Komatsu U-Joint Applications in Modern Machinery

Content

In modern heavy machinery, reliability and high efficiency are key factors for the long-term, stable operation of any piece of equipment. As a world-renowned heavy machinery manufacturer, Komatsu occupies a prominent position in the industry with its precision design, performance, and high durability. The U-Joint, a key component, plays a crucial role in Komatsu equipment. It is not only a vital component connecting the power system but also directly impacts the equipment's efficiency and stability. In particular, in various heavy machinery applications, the Komatsu U-Joint, with its technological advantages, ensures the equipment's performance under various operating conditions.

Basic Functions of the Komatsu U-Joint

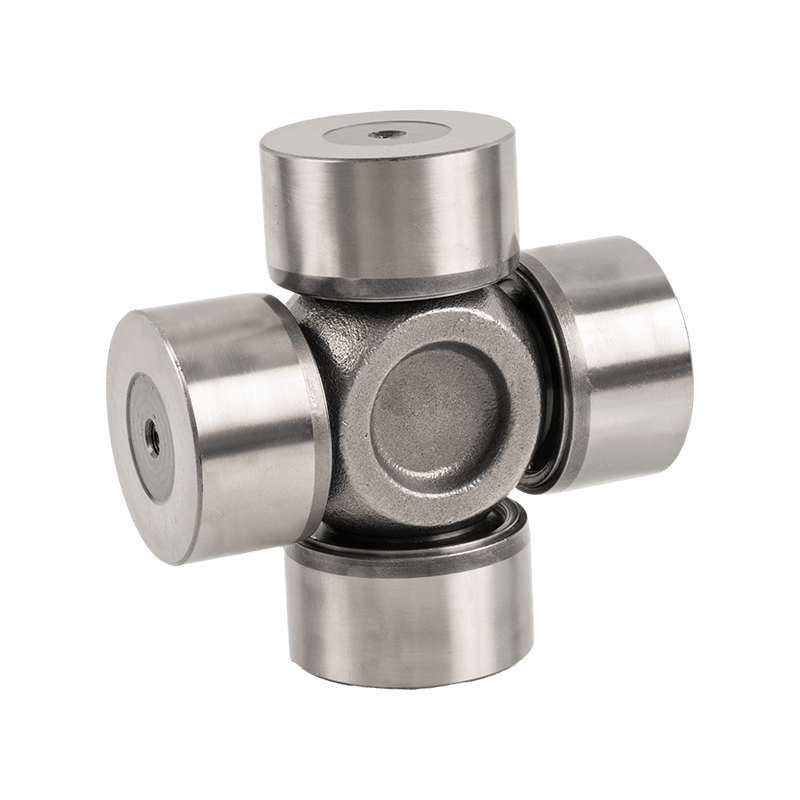

As a crucial connection device in mechanical systems, the U-Joint is primarily used to connect two rotating components to transmit power at different angles. It ensures smooth operation of the power system and prevents failures caused by loose or unstable connections between equipment components. For construction machinery, the stability of the U-Joint directly affects the efficiency of power transmission and the equipment's workload.

Across Komatsu's various heavy-duty machinery, from bulldozers and excavators to loaders and mining equipment, U-Joints play a crucial role in power transmission within the mechanical system. Their high strength and wear resistance enable them to provide continuous and stable power support in complex and demanding environments, ensuring smooth operation under a wide range of operating conditions.

Applications of Komatsu U-Joints in Heavy Machinery

Applications in Construction Machinery

The construction industry places extremely high demands on the reliability of machinery, especially in complex construction sites. Machinery must not only withstand various high-intensity operations but also endure harsh climates and terrains. Komatsu excavators, bulldozers, loaders, and other construction machinery often operate for extended periods on uneven terrain, in muddy worksites, or under extremely high loads. U-Joints are particularly crucial in these situations.

The Komatsu U-Joint's high-strength materials and precision machining enable it to withstand the enormous loads and impacts of these diverse environments while ensuring efficient and stable power transmission. Especially under high-load conditions, the U-Joint effectively reduces downtime caused by component damage, helping equipment maintain long-term stable operational capabilities. Therefore, the efficiency and reliability of construction machinery largely depend on the high performance of the U-Joint.

Applications in Mining Machinery

Mining environments are extremely harsh, with equipment subject to extensive exposure to dust, dirt, moisture, and other corrosive factors, while also handling high workloads. Komatsu uses the U-Joint as a core component in mining machinery, ensuring stable power output in these environments.

Whether it's large-scale mining bulldozers, drilling equipment, or transport machinery, the Komatsu U-Joint provides reliable power transmission. Especially in mining, where equipment often needs to maintain high efficiency under load, the U-Joint withstands shock and load while providing stable power transmission, ensuring the equipment completes its mission smoothly.

The corrosive nature of mining environments also requires the U-Joint to possess corrosion resistance. The Komatsu U-Joint utilizes corrosion-resistant materials and coatings to effectively reduce wear and extend service life, even in humid or dusty environments. This is particularly important in the mining industry, where mining equipment often faces harsh environments, and equipment stability directly impacts operational continuity and safety.

Application in Agricultural Machinery

Modern agricultural machinery, particularly tractors and combine harvesters, often requires high power support and stable mechanical performance for large-scale tillage, harvesting, and transportation. The Komatsu U-Joint, used in these agricultural machines, provides robust power transmission, enabling efficient field operations.

Agricultural machinery operates in complex environments, with uneven terrain and long working hours. Harvest season, in particular, places heavy loads on machinery, requiring constant, long-duration operation. The Komatsu U-Joint not only withstands these high-load conditions but also maintains stable operation in environments such as mud and dust. Its wear and corrosion resistance ensures long-term, stable operation of agricultural machinery in various weather conditions, reducing equipment failure rates and downtime.

Applications in Transportation and Logistics Equipment

U-Joints, as key components connecting different parts of heavy-duty transport vehicles and container handling equipment, play a vital role. Transport equipment is subject to long hours and high-intensity operation, requiring its powertrain to maintain high stability. Komatsu U-Joints, with their precision design and durable materials, ensure stable power transmission even during overload conditions, preventing equipment downtime or power loss due to U-Joint failure.

The transportation industry places extremely high demands on equipment reliability, especially in highway or long-distance transport, where even minor failures can result in significant losses. The Komatsu U-Joint's high performance ensures stable operation in a variety of complex transport environments, safeguarding efficient and safe logistics.

Technical Advantages of Komatsu U-Joints

The Komatsu U-Joint's application in heavy machinery goes beyond traditional design and craftsmanship; its technological advantages determine its performance in a variety of harsh working environments. By utilizing high-strength alloy materials, precision machining, and a wear- and corrosion-resistant design, the Komatsu U-Joint surpasses similar products in performance. Its resistance to high temperatures, corrosion, and fatigue enables it to provide stable power support in challenging environments.

The Komatsu U-Joint's high durability, low maintenance requirements, and outstanding efficiency have made it an indispensable component of numerous equipment in the construction, mining, agriculture, and transportation industries. Through technological innovation, Komatsu ensures that its U-Joint maintains high performance and reliability in a variety of operating conditions, reducing maintenance costs and downtime.

English

English 中文简体

中文简体