Common Misconceptions About Tractor Universal Joint Installation and Maintenance

Content

Tractors are essential power tools in agricultural production, and universal joints, one of their core components, play a crucial role in power transmission. By connecting the powertrain and working parts, universal joints ensure stable and efficient tractor operation in a variety of operating environments. Therefore, proper installation and regular maintenance are crucial to extending the tractor's service life and improving its efficiency.

Basic Function and Working Principle of the Tractor Universal Joint

The universal joint is a key component that connects the tractor's mainframe to the tractor's attachments (such as plows and tillers). It primarily compensates for angular misalignment of the drive shaft caused by changes in operating angle during power transmission, thereby ensuring smooth power transmission.

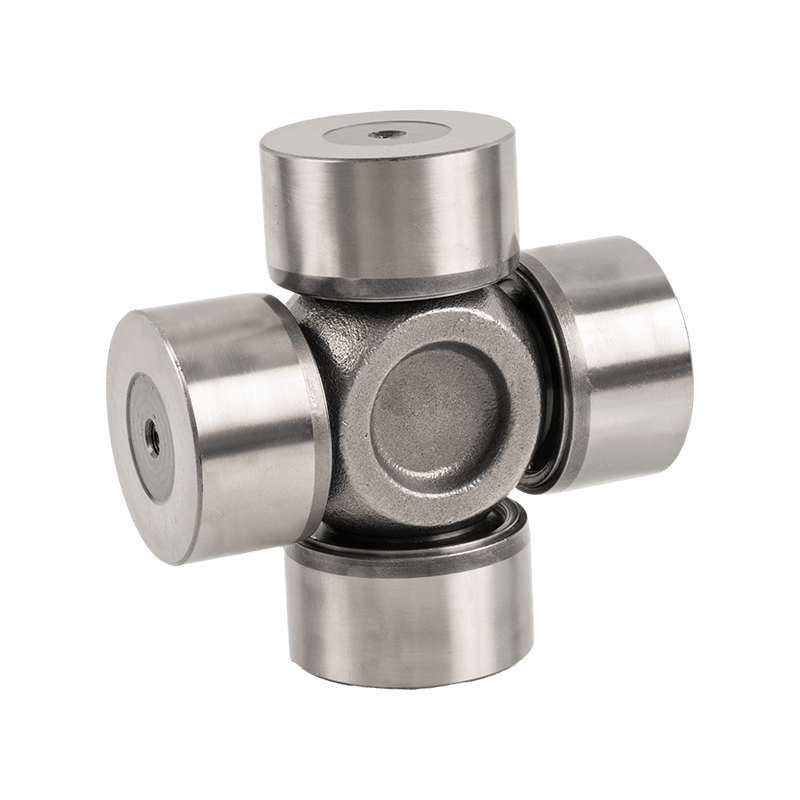

The tractor universal joint consists of two main components: the cross shaft and the universal joint arm. The cross shaft connects the tractor's power output shaft to the input shaft of the attachment. When the tractor turns or changes angle, the universal joint ensures efficient power transmission, preventing power interruption or transmission failure caused by incorrect angles.

Tractor Universal Joint Installation Mistakes

Ignoring the Universal Joint Installation Angle

When installing a universal joint, many operators often overlook the angle between the ends of the joint. During installation, it is crucial to ensure that the ends of the joint are at the proper angle to the tractor's powertrain. Incorrect installation angles can cause uneven power transmission during operation, and even lead to vibration, noise, and increased wear.

Correct Method: During installation, ensure that the axes of the two ends of the universal joint remain as parallel as possible and that the angles are correct. Manufacturers typically provide specific angle standards for different tractor models, and operators should strictly adhere to these standards during installation.

Using the Inappropriate Universal Joint Model

Many farmers and technicians often replace universal joints that do not meet the original tractor specifications. While universal joints from different brands and models may appear similar, their internal design standards and dimensions vary significantly. Using an inappropriate universal joint model will result in an inaccurate powertrain match, which in turn affects the stability of the entire transmission system.

Correct Practice: When replacing a universal joint, operators should select a universal joint compatible with the tractor based on the specific tractor model, the manufacturer's technical specifications, and the operating instructions. Avoid using low-quality or incompatible substitutes.

Neglecting Universal Joint Lubrication

Lubrication is crucial for ensuring the proper operation of universal joints. Many operators neglect to lubricate the universal joint during installation or use an unsuitable lubricant. This improper operation can cause excessive wear on the internal components of the universal joint, increase friction, and shorten the service life of the universal joint.

Correct Practice: Before installing the universal joint, ensure that the universal joint's cross shaft and arm are fully lubricated to ensure an adequate layer of lubricant between all components. Select a lubricant that meets the manufacturer's specifications and refill and replace it regularly according to the recommended intervals.

Failure to Check Component Condition Before Installation

When installing a universal joint, many operators proceed directly without inspecting other related drivetrain components. This can cause the universal joint to mismatch with other components after installation, leading to malfunction or failure.

Correct: Before installing the universal joint, thoroughly inspect all joint connections, the drive shaft, the cross shaft, and other components to ensure they are intact and free of excessive wear. Especially when replacing a new universal joint, check the universal joint bracket for integrity and any loose fasteners to ensure proper compatibility.

Tractor Universal Joint Maintenance Misconceptions

Neglecting Regular Inspection and Maintenance

Many operators only inspect and repair universal joints when problems arise, neglecting routine maintenance. Universal joints are susceptible to wear or loosening after long-term use due to factors such as the operating environment, vibration, and temperature. Regular inspection and maintenance can detect potential problems early and prevent more serious problems.

Correct Practice: Regularly inspect the universal joint connection, lubrication, and any signs of wear. Operators should especially thoroughly inspect the universal joint around the busy farming season to ensure it is in working order.

Not Replacing Worn Parts on Time

Overtime use of tractors can cause wear to components such as the universal joint's cross shaft and bearings. Many operators often wait until obvious problems occur before replacing them, leading to unstable power transmission and increased noise.

Correct Practice: Operators should regularly replace worn parts according to the maintenance schedule specified in the manual. If the universal joint makes unusual noises or vibrates excessively, inspect and replace severely worn parts immediately to avoid further damage.

Overlubrication or Use of Inappropriate Lubricant

Overlubrication or use of an inappropriate lubricant during maintenance can have adverse consequences. Excessive lubrication can cause oil to accumulate around the universal joint, attracting dust and impurities, accelerating component wear. Using substandard lubricant can result in poor lubrication and even damage the universal joint.

Correct: Use lubricant that meets the manufacturer's specifications and lubricate according to the recommended amount. Avoid using too much or too little lubricant to ensure effective lubrication while preventing other negative effects.

Neglecting to Clean the Universal Joint

Universal joints can easily accumulate dust, dirt, and other impurities during use. These impurities can affect lubrication, increase friction, and even cause wear. Many operators neglect to clean the joints properly.

Correct: When performing universal joint maintenance, operators should promptly remove dirt and impurities from the joint surface to ensure proper operation. After cleaning, re-lubricate the joint and ensure that there is no dust accumulation around the joint to extend its service life.

English

English 中文简体

中文简体