Toyo Universal Joint helps the automation industry and promotes the development of precision machinery

Content

- 1 Application of Toyo Universal Joint in the Automation Industry

- 1.1 Automobile manufacturing industry: improve production efficiency and ensure product quality

- 1.2 Electronic manufacturing industry: precision control to ensure product quality

- 1.3 Mechanical processing and CNC equipment: optimize precision processing and improve production efficiency

- 1.4 Food processing and packaging industry: cope with harsh working environment and maintain stable operation

- 1.5 Robotics and Automation Equipment: Promoting High-Precision Manufacturing

- 2 Toyo Universal Joint promotes technological progress in the automation industry

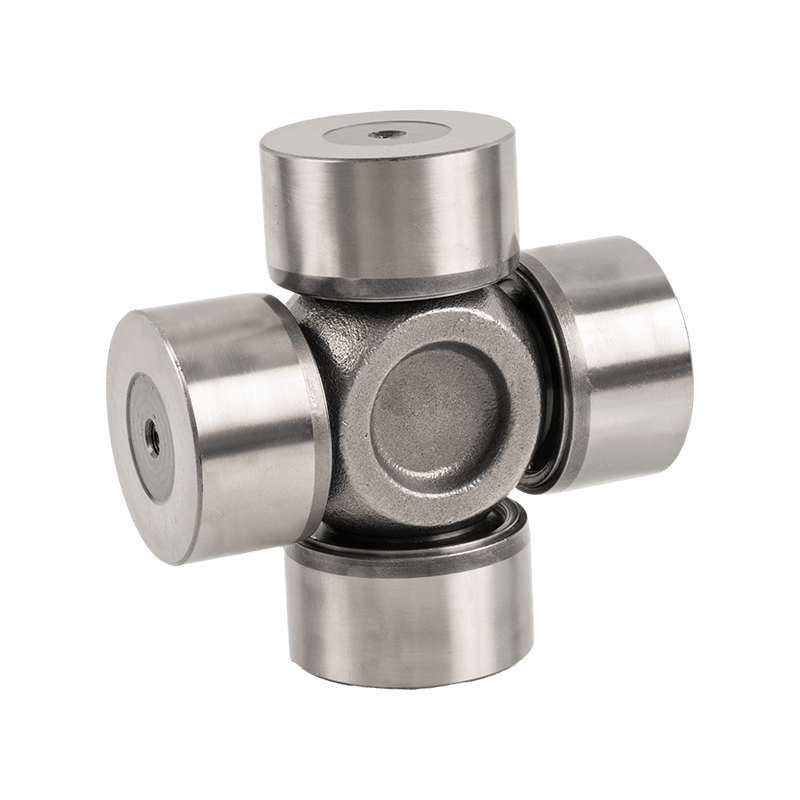

With the continuous upgrading of the global manufacturing industry, the application of automation technology in all walks of life has become more and more popular. Especially in the field of precision machinery and efficient production, how to maintain the efficiency, precision and stability of production equipment has become the goal pursued by enterprises. In these fields, the core component of the transmission system, the universal joint, plays a vital role. With its technological advantages, Toyo Universal Joint has become an indispensable key component in the automation industry, and has made great contributions to improving production line efficiency, optimizing mechanical equipment performance and promoting the development of precision machinery.

Application of Toyo Universal Joint in the Automation Industry

Automobile manufacturing industry: improve production efficiency and ensure product quality

Automobile manufacturing is one of the widely used fields in the global automation industry. With the improvement of intelligence and automation, the demand for precision equipment in the automobile production process continues to increase, especially in welding, painting, assembly and other process links, the reliability and precision of the transmission system are particularly important.

With its high-precision design and load-bearing capacity, Toyo Universal Joint is widely used in automated production lines. As a connecting device, Toyo Universal Joint can stably transmit power and effectively reduce errors caused by factors such as speed and load changes, thereby ensuring the smooth operation of the production line. This feature is crucial in high-speed, high-load production environments, effectively avoiding equipment failures caused by errors.

The high temperature resistance and corrosion resistance of Toyo Universal Joint also enable it to maintain long-term stable working conditions in various environments of automobile manufacturing. For example, during the painting process, the production line needs to experience a high temperature environment, and the high temperature resistant design of Toyo Universal Joint ensures that it can still work efficiently under such conditions, extending the service life of the equipment and reducing maintenance costs.

Electronic manufacturing industry: precision control to ensure product quality

The manufacturing process of electronic products often requires extremely high precision. In the high-speed, high-precision automated production process, any slight transmission error may result in substandard quality of the final product. Therefore, ensuring the stability and accuracy of the transmission system of mechanical equipment becomes the key to ensuring product quality.

