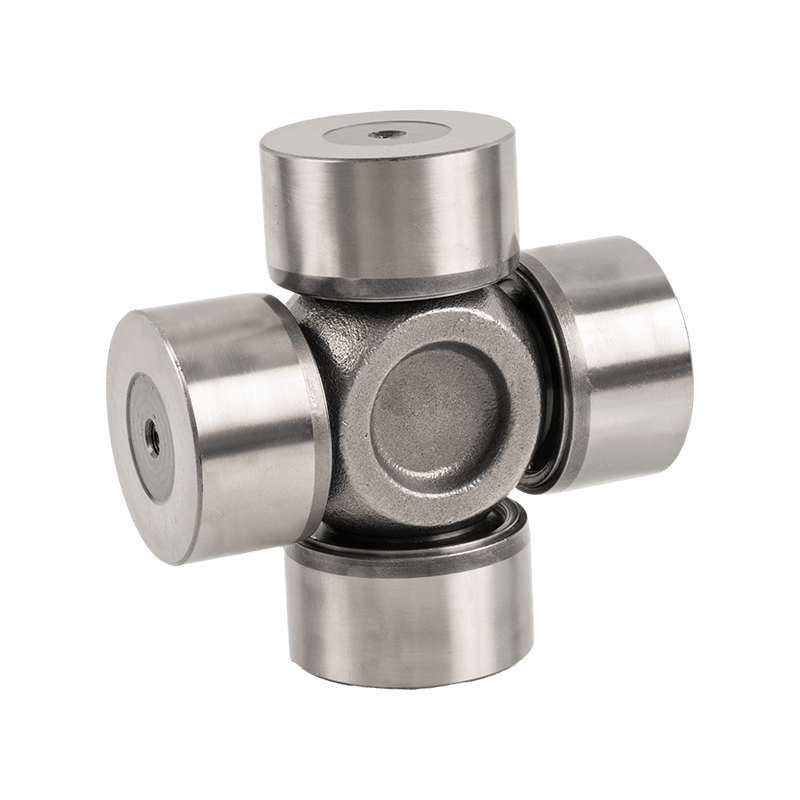

How to Improve Durability and Efficiency with a U-Joint with Two Plain and Two Grooved Round Bearings

Content

In modern mechanical transmission systems, U-joints, as a key connecting component, are widely used in a variety of equipment and systems requiring efficient power transmission. Whether in automobiles, industrial machinery, or agricultural equipment, U-joints play a vital role. With the continuous advancement of technology and increasing performance requirements, traditional U-joint designs face increasing challenges. Especially in high-load, high-speed operating environments, improving the durability and efficiency of the joint has become a key focus for engineers. As an innovative design, the U-joint with two plain and two grooved round bearings, with its unique structural advantages, is significantly improving the performance of mechanical transmission systems.

Design Advantages of the U-joint with Two Plain and Two Grooved Round Bearings

The U-joint with two plain and two grooved round bearings offers several significant advantages over traditional U-joints, primarily in terms of increased load capacity, reduced friction loss, and extended service life.

Combination of Plain and Grooved Bearings

Traditional U-joints typically utilize a single plain or round bearing. While this design can meet basic load requirements, it is prone to excessive wear and seizure under high loads and high speeds. The U-joint with two plain and two grooved round bearings significantly enhances the joint's load capacity and durability through its dual bearing combination.

Plain bearings typically provide a smooth friction surface, effectively reducing deflection caused by lateral loads and ensuring rotational accuracy and stability.

Grooved round bearings can better withstand loads from various directions. Especially during rotation, the groove design effectively distributes pressure and avoids localized overload.

This bearing combination not only provides excellent support under static loads but also effectively reduces friction and wear under dynamic loads, ensuring long-term stable operation of the joint.

Improved Friction Control and Vibration Reduction

Friction is one of the largest sources of energy loss in mechanical systems. Excessive friction, especially in high-load environments, accelerates component wear and reduces efficiency. The u-joint with two plain and two grooved round bearings effectively controls friction and minimizes frictional losses through optimal bearing design.

