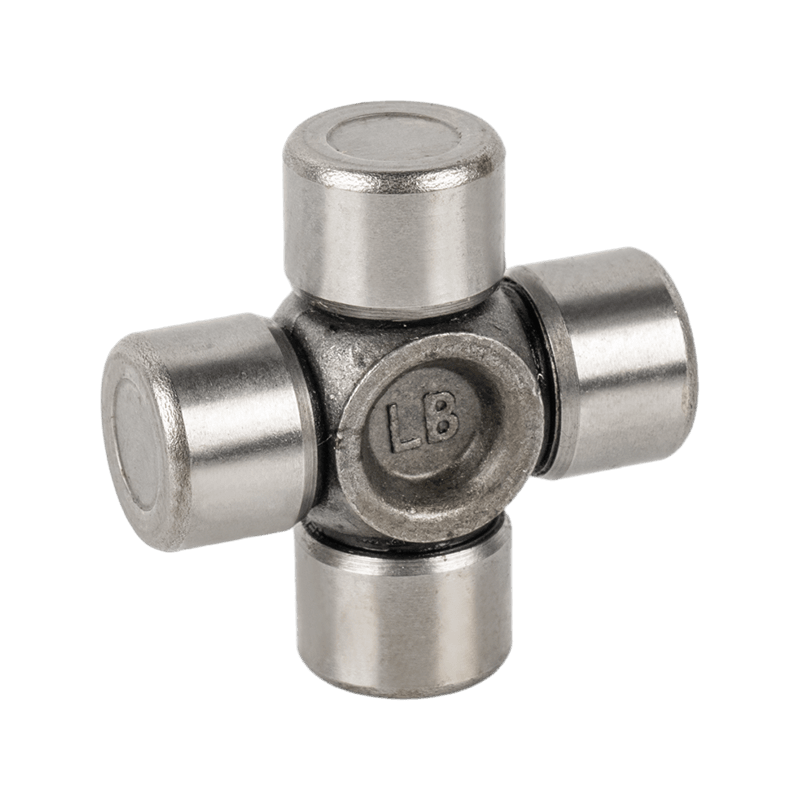

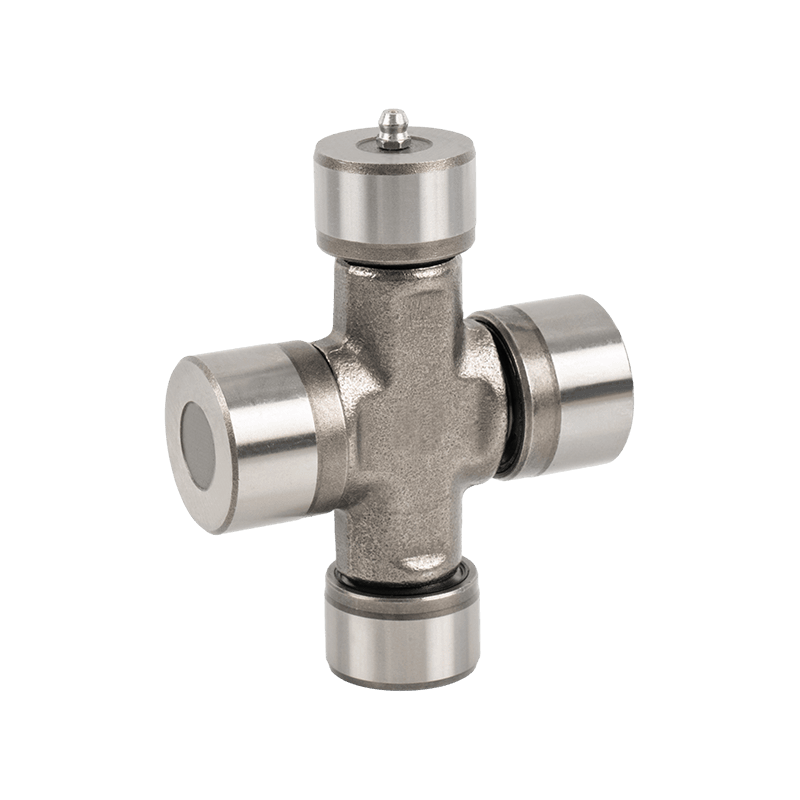

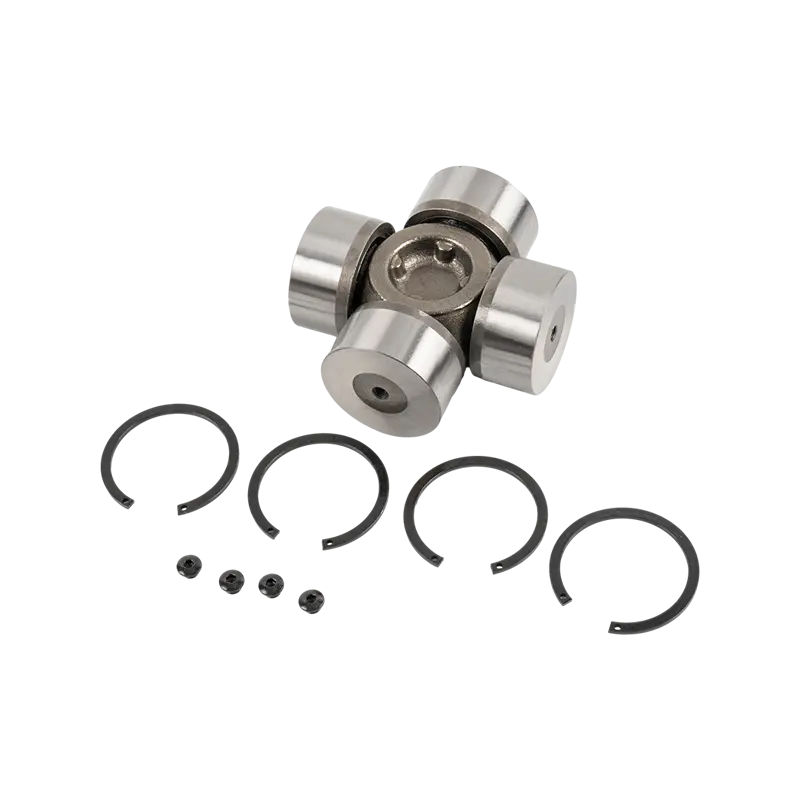

What are industrial equipment cross kits?

