Exploring the Manufacturing Process and Design of the China Cardan Joint

Content

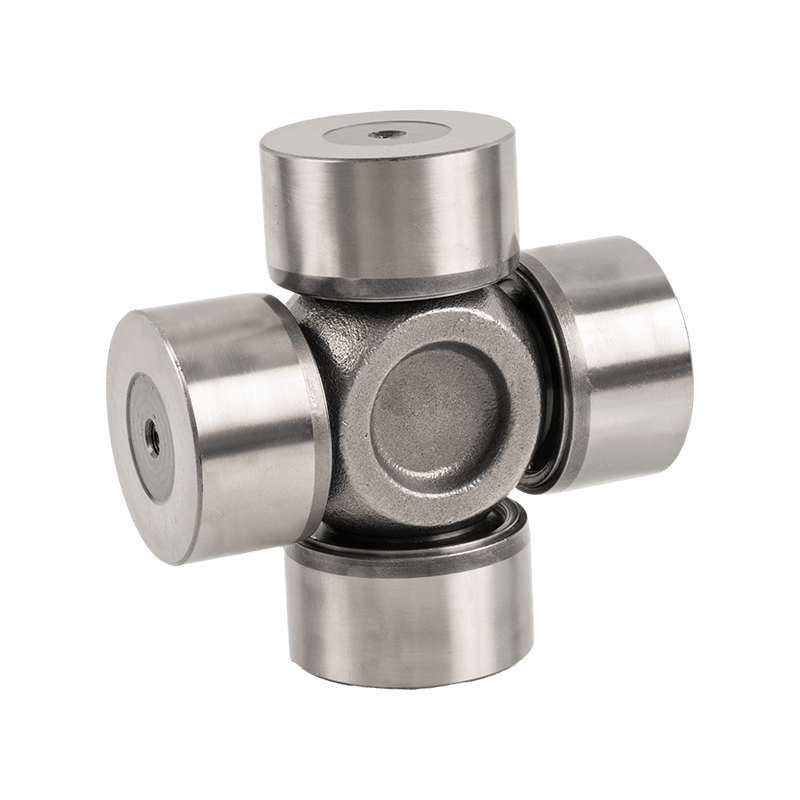

The Cardan joint, also known as a universal joint, is a mechanical transmission component widely used in a variety of applications, including automobiles, industrial machinery, and agricultural equipment. With the rapid development of China's manufacturing industry, China Cardan joint manufacturing technology continues to innovate, gradually gaining a significant position in the global market.

What is a Cardan joint?

A Cardan joint is a mechanical device used to connect two shafts in relative motion. It transmits torque between the shafts and compensates for motion errors caused by angular variations. Its primary function is to ensure stable power transmission by allowing for variations in the angle between the two shafts, thereby avoiding failures or energy loss caused by misaligned shafts.

Working Principle: The core component of the Cardan joint is the cross shaft, which is connected between the two shafts using a universal joint design. When there is an angular difference between the drive shaft and the driven shaft, the Cardan joint automatically adjusts to maintain effective power transmission. This design makes it particularly suitable for applications such as automotive drives, agricultural machinery, and construction machinery, where power transmission is required and the angle between the two shafts varies.

Application Areas:

Cardan joints are widely used in:

Automotive: Particularly in automotive drive systems, Cardan joints connect the engine and wheels, ensuring efficient power transmission.

Industrial Equipment: In heavy equipment such as construction machinery, mining equipment, and papermaking machinery, Cardan joints ensure stable power transmission under high loads.

Agricultural Equipment: In equipment such as tractors and harvesters, Cardan joints are core components for power transmission.

Aerospace: Specialized, high-precision Cardan joints are used in precision instruments and aerospace equipment.

Advantages of China's Cardan Joint Manufacturing Process

China's Cardan Joint manufacturers have made significant advancements in process and technology in recent years. With their sophisticated production processes, innovative technologies, and efficient production capabilities, they have successfully driven China's rise in the global Cardan joint market. The advantages of China's Cardan Joint manufacturing are primarily reflected in the following aspects:

Advanced Materials Technology and R&D Capabilities

Material selection is the foundation of Cardan joint quality. Chinese manufacturers are increasingly focusing on the research and development and application of high-performance materials, commonly used materials including high-strength alloy steel, stainless steel, and aluminum alloy. These materials are wear-resistant and corrosion-resistant, capable of withstanding heavy loads and harsh operating environments.