The grooved bearing design also acts as a shock absorber, absorbing and dissipating vibration and impact forces generated during operation, reducing load fluctuations within the mechanical system and extending the service life of other components.

Improved Stability and Reliability

Traditional U-joints are prone to axial displacement and misalignment due to a lack of effective bearing support, which compromises system stability. The u-joint with two plain and two grooved round bearings, however, effectively prevents axial and radial misalignment through precise bearing alignment, maintaining system stability. This significantly improves joint reliability, reduces equipment failure rates, and lowers maintenance costs.

Corrosion and High-Temperature Resistance

Under extreme operating conditions, U-joints must not only withstand high loads and high speeds but also possess corrosion and high-temperature resistance. U-joints with two plain and two grooved round bearings are typically made of high-strength alloy steel and a special high-temperature and corrosion-resistant coating. This ensures stable operation in harsh environments and extends their service life.

Improving Durability and Efficiency

Reducing Wear and Prolonging Service Life

U-joints with two plain and two grooved round bearings effectively control friction. The combination of plain and grooved round bearings distributes friction more evenly during rotation, avoiding the localized wear associated with traditional U-joints due to excessive friction concentration. This design significantly reduces bearing wear and improves the durability of the U-joint.

Under high loads or high-speed operation, U-joints with dual bearings can better withstand external pressure, maintain stable operation, and reduce failures caused by friction and wear, thereby extending the overall service life of the machinery.

Improving Transmission Efficiency and Reducing Energy Consumption

The energy efficiency of machinery is a key factor in determining its economic and environmental performance. Traditional U-joints, due to their high friction and low transmission efficiency, often waste unnecessary energy. The U-joint with two plain and two grooved round bearings improves power transmission efficiency by reducing frictional losses. Under the same load and speed, this U-joint effectively minimizes energy loss, resulting in more efficient power transmission and lower energy consumption.

This efficient power transmission not only improves machine efficiency but also reduces operating costs, which is particularly important for equipment subject to long periods of high load operation.

Reduced Maintenance and Downtime

The reliability of the U-joint directly impacts the normal operation of the equipment. The U-joint with two plain and two grooved round bearings significantly enhances system stability and interference resistance, reducing maintenance and downtime caused by joint failures. This is particularly important for industrial equipment that requires efficient operation. By improving joint durability, the overall equipment uptime is extended, thereby improving production efficiency.

Optimized Design, Enhanced Overall Performance

The U-joint with two plain and two grooved round bearings improves the system's load capacity and operating stability, reduces the burden on other components, and optimizes the overall machine design. Especially in complex mechanical transmission systems, the improved performance of U-joints can significantly improve the dynamic response speed and operating smoothness of the entire machine, enhancing the overall performance of the entire system.

In high-precision equipment and high-load machines, the use of this U-joint can effectively enhance the stability and response speed of the equipment, allowing the equipment to maintain efficient operation under complex working conditions.

Application Areas

1. Automotive Industry: In automotive manufacturing, U-joints are a critical component of the drive system. U-joints with two plain and two grooved round bearings can effectively improve the durability and efficiency of automotive drivetrains. This is especially true in high-performance vehicles and commercial vehicles, which are subject to high loads. This innovative U-joint design improves vehicle stability and power transmission efficiency.

2. Industrial Machinery: U-joints play a vital role in power transmission in various industrial machinery, especially heavy machinery, mining equipment, and agricultural machinery. U-joints with two plain and two grooved round bearings are an ideal choice for these applications due to their exceptional durability and efficiency.

3. Agricultural and Construction Equipment: Modern agricultural and construction equipment often needs to handle significant mechanical loads during operation. U-joints with dual bearings offer increased load-bearing capacity and a longer service life, making them particularly suitable for heavy equipment such as tractors and excavators.

English

English 中文简体

中文简体