The Widespread Application and Future Development of U-Joints with Four Plain Round Bearings in Industrial Machinery

Content

In modern industry, with the continuous advancement of mechanical technology, key components in power transmission systems are undergoing continuous innovation and upgrading. Among them, the U-joint with four plain round bearings, as a highly efficient power transmission component, has been widely used in various industrial machinery due to its outstanding durability, load-bearing capacity, and stability, achieving remarkable results in multiple fields. With the continuous advancement of industrial automation and mechanization, the application scope of the U-joint with four plain round bearings is continuously expanding, and its future development prospects are promising.

Basic Principles and Features of the U-joint with Four Plain Round Bearings

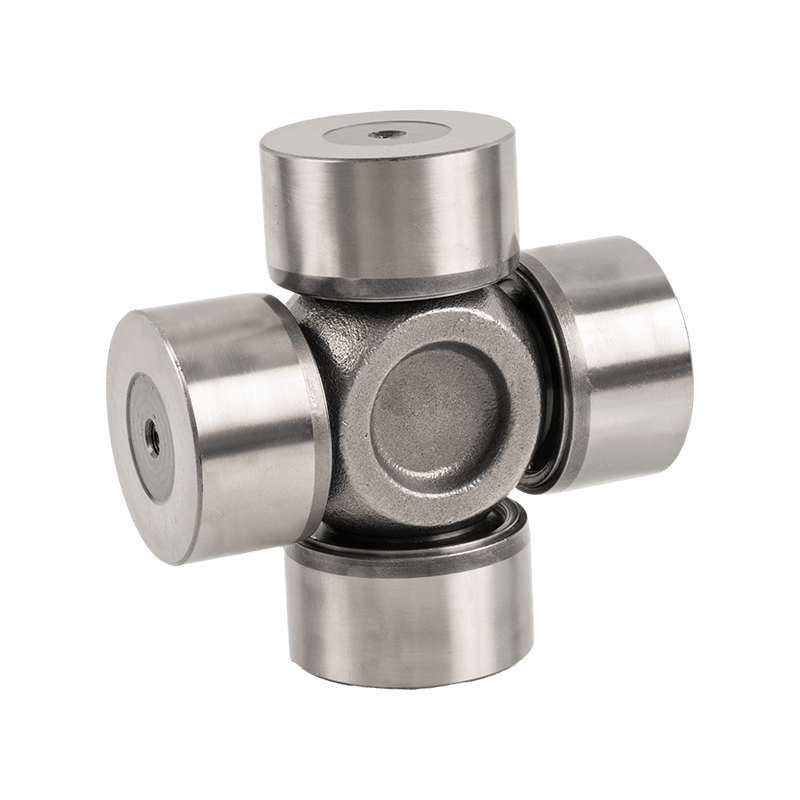

As the name suggests, the U-joint with four plain round bearings is a cross-shaped connector composed of four plain round bearings. This design offers significant advantages over traditional two-bearing cross shafts (common in early U-joints) in terms of load capacity, stability, and lifespan. The U-joint with four plain round bearings enables it to withstand higher loads during transmission and effectively reduces friction and wear, thereby improving the overall performance of mechanical equipment.

1. Strong Load-Carrying Capacity: The four-bearing design provides more support points, which means it can maintain stable operation for longer periods of time under high loads. Even under high loads and high speeds, the U-Joint with four plain round bearings maintains efficient power transmission, reducing failures and wear.

2. Durability and Reliability: Thanks to its use of high-quality materials and precision manufacturing, the U-Joint with four plain round bearings offers a longer service life than conventional two-bearing cross shafts. Especially in harsh operating environments, the four-bearing design effectively reduces damage caused by vibration, impact, and friction, ensuring the reliability of the equipment over extended periods of operation.

3. Strong Adaptability: The U-Joint with four plain round bearings is highly adaptable to a variety of industrial environments. Whether in high or low temperatures or in humid environments, this joint maintains excellent performance. Therefore, it is widely used in industries such as metallurgy, mining, agriculture, and transportation.

