The important role of Toyo Universal Joint in precision engineering

Content

In precision engineering, the stability and accuracy of the transmission system are one of the key criteria for measuring equipment performance. Especially in areas that require long-term high-load operation, the quality of transmission components directly affects the efficiency and reliability of the entire system. In this context, Toyo Universal Joint plays an irreplaceable role in various types of high-precision engineering with its technical advantages. Whether in aerospace, medical equipment, optical instruments, or precision machinery manufacturing, Toyo Universal Joint has ensured the efficient operation and long-term stability of the system with its unique technical advantages.

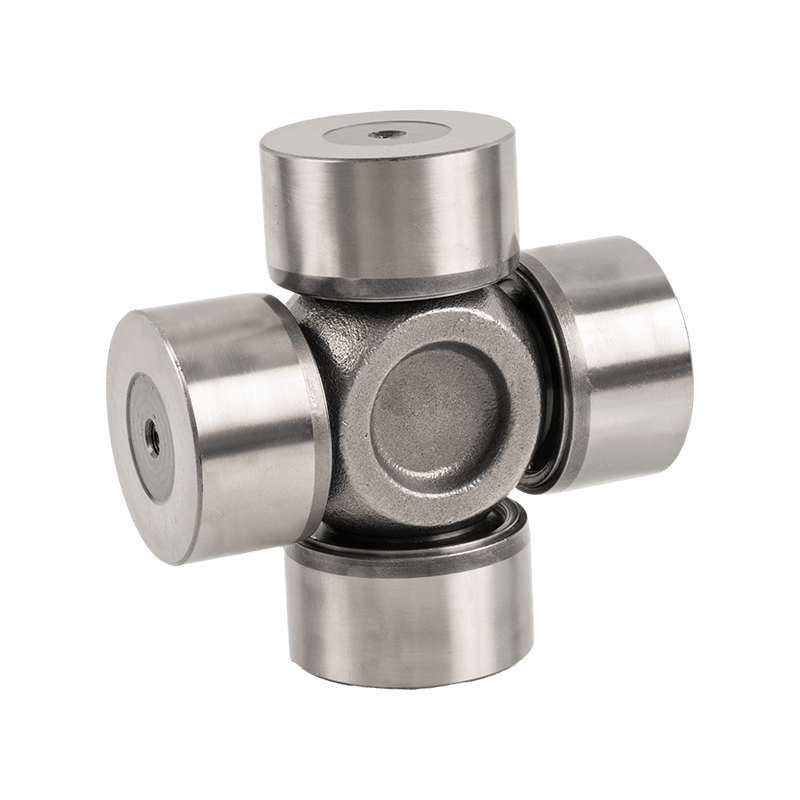

Overview of Toyo Universal Joint

Toyo Universal Joint is a key component that connects two rotating shafts and transmits power. It is widely used in various types of mechanical equipment. It can efficiently and smoothly transmit torque at different angles to avoid system failures caused by angle errors or unbalanced loads. Compared with traditional universal joints, Toyo Universal Joint uses higher-strength materials and more sophisticated processes. It can operate stably for a long time under high loads, high speeds and high temperatures, greatly improving the reliability of the system.

The key to Toyo Universal Joint's ability to occupy such an important position in precision engineering lies in its unique technical advantages. Next, we will analyze these advantages in detail and show how they make the Toyo Universal Joint a core component in the field of precision engineering.

Technical advantages of Toyo Universal Joint

High-strength materials and durability

One of the biggest technical advantages of Toyo Universal Joint is its selected high-strength alloy materials. Through strict material selection and advanced heat treatment processes, Toyo Universal Joint can significantly improve its fatigue resistance, wear resistance and high temperature resistance. High-strength alloy materials enable the universal joint to withstand a wide range of load changes and maintain stable power transmission even under load conditions. Whether it is under high-speed rotation or high-load operation, Toyo Universal Joint can ensure the efficient operation of the system and reduce equipment failures and maintenance requirements.