In terms of R&D, Chinese manufacturers closely follow global technological trends, committed to developing higher-performance materials and coating technologies. For example, the use of advanced surface treatments such as galvanizing and heat treatment can significantly improve the wear resistance and service life of joints.

Precision Manufacturing and Processing Technology

Precision processing technology is one of the core strengths of China Cardan Joint manufacturing. With the continuous advancement of CNC (computer numerical control) technology, laser cutting, and 3D printing, Chinese Cardan joint manufacturers are able to achieve high-precision machining of components, thereby improving product quality and consistency. High-precision machining using CNC machine tools ensures that each Cardan joint meets extremely tight tolerances, meeting precision requirements.

Continuous innovations in precision casting technology enable manufacturers to produce more complex and high-strength Cardan joints, which are crucial for equipment subjected to high loads and harsh environments. Chinese manufacturers also widely utilize advanced heat treatment technologies to further enhance the wear resistance and strength of joints.

Efficient Production Processes and Scale

Production efficiency is another major advantage of China's manufacturing industry. In the production of Cardan joints, manufacturers rely on advanced automated production lines, robotic assembly technology, and a sophisticated management system to significantly improve production efficiency. Automated equipment enables precise batch production while maintaining consistent and stable product quality.

Large-scale production enables Chinese Cardan joints to not only meet market demand in terms of quantity, but also maintain low production costs during mass production. Chinese manufacturers, particularly in the global market, have secured a significant position with their cost-effective products.

Comprehensive Quality Control System

Chinese Cardan Joint manufacturers have established stringent standards and systems for quality control. From raw material procurement to final product testing, every step is rigorously controlled. Many manufacturers employ internationally recognized quality management systems, such as ISO 9001, to ensure compliance with standards at every stage of production.

During the production process, each joint undergoes multiple tests, including strength testing, fatigue testing, wear resistance testing, and high-temperature and high-pressure testing. Before shipment, manufacturers conduct comprehensive quality inspections to ensure stable operation under a variety of demanding operating conditions. This rigorous quality control system has earned global recognition for the performance and reliability of China Cardan Joints.

Innovative Design and Customized Services

With the diversification of customer needs, customized design has become another major advantage of China Cardan Joint manufacturing. Manufacturers can provide tailored joint solutions based on customer needs, offering personalized designs for various operating environments, including size, material, load capacity, and temperature resistance.

With the rise of intelligent design, some high-end Cardan joints have incorporated smart sensors that monitor their operating status and performance in real time. These smart joints not only enhance the user experience but also help customers better manage equipment maintenance, extending the lifespan of their equipment.

Innovative Trends in China Cardan Joint Design

In addition to its manufacturing process advantages, China Cardan Joint design is also undergoing continuous innovation. The following are the main trends in current Cardan joint design:

Intelligent Design

With the development of the internet and the Internet of Things (IoT), intelligent design in Cardan joints has become a new trend. Many high-end Cardan joints are now equipped with sensors that monitor operating conditions such as temperature, pressure, and vibration in real time and transmit this data to remote control systems. This not only enhances the functionality of Cardan joints but also improves equipment safety and maintainability.

Lightweight Design

In modern machinery, lightweight design is increasingly becoming a key factor in improving efficiency and energy conservation. China Cardan Joint manufacturers utilize lightweight, high-strength materials and optimize the joint's structural design. This ensures that the joint maintains high load capacity while also reducing the overall weight of the equipment.

High Load-Bearing Capacity

Modern machinery, especially heavy machinery and high-load applications, places increasingly high demands on the load-bearing capacity of Cardan joints. By enhancing the structural strength of Cardan joints, using highly wear-resistant materials, and optimizing their design, manufacturers ensure that the joints can operate stably and long-term under high loads and harsh operating conditions.

English

English 中文简体

中文简体