With its precise power transmission and low friction design, Toyo Universal Joint has helped the electronics manufacturing industry solve this problem. Whether in SMT placement machines, laser cutting machines or precision assembly equipment, Toyo Universal Joint can ensure smooth operation of the equipment, reduce mechanical vibration and noise, and improve product assembly accuracy. Its high corrosion resistance enables it to adapt to complex environments such as moisture and chemical corrosion, while ensuring the continuous and efficient operation of the production line, avoiding equipment failures caused by corrosion.

In the manufacturing of printed circuit boards (PCBs), electronic component assembly and other links, the high-precision design of Toyo Universal Joint also helps the equipment achieve higher assembly accuracy, thereby reducing the defective rate and improving the quality and consistency of electronic products.

Mechanical processing and CNC equipment: optimize precision processing and improve production efficiency

Mechanical processing and CNC equipment play a vital role in the field of precision manufacturing, especially in the manufacture of high-precision parts and complex structures. The stability of the equipment and the accuracy of the transmission system directly affect the processing quality and efficiency. CNC machine tools require an efficient and stable transmission system during operation. Any transmission error may reduce the processing accuracy and affect the quality of the final product.

With its ultra-high precision and high-load resistance, Toyo Universal Joint has become an indispensable key component in CNC machine tools and automated processing equipment. It can stably transmit power at high speed and high load, reduce precision fluctuations caused by vibration and mechanical errors, and ensure high precision and high efficiency in precision parts processing.

In the field of precision processing and high-end manufacturing, the performance of Toyo Universal Joint provides stable power support for CNC equipment, reduces the occurrence of equipment failures, and improves the overall efficiency of the production line. Its high wear resistance and long-term stability also greatly extend the service life of the equipment and reduce the maintenance costs of the enterprise.

Food processing and packaging industry: cope with harsh working environment and maintain stable operation

Automated production lines in the food processing and packaging industry often face harsh working environments such as humidity, high temperature and high pressure. In order to ensure the stability of the production line in such an environment, the equipment needs to have higher durability and adaptability. Traditional connection components often cannot withstand such a complex working environment, which can easily cause equipment damage or shutdown.

Toyo Universal Joint has been widely used in the food processing and packaging industry due to its high temperature resistance, corrosion resistance and high load bearing capacity. It can withstand moisture, temperature fluctuations and chemical corrosion in the production line, ensuring the stable operation of the equipment in harsh environments. In packaging, sorting and assembly, Toyo Universal Joint can provide efficient power transmission, ensuring that the equipment is not affected by the external environment and continuously and efficiently completes production tasks.

Robotics and Automation Equipment: Promoting High-Precision Manufacturing

With the widespread application of industrial robots and automation equipment, the demand for precision transmission systems is increasing. Automation equipment not only needs to have efficient power transmission, but also needs to ensure accuracy and stability during high-speed operation. With its high precision and high durability, Toyo Universal Joint has become an indispensable core component in modern robot systems.

The high-efficiency transmission and impact resistance of Toyo Universal Joint enable it to work stably in automation equipment, ensuring that the robot system maintains efficient and stable operation in complex environments. Under high-load and fast-running conditions, Toyo Universal Joint effectively avoids mechanical errors and vibrations through its precise design, providing reliable guarantees for the high-precision operation of automation equipment.

Toyo Universal Joint promotes technological progress in the automation industry

Toyo Universal Joint has not only been widely used in various industries, but also promoted the progress of the entire automation industry through its technological innovation. The following is the role of Toyo Universal Joint in promoting the development of the automation industry:

Improving production efficiency and precision

Toyo Universal Joint reduces the transmission error of the equipment by optimizing the transmission system, ensuring the efficient operation of mechanical equipment under high-speed and high-load conditions. This feature helps the automated production line achieve higher production efficiency and improves the processing accuracy of the product. Especially in the field of precision manufacturing, the application of Toyo Universal Joint helps companies improve the overall production level.

Extend equipment service life and reduce maintenance costs

Due to its high durability and stability, Toyo Universal Joint can effectively extend the service life of the equipment and reduce the failure rate and downtime of the equipment. This not only improves the stability of the production line, but also reduces the maintenance cost of the enterprise, thereby improving the economic benefits of production.

Promote the development of high-end manufacturing industry

As the global manufacturing industry transforms towards high-end and intelligent, the demand for precision equipment and efficient production systems is increasing. The Toyo Universal Joint has promoted the development of high-end manufacturing through its high precision and performance. In the fields of automobiles, electronics, aviation, machining, etc., the wide application of the Toyo Universal Joint enables high-precision equipment to operate stably in more complex environments, further promoting the development of precision machinery manufacturing technology.

English

English 中文简体

中文简体