This advantage is particularly reflected in the fields of aerospace, heavy machinery and medical equipment. For example, in the power transmission system of aircraft engines, Toyo Universal Joint can operate stably under extremely high temperatures and pressures, ensuring the coordinated operation of engine components, thereby improving flight safety.

High precision and transmission stability

In precision engineering, high-precision requirements for the system are crucial. Toyo Universal Joint adopts advanced manufacturing technology and high-precision design, which can achieve extremely small errors during the transmission process and ensure the high precision of the transmission system. In precision equipment, especially high-precision machine tools, medical equipment and optical instruments, the high-precision transmission characteristics of the universal joint ensure the stability and reliability of the equipment.

In high-precision CNC machine tools, the universal joint needs to connect the spindle and the motor to maintain extremely high precision and prevent errors from affecting the cutting effect. The design of Toyo Universal Joint ensures that the transmission accuracy is still correct even under high-speed operation and heavy loads, ensuring that every workpiece can be accurately processed and meet strict manufacturing standards.

High temperature resistance and environmental adaptability

Many equipment in precision engineering is often in extreme working environments, especially in aerospace, energy and some high-temperature equipment. Toyo Universal Joint adopts high-temperature resistant materials and advanced surface treatment technology, which enables it to work stably in high-temperature environments. This feature enables it to maintain performance in harsh environments and effectively avoid transmission failure caused by temperature fluctuations.

Taking aerospace as an example, the high temperature environment of the engine and transmission system requires the universal joint to be able to withstand extremely high temperature changes, and the Toyo Universal Joint can stably transmit power in this case to ensure the safety of the aircraft. In industrial machinery, its high temperature resistance also enables it to operate stably for a long time in high temperature places such as metallurgy and mining to avoid equipment failure.

Low noise and low vibration

In some precision engineering fields that require low noise and low vibration, the low vibration characteristics of the Toyo Universal Joint make it an ideal choice. For example, in precision equipment such as medical equipment and optical instruments, any slight vibration or noise will affect the performance and operating accuracy of the equipment. The Toyo Universal Joint significantly reduces the noise and vibration in mechanical operation through fine manufacturing processes and optimized design, thereby providing a quieter and more stable working environment.

Especially in medical equipment, such as surgical robots, MRI equipment, etc., the Toyo Universal Joint can effectively reduce the noise and vibration caused by unstable power transmission, ensure the precise operation of the equipment at the microscopic level, and ensure the safety and treatment effect of patients.

Corrosion resistance and extended service life

The corrosion resistance of Toyo Universal Joint is also excellent. It uses a special surface treatment process to enable it to maintain stability for a long time in humid or corrosive environments. This feature is particularly important in fields such as marine engineering and petrochemicals. Universal joints can resist corrosion sources such as salt water and chemicals, extend their service life and reduce failures and maintenance costs caused by corrosion.

For example, in offshore oil and gas platforms or marine detection equipment, Toyo Universal Joint can withstand the erosion of seawater and provide stable power transmission in extremely harsh environments, thereby ensuring the safe and reliable operation of the equipment.

Application of Toyo Universal Joint in Precision Engineering

These technical advantages of Toyo Universal Joint make it widely used in many fields of precision engineering. Here are some specific application cases:

Aerospace industry

In the field of aerospace, Toyo Universal Joint is mainly used in the transmission system of aircraft engines. It can withstand extremely high temperature and pressure changes to ensure stable operation of the engine during flight. In addition, Toyo Universal Joint is also widely used in satellites, drones and other equipment to ensure high-precision power transmission and stable flight control.

Medical equipment

In the medical field, Toyo Universal Joint is used in high-end medical equipment such as surgical robots, MRI, and CT scanners. Its high precision, low noise and high temperature resistance enable these devices to provide stable and reliable services in complex environments, ensuring the accuracy of medical operations and the safety of patients.

High-precision machinery manufacturing

In precision machine tools, laser cutting machines and other equipment, Toyo Universal Joint is a key component that ensures efficient and accurate power transmission. Its high wear resistance and high load resistance ensure that these devices remain stable under long-term high-load operation and can continue to provide accurate power transmission under various conditions.

English

English 中文简体

中文简体