Widespread Application of U-Joints with Four Plain Round Bearings in Industrial Machinery

Due to their excellent performance, U-Joints with Four Plain Round Bearings have become an indispensable core component in a wide range of industrial machinery.

Automotive and Transportation Industry

U-Joints with Four Plain Round Bearings are particularly important in automobiles and transportation equipment. They are commonly used in key areas such as drive shafts, drive axles, and steering systems. With the development of the automotive industry, especially the rise of electric and smart cars, the requirements for power transmission systems are becoming increasingly stringent. U-Joints with Four Plain Round Bearings, with their efficient power transmission and durability, have become a vital component in modern automotive manufacturing.

In heavy-duty transportation vehicles such as commercial vehicles, trucks, and trailers, U-Joints with Four Plain Round Bearings also play a vital role in ensuring stability and reliability under high loads and high speeds.

Agricultural Machinery

Agricultural machinery operates under high loads and often faces complex and changing working environments. U-joints with four plain round bearings are widely used in agricultural machinery, such as tractors, combine harvesters, and seed drills. They effectively ensure continuous and stable power transmission during tillage, harvesting, and transportation, reducing the frequency of mechanical failures and improving operational efficiency.

In modern agricultural equipment, the high load capacity and long service life of U-joints with four plain round bearings significantly improve the overall durability of the equipment, reduce the frequency of repairs and replacements, and lower production costs.

Mining and Metallurgical Equipment

Mining and metallurgical equipment often operates in harsh environments, subjecting them to significant vibration, shock, and high temperatures. Under these operating conditions, the superior performance of U-joints with four plain round bearings is particularly prominent. They can operate stably and for extended periods under high loads, extreme temperatures, and harsh environments, ensuring the normal operation of the equipment.

For example, conveyor belt systems in mining machinery and rolling mills in metallurgical plants commonly use U-joints with four plain round bearings to improve the reliability and efficiency of the drive system. These devices place extremely high demands on power transmission. U-joints with four plain round bearings ensure smooth power transmission during high-intensity operations, reducing equipment failure rates.

Construction Machinery

U-joints with four plain round bearings are widely used in the transmission systems of large machinery such as cranes, concrete mixers, and excavators in construction and road construction. With the rapid development of the construction industry, the demands placed on construction machinery are becoming increasingly stringent. Especially under high-intensity and high-load working conditions, U-joints with four plain round bearings provide powerful power support, ensuring stable operation.

Future Development Trends of U-joints with Four Plain Round Bearings

With continuous technological advancements, the design and application of U-joints with four plain round bearings are evolving towards greater efficiency and intelligence.

1. Higher Load Capacity and Durability: As the demands placed on power transmission systems in machinery and equipment continue to rise, the load capacity and durability of U-joints with four plain round bearings will continue to increase. By utilizing higher-strength alloy materials and advanced heat treatment technology, the u-joint with four plain round bearings will be able to withstand higher loads and harsh environments, ensuring stable operation of industrial machinery under extreme conditions.

2. Intelligence and Automation: Future u-joints with four plain round bearings will be integrated with intelligent systems, possessing enhanced adaptability. For example, utilizing sensor technology, the u-joint with four plain round bearings can monitor its operating status in real time, promptly detecting any anomalies and preventing mechanical failures. This intelligent cross-axle will better meet the needs of modern automated production lines and smart manufacturing.

3. Lightweighting and Energy Saving: With increasing industrial demands for energy conservation and environmental protection, lightweighting of u-joints with four plain round bearings will become a key development direction. Through optimized design and the use of new high-strength, lightweight materials, u-joints with four plain round bearings can reduce the weight of the entire machinery without sacrificing load-bearing capacity and stability, thereby improving energy efficiency and lowering transportation costs.

4. Sustainable Development and Eco-Friendly Design: Environmental protection has become a key issue in the global industrial landscape. Future development of the u-joint with 4 plain round bearings will prioritize the environmental friendliness of materials. By utilizing recyclable materials, reducing the use of hazardous substances, and improving production processes, the u-joint with 4 plain round bearings will develop in a more environmentally friendly and sustainable direction, in line with the global trend toward green manufacturing.

English

English 中文简体

中文简体