An industrial equipment cross kit is a collection of matching parts and components designed for a specific piece of industrial equipment or series of equipment. These components include seals, gaskets, bearings, gears, hydraulic pipes, drive belts, and more, designed to ensure efficient and stable operation under varying operating conditions. Compared to purchasing individual parts, a cross kit integrates multiple essential key components into a complete solution. It meets the needs of routine equipment maintenance, quick repairs, and parts replacement, reducing redundancy in the procurement process, streamlining management processes, and improving overall efficiency.

How to Choose the Right Industrial Equipment Cross Kits?

Choosing the right industrial equipment cross kits directly impacts equipment stability, production efficiency, and cost control for your company.

Equipment Operating Conditions and Usage Environment

Each piece of equipment has different operating environments and usage conditions. When selecting a cross kit, you must first understand the equipment's operating conditions and environment. For example, hydraulic systems and heavy machinery may operate in high temperatures, high pressures, or harsh environments. Cross kits for these devices require properties such as high-temperature resistance, corrosion resistance, and oxidation resistance. Conversely, precision instruments and electronic equipment require high-precision components that are resistant to static electricity and interference. Therefore, adapting to environmental requirements is the first step when selecting a cross kit.

For example, equipment operating in highly corrosive environments may require seals and piping with corrosion-resistant properties. Equipment operating in extremely cold or high-humidity environments requires materials that can operate normally in these conditions. These are factors that require special consideration when selecting crossover kits.

Matching Equipment Type and Specifications

Each piece of equipment has specific specifications and technical requirements, and the crossover kit selected must match the equipment's model, specifications, and functionality. For example, the size, strength, and durability requirements of components in a crossover kit for a large electric motor and a small precision instrument are completely different. To ensure the effectiveness of a crossover kit, components that precisely match the equipment's model and functionality must be selected based on the equipment's operating requirements.

When selecting a crossover kit, companies need to thoroughly understand the equipment's technical specifications, including power, speed, and load, and ensure that the selected crossover kit can withstand these operating conditions. For example, crossover kits for heavy machinery and engineering equipment often require stronger vibration and high-temperature resistance, while precision equipment requires components that offer high precision and low wear.

Quality and Reliability of Crossover Kits

Quality and reliability are among the most critical factors when selecting crossover kits. Industrial equipment often operates under high loads and high stress. A single component failure can cause equipment downtime and impact production efficiency. Therefore, selecting high-quality, reliable crossover kits can significantly reduce equipment failures and extend their lifespan.

High-quality crossover kits typically comply with international standards and industry certifications, such as ISO, ANSI, and DIN, ensuring proper functioning even in extreme environments. Furthermore, highly reliable crossover kits reduce maintenance frequency and costs, ensuring continuous production line operation.

When selecting a crossover kit, companies should prioritize suppliers with rigorous quality control, a strong market reputation, and strong technical support. Especially for high-risk, demanding equipment maintenance, choosing reputable suppliers can ensure the quality and long-term reliability of the crossover kit.

Cost-Effectiveness and Economical Efficiency

Although high-quality crossover kits are often more expensive, their longer lifespan and lower failure rate can effectively reduce long-term maintenance costs and lead to higher production efficiency. Therefore, when selecting a crossover kit, companies should not simply consider the initial purchase cost but instead conduct a comprehensive assessment from the perspective of lifecycle costs.

By choosing cost-effective crossover kits, companies can not only reduce procurement costs but also minimize equipment downtime and repair costs. Furthermore, using efficient and reliable crossover kits can significantly improve production efficiency and reduce production losses due to equipment failure, thereby creating higher economic benefits for the company.

Comparing kits from different brands and specifications, companies can select the crossover kit that offers the best balance of quality, performance, and price. For example, a standardized crossover kit might be suitable for certain equipment, while a customized kit with superior performance might be suitable for high-end equipment or critical production lines.

Supplier Service and Support

The quality of a supplier's service and support is directly related to the effectiveness of the crossover kit and the company's production efficiency. Excellent suppliers not only provide high-quality crossover kits but also offer timely technical support and solutions when equipment issues arise.

Selecting a supplier with strong technical support and after-sales service capabilities can help companies quickly identify the problem when equipment fails, avoiding prolonged downtime. Especially when equipment encounters complex issues during operation, timely and professional technical service is crucial to restoring production.

Whether the supplier can provide rapid spare parts supply and replacement services is also a key consideration when selecting a crossover kit. Especially during high-demand seasons, rapid spare parts availability can effectively mitigate the risk of equipment downtime due to parts shortages.

Customization vs. Standardization Requirements

Depending on the specific needs of the equipment, industrial equipment crossover kits can be either standardized or customized. For most general equipment, standardized kits generally meet the requirements, offer shorter lead times, and are more economical. However, for specialized environments, operating conditions, or equipment, customized kits may be required.

Customized crossover kits can be tailored to the equipment's operating characteristics, loads, and operating environment, ensuring that every component is perfectly matched to the equipment's requirements. While customized kits may be more expensive, they offer higher performance and a longer service life. For critical equipment, customized kits are often the more ideal choice.

English

English 中文简体

